Test method for measuring humidification, disintegration and dispersion of soil mass

A test method and soil technology, applied in disintegration and dispersion tests, and in the field of measuring soil moisture, can solve the problems of large measurement errors, many human factors, inaccurate calculation results, etc., and achieve clear meaning of physical concepts, Reduce the interference of human factors, and the effect of accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] equipment:

[0062] 1. Bracket: a test bracket composed of a titration table and a cross, which can hang a digital push-pull gauge.

[0063] 2. Beaker: 2000ml beaker.

[0064] 3. Stencil: 10cm×10cm, metal square grid, hole 1cm2, can be hung under the digital push-pull gauge.

[0065] 4. Sample: a cube with side length 5cm×5cm×5cm.

[0066] 5. Digital display push-pull gauge: use a digital display push-pull gauge with a range of 10N or 20N and an accuracy of 0.005N or 0.01N, which can be connected to a computer to simultaneously display the test force curve and record the test process.

[0067] 6. Electronic computer: Commonly used electronic computer is connected with the digital push-pull force meter to record and save the test data.

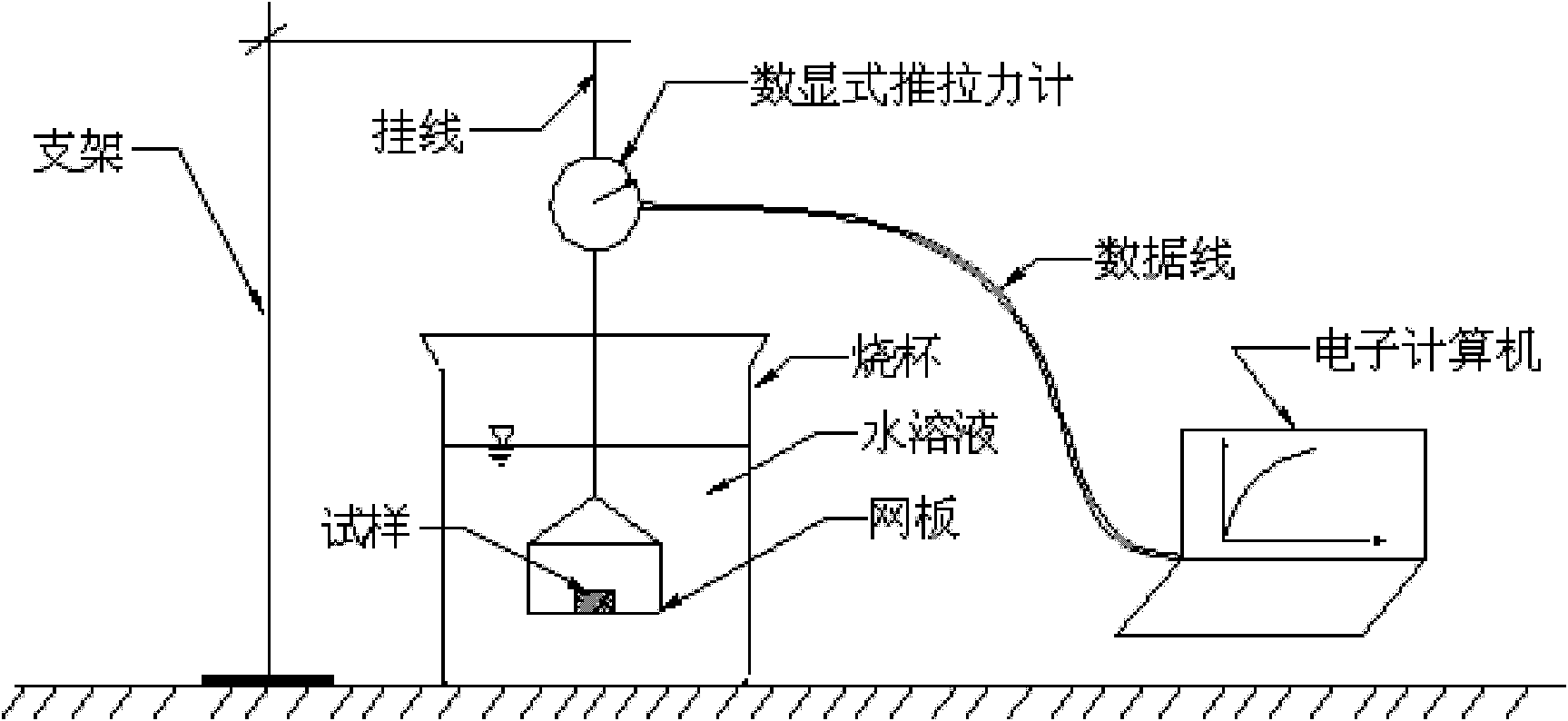

[0068] Assembly method (see figure 1 ):

[0069] 1. Connect the digital push-pull force gauge to the computer with a data cable.

[0070] 2. Stabilize the bracket, hang the digital display push-pull gauge on the bracket, and then han...

Embodiment 2

[0092] equipment:

[0093] 1. Bracket: The test bracket is composed of a titration table and a cross, which can hang the mesh plate.

[0094] 2. Beaker: 2000ml beaker.

[0095] 3. Mesh plate: 10cm×10cm, metal square grid, hole 1cm2, can be hung under the bracket.

[0096] 4. Sample: a cube with side length 5cm×5cm×5cm.

[0097] 5. Electronic balance: use an electronic balance with a measuring range of 1kg or 2kg and an accuracy of 0.01g or 0.05g, which can be connected to a computer through a data cable to simultaneously display and record changes in mass.

[0098] 6. Electronic computer: Commonly used electronic computer, connected with electronic balance, records and saves test data.

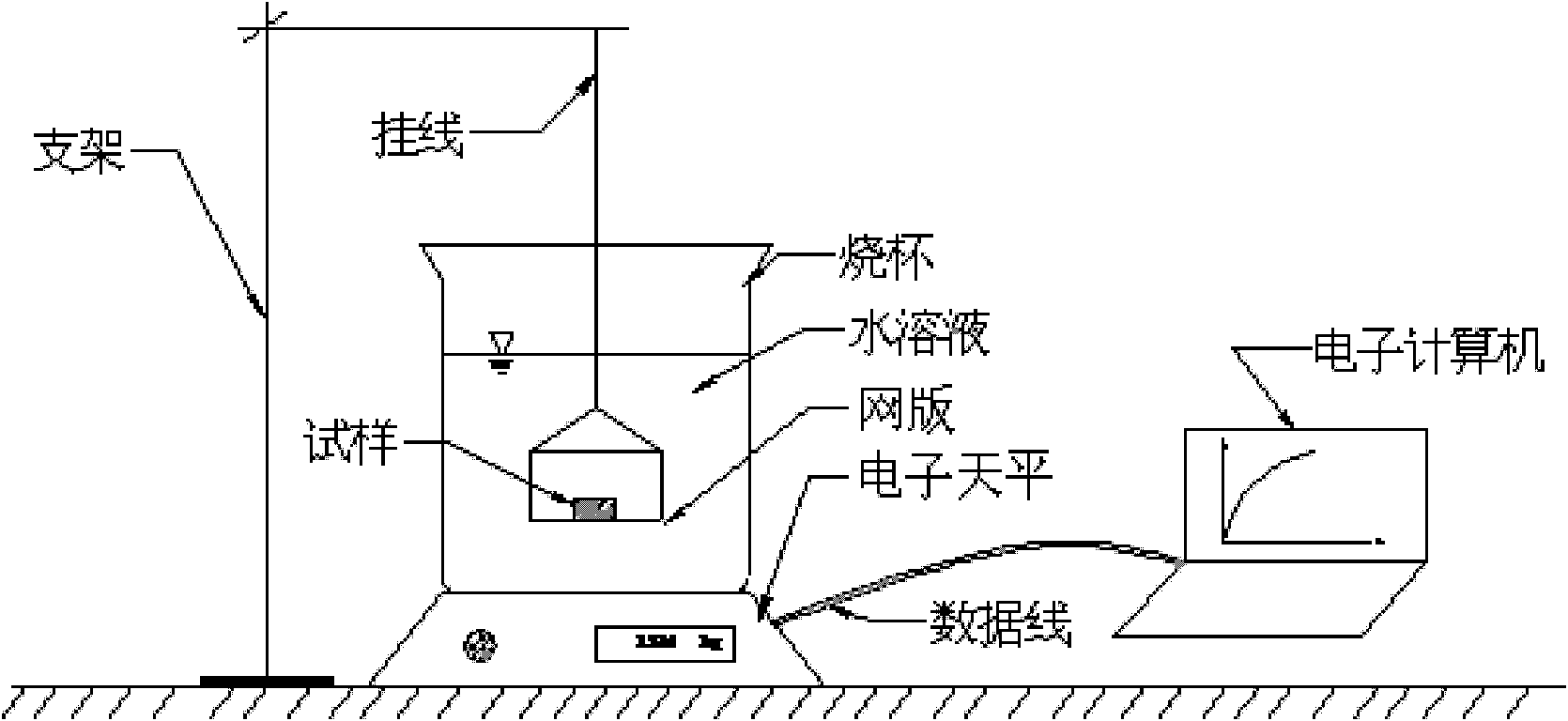

[0099] Assembly method (see figure 2 ):

[0100] 1. Connect the electronic balance to the electronic computer through the data line.

[0101] 2. Stabilize the bracket, and hang the mesh panel on the bracket with a hanging wire.

[0102] 3. Put the beaker containing the aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com