Device for detecting gas in single-end in-situ pipeline, and working method thereof

A gas detection and pipeline technology, applied in the direction of measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc., can solve problems such as low reliability, abnormal measurement of instruments, complex pretreatment structure, etc., to improve operation The effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

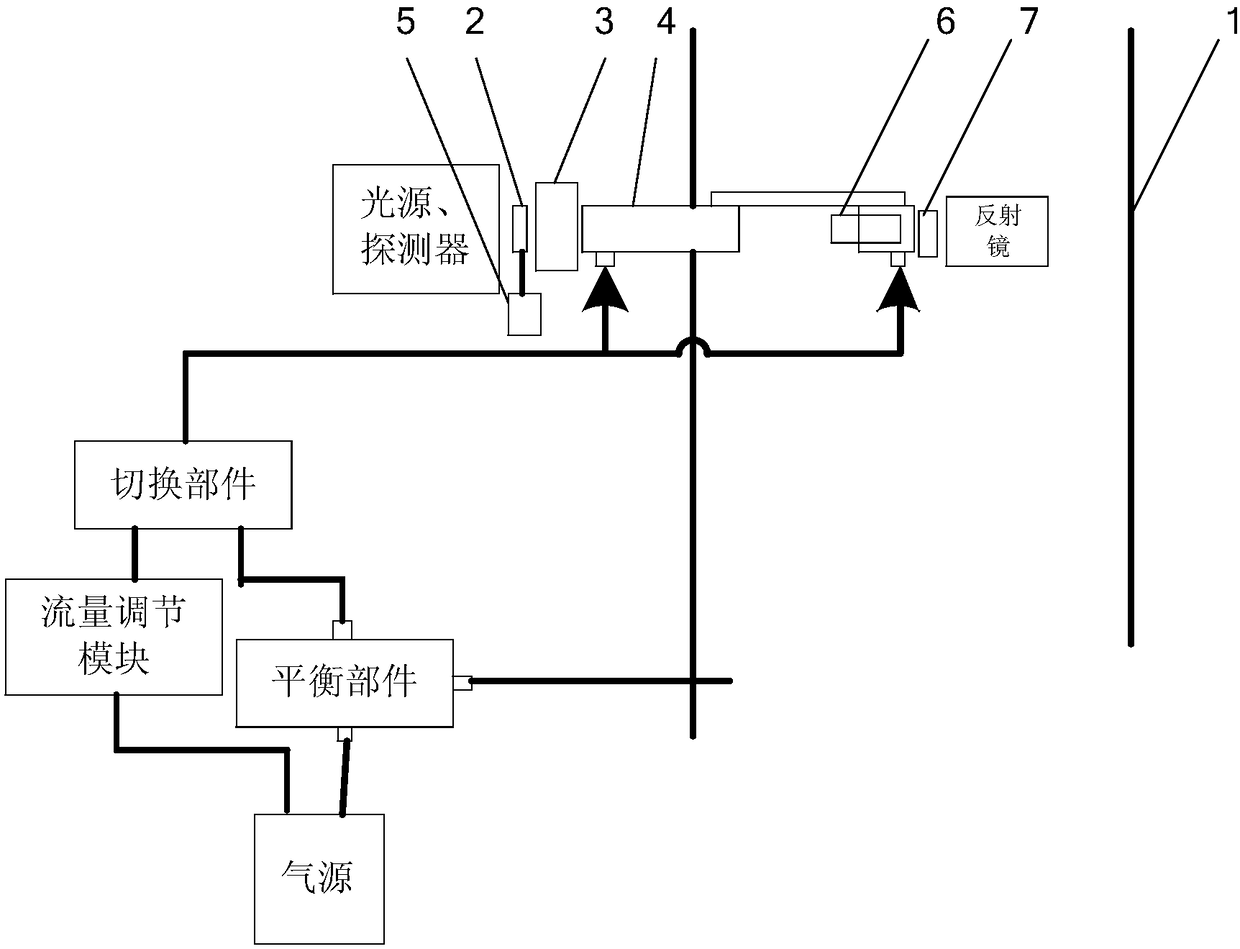

[0049] figure 1 A schematic diagram of the structure of the single-end in-situ gas detection device in the pipeline according to the embodiment of the present invention is schematically given, as shown in figure 1 As shown, the single-end in-situ pipeline gas detection device includes:

[0050]A light source, a detector, and a first tube 4 extending into the pipeline 1, the part of the first tube 4 protruding into the pipeline 1 has a gap facing away from the airflow direction in the pipeline; the first tube has The part of the notch is arc-shaped or V-shaped or [-shaped in section along the airflow direction in the pipeline;

[0051] The first isolation part 2, such as a glass slide, is arranged on the light path of the measurement light emitted by the light source to pass through the measurement light, and isolates the light source and the gas in the pipeline; along the In the direction of the measuring light, one or both sides of the first isolation member have elastic se...

Embodiment 2

[0075] An application example of the single-end in-situ pipeline gas detection device and its working method in the detection of gas concentration in pipelines according to Embodiment 1 of the present invention.

[0076] In this application example, the in-situ pipeline gas detection device includes:

[0077] A light source, such as a tunable semiconductor laser, the measurement light emitted by the light source passes through the purge unit on one side of the pipeline and then enters the pipeline, interacts with the gas in the pipeline and then passes through the purge unit on the other side of the pipeline After being received by the detector;

[0078] a detector, the detector converts the received optical signal into an electrical signal; the light source and the detector are arranged on opposite sides of the pipeline;

[0079] An analysis unit, the analysis unit uses absorption spectroscopy to process the electrical signal, so as to know the gas content in the pipeline; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com