Graphene-based array type flexible pressure distribution sensor and preparation method thereof

A pressure distribution and graphene technology, which is applied to the measurement of properties and forces of piezoelectric resistance materials, can solve the problems of limited use range of pressure sensors, and achieve the effect of improving the use range, long service life and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific drawings and embodiments.

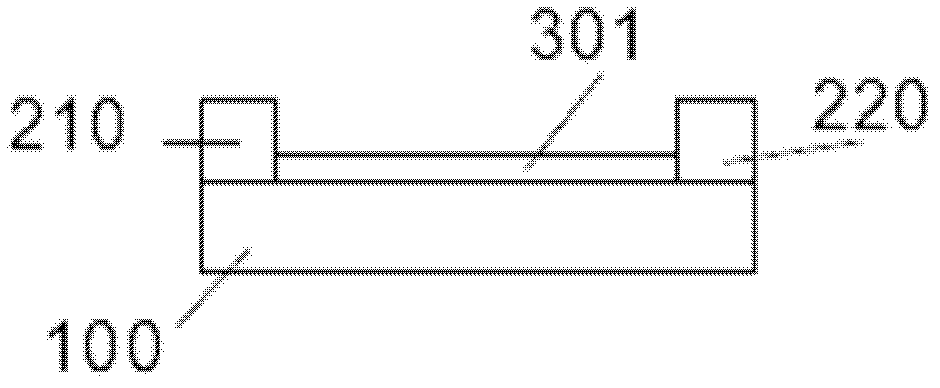

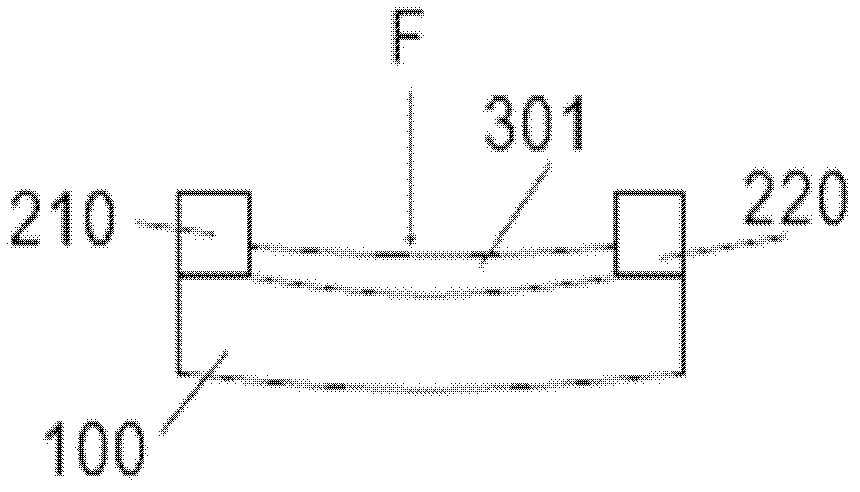

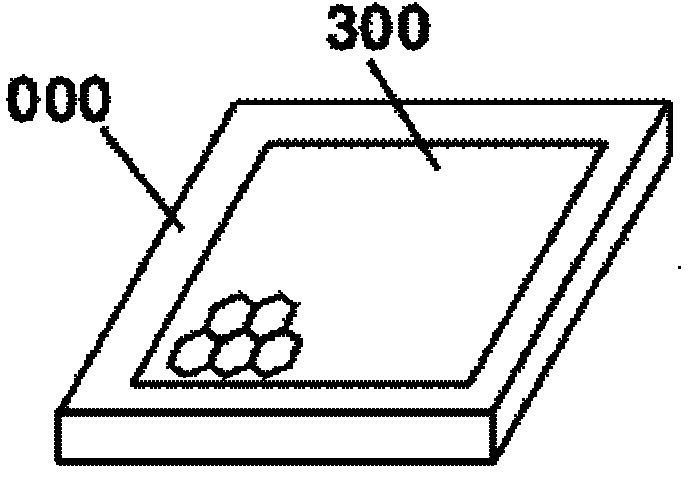

[0038] like figure 1 and Figure 11 Shown: the graphene-based array flexible pressure distribution sensor includes a flexible substrate 100 and a graphene film array 301 located on the flexible substrate 100, and the graphene film array 301 includes at least one graphene conductive body 310, the graphene conductor 310 is electrically connected to the row electrode 210 and the column electrode 220 on the flexible substrate 100; the graphene film array 301 is obtained by the graphene film 300 by electron beam etching, and forms a number of mutually independent Graphene conductor 310. in, figure 1 shows a structure in which a single graphene conductor 310 is set on the flexible substrate 1, that is, there is only one graphene conductor 310 in the graphene film array 301, Figure 11 shows a structure in which several graphene conductors 310 are disposed on a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com