Pyroelectric infrared sensor

A pyroelectric infrared and sensor technology, applied in the field of photosensitive devices, can solve problems such as inability to work normally, and achieve the effects of solving the inability to work normally, reducing background noise, and having a long detection distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

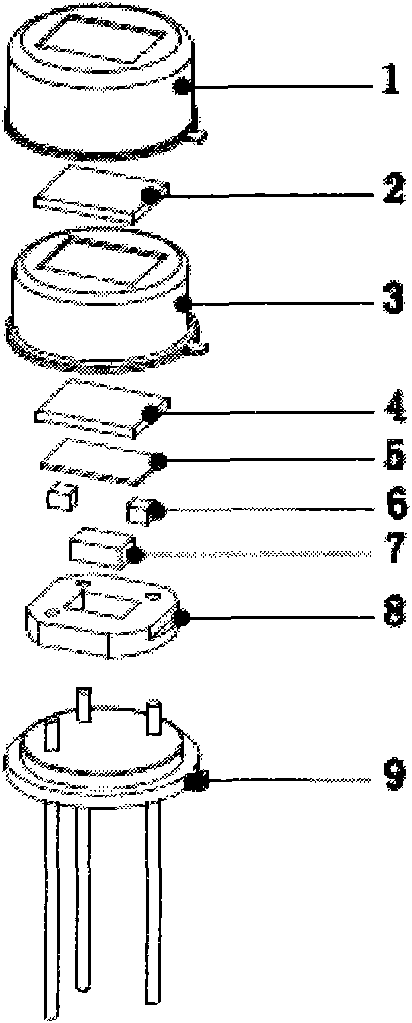

[0011] Such as figure 1 with figure 2 As shown, the pyroelectric infrared sensor includes an annular tube cap 1 with an inner diameter of 8.25mm, and the annular tube cap 1 is covered on the annular tube cap 3, and the window of the annular tube cap 1 is inlaid with Infrared filter 2, an infrared filter 4 is inlaid in the window of the annular tube cap 3, the distance between the lower surface of the infrared filter 2 and the upper surface of the infrared filter 4 is 1 mm, and the detection sensitivity The element 5 is on the holder 6, the holder 6 is supported between the ceramic substrate 8 and the detection sensitive element 5, the triode 7 is placed in the through hole provided in the middle of the ceramic substrate 8, and the ceramic substrate 8 is placed in the tube On the seat 9, the circular tube cap 3 is covered on the tube seat 9, and the circular tube cap 1 is covered on the circular tube cap 3.

[0012] The pyroelectric infrared sensor is composed of three parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com