In-place gas measurement method and in-place gas measurement device

A gas measurement and gas technology, which is applied in the field of on-site gas measurement, can solve problems such as instability and large measurement errors, and achieve the effect of small measurement errors and stable measurement optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

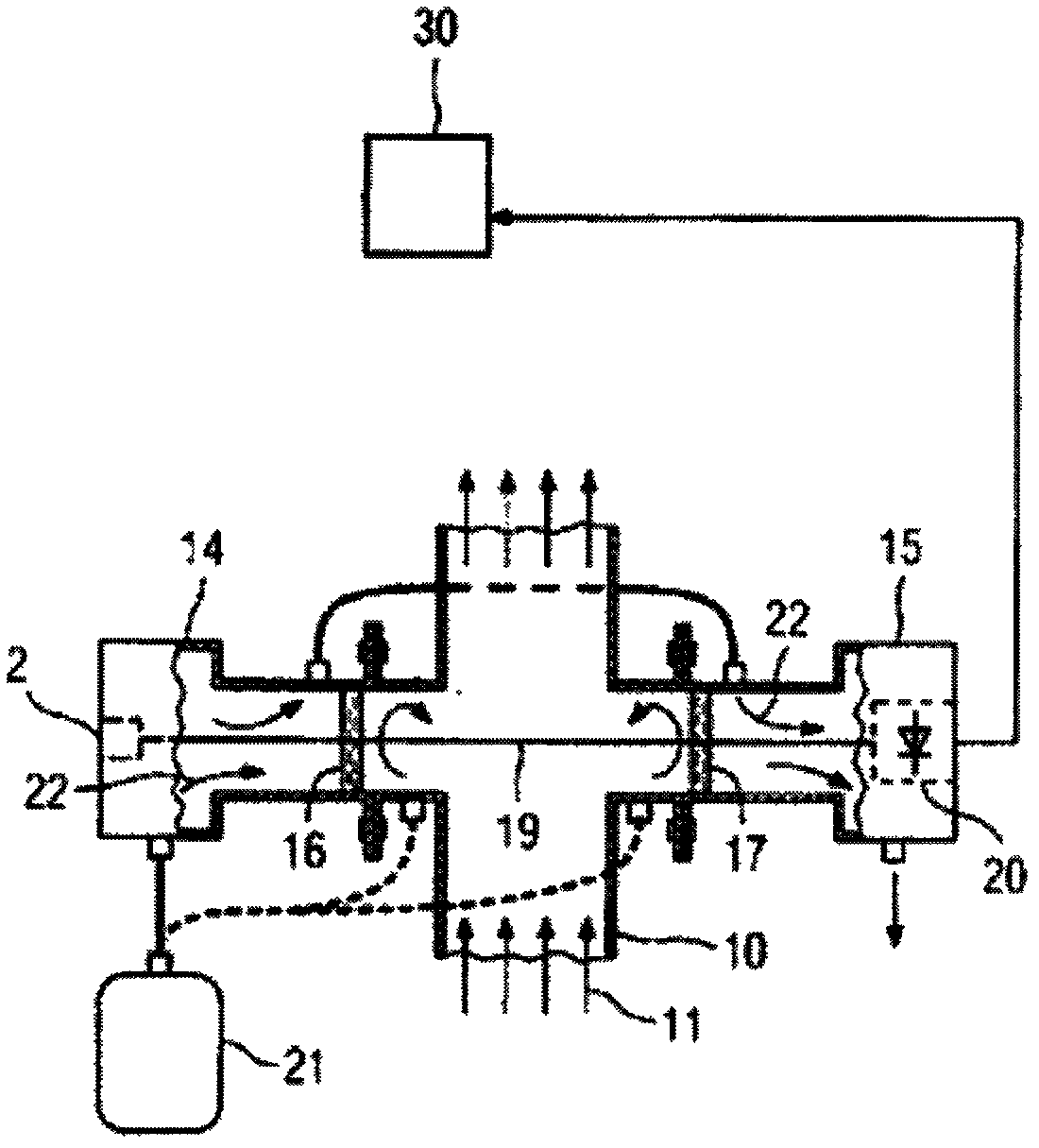

[0041] figure 2 The basic structure diagram of the on-site gas measuring device according to the embodiment of the present invention is schematically given. Such as figure 2 As shown, the gas measuring device includes:

[0042] Laser and drive circuit 2 , detector 20 , analysis unit 30 and purge unit 21 . Windows 16 and 17 are provided on the measurement channel for isolating the process gas 11 .

[0043] Gas interfaces 23, 24, the gas interfaces 23, 24 are respectively arranged at the first gas discharge pipeline 10 provided by the purging unit 21, for allowing the second gas to pass through the interface and along the process in the pipeline. The flow direction of the gas 11 is discharged into the pipeline, thereby forming a gas wall separating the first gas and the process gas, and maintaining the stability of the measurement optical path between the two gas walls; preferably, the width of the gas interface is between [0.1mm, 1.0mm].

[0044] a gas supply unit 22, th...

Embodiment 2

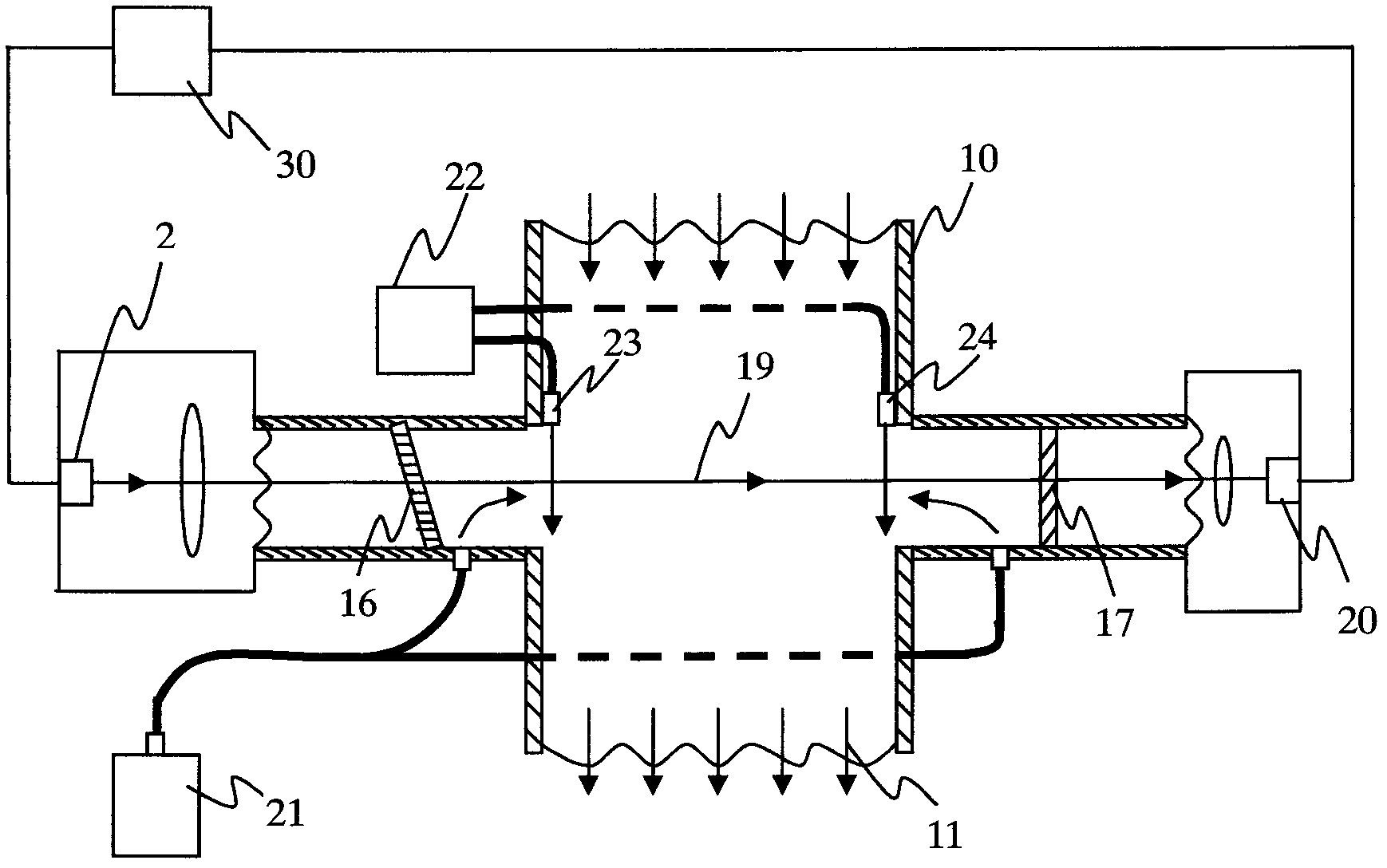

[0057] image 3 The basic structure diagram of the on-site gas measuring device according to the embodiment of the present invention is schematically given. Such as image 3 As shown, the difference between the gas measuring device and embodiment 1 is:

[0058] The measuring device further includes an inner tube for passing the measuring beam 19 and the first gas, and the gas interfaces 23 and 24 are arranged at the ends of the inner tube deep into the pipeline. Optionally, gas passages are provided on the outside of said inner tube.

Embodiment 3

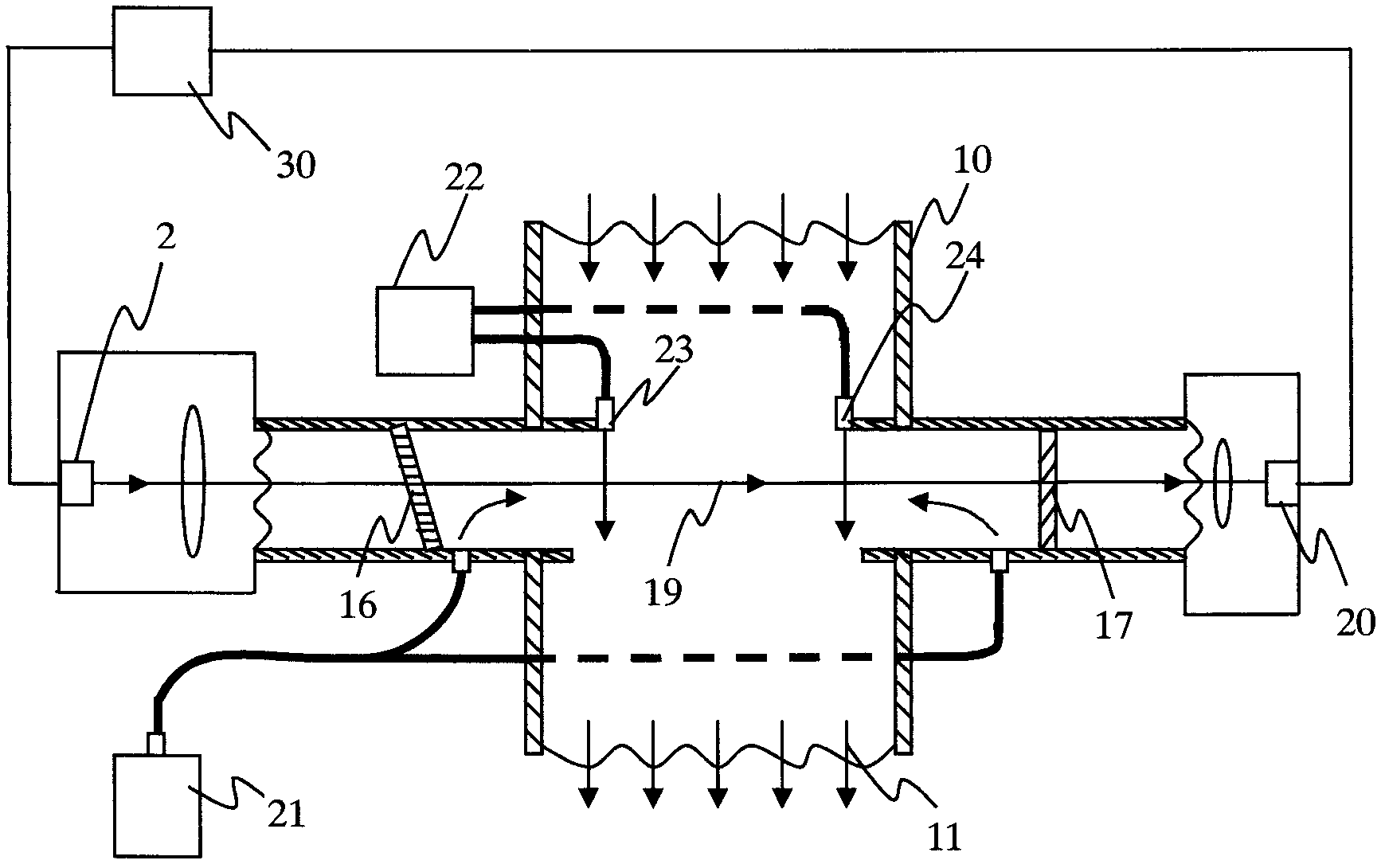

[0060] An application example of the measurement device and method according to Embodiment 2 of the present invention in the detection of hydrogen sulfide in natural gas pipelines.

[0061] In this application example, the light source is a VCSEL laser, and the emitted wavelength contains the absorption spectrum line 1588nm corresponding to hydrogen sulfide, the flow velocity of the first gas is 2m / s, and the flow velocity of the process gas in the pipeline is 0.1m / s , the width of the gas interface is 0.2mm, and the flow rate of the second gas passing through the gas interface is 120m / s. At this time, the second gas forms a gas wall separating the first gas and the process gas, as shown in Figure 4 As shown, the measurement optical path is between the two gas walls, which ensures the stability of the measurement optical path, thereby reducing the measurement error.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com