High-voltage AC (alternate current) and DC (direct current) voltage divider with heat dissipation structure

A technology of DC voltage divider and heat dissipation structure, applied in the direction of voltage divider, etc., can solve the problem of unsatisfactory heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

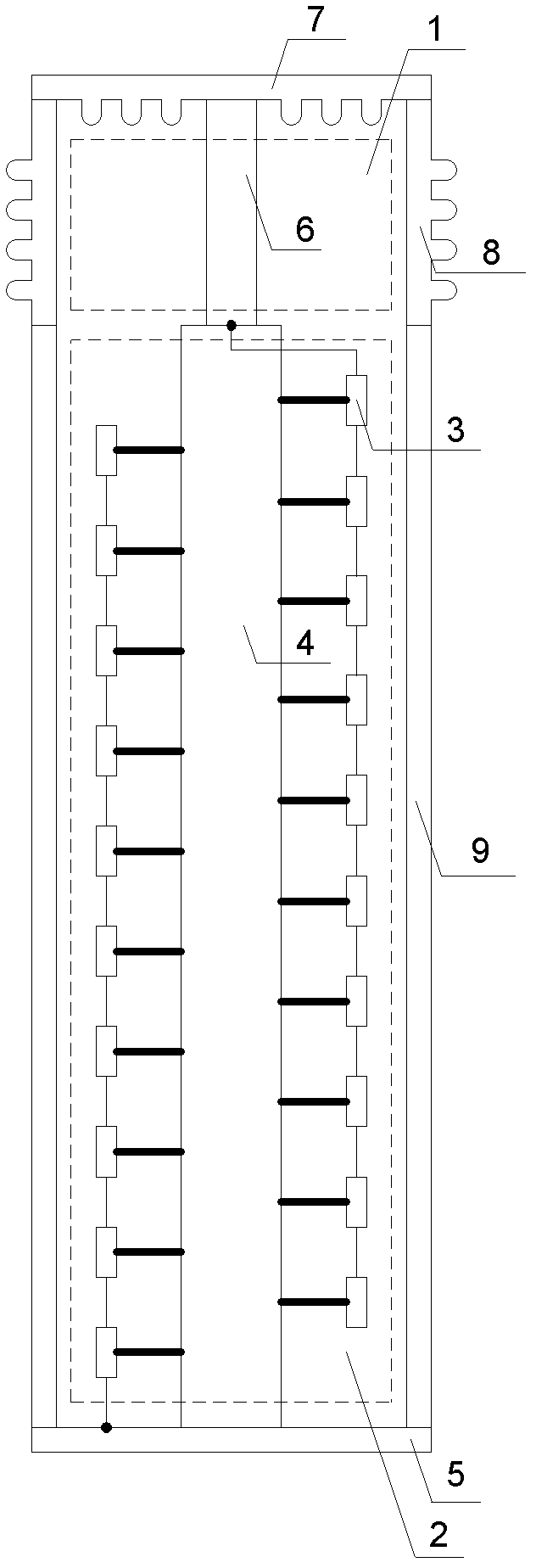

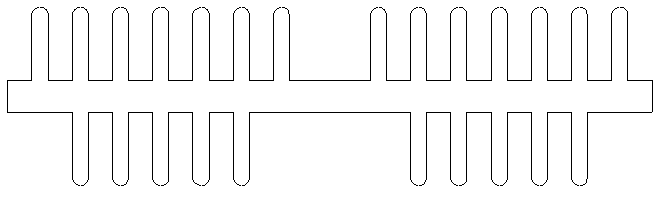

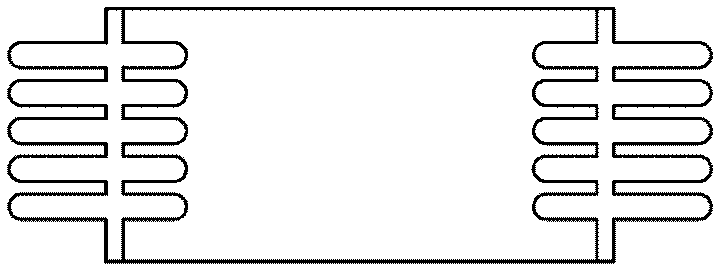

[0014] Marks in the drawings: 1—heat dissipation area, 2—working area, 3—resistor string, 4—insulated inner cylinder, 5—chassis, 6—conductive rod, 7—cover plate, 8—conductive outer cylinder, 9—insulation Outer cylinder.

[0015] Embodiments of the present invention will be further described below in conjunction with accompanying drawings: figure 1 , the present invention is made up of resistance string 3, insulating inner cylinder 4, chassis 5, conductive rod 6, cover plate 7, conductive outer cylinder 8, insulating outer cylinder 9. The area surrounded by the cover plate 7 and the conductive outer cylinder 8 forms a heat dissipation area 1 . In this embodiment, heat sinks are only added on the lower surface of the cover plate 7 and the outer surface of the conductive outer cylinder 8. When it is necessary to further improve the heat dissipation efficiency, additional fins can be added on the upper surface of the cover plate 7 and the inner surface of the conductive outer cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com