Failure Analysis Methods for Semiconductor Devices

A failure analysis and semiconductor technology, applied in the field of failure analysis of semiconductor devices, can solve problems such as long time consumption, high cost, and solution failure, and achieve the effect of saving time, improving efficiency and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

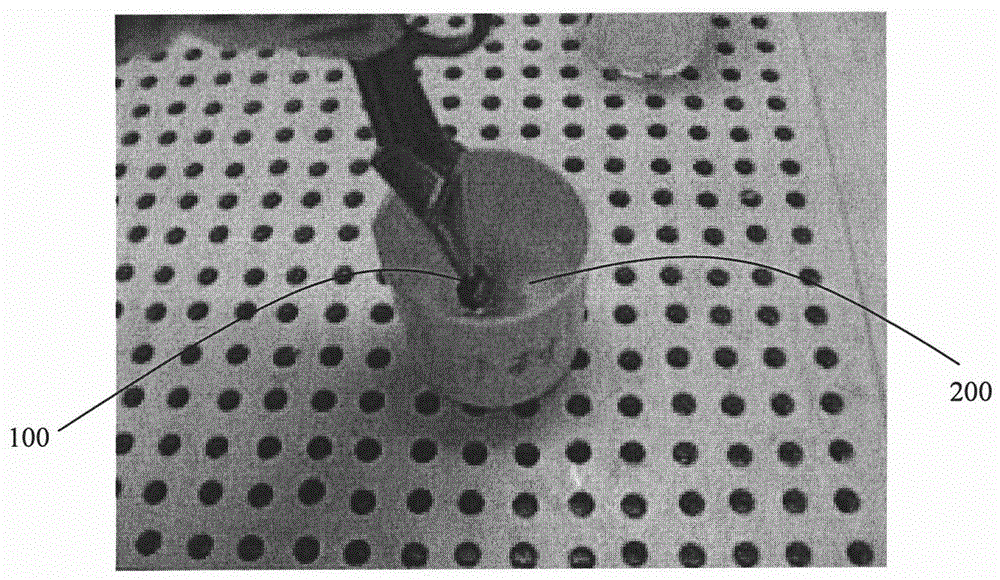

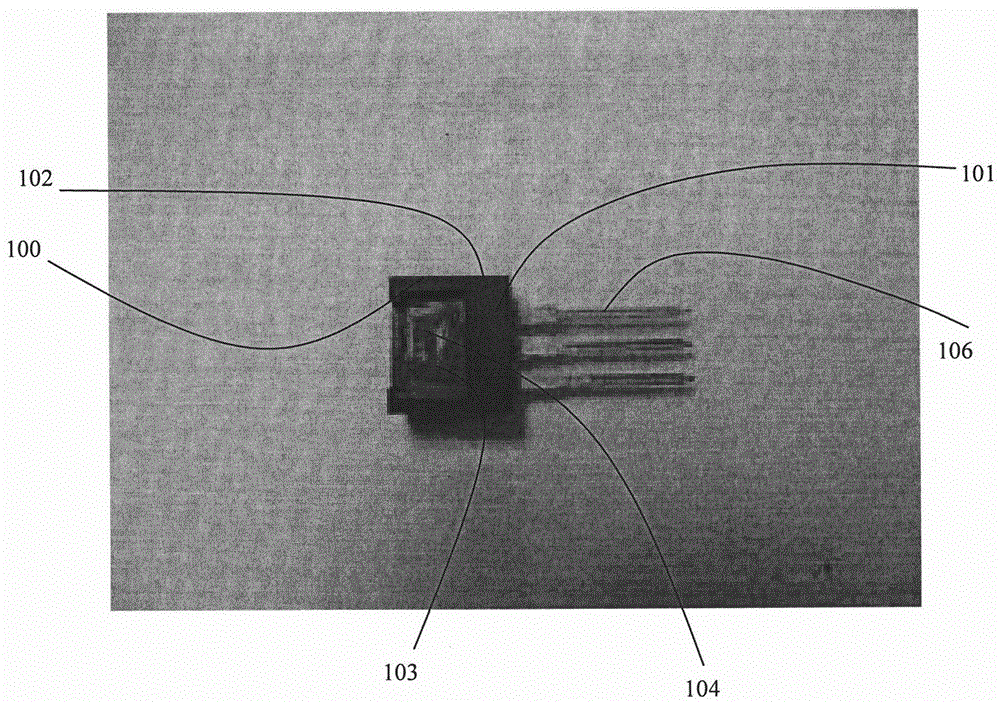

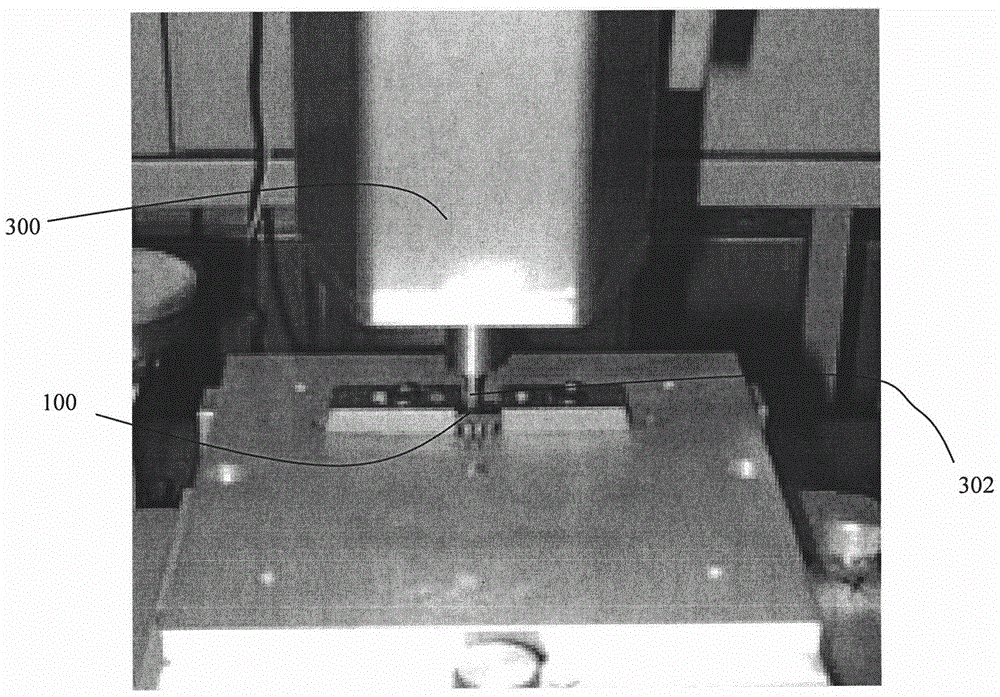

[0031] see figure 1 and figure 2 The semiconductor device 100 of the present invention has a main body 101 and three pins 106 extending from one side of the main body 101 . The main body 101 has a front (not numbered) and an opposite back 102 . The backside 102 has a copper layer, a silicon layer 104 and a chip stack 108 in sequence. The failure analysis method of the semiconductor device 100 of the present invention comprises the following steps:

[0032] S101 : removing the copper layer on the back surface 102 of the semiconductor device 100 .

[0033] The present invention uses 70% nitric acid solution 200 to etch away the copper layer on the back surface 102 of the main body 101 of the semiconductor device 100 . In order to prevent the pins 106 from being corroded by the nitric acid solution 200, the three pins 106 need to be well protected. In order to reduce the cost, in this step, the method of controlling the liquid level of the nitric acid solution 200 is adopte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com