System for automatically testing parameters of under-voltage trip unit and operation method for system

An automatic test system and undervoltage release technology, which is applied in circuit breaker testing and other directions, can solve the problems that it is difficult to adapt to the accuracy requirements of undervoltage releases and cannot detect the tripping force of undervoltage releases, and achieve Increase the variety, improve the detection speed, and the comprehensive effect of detection parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

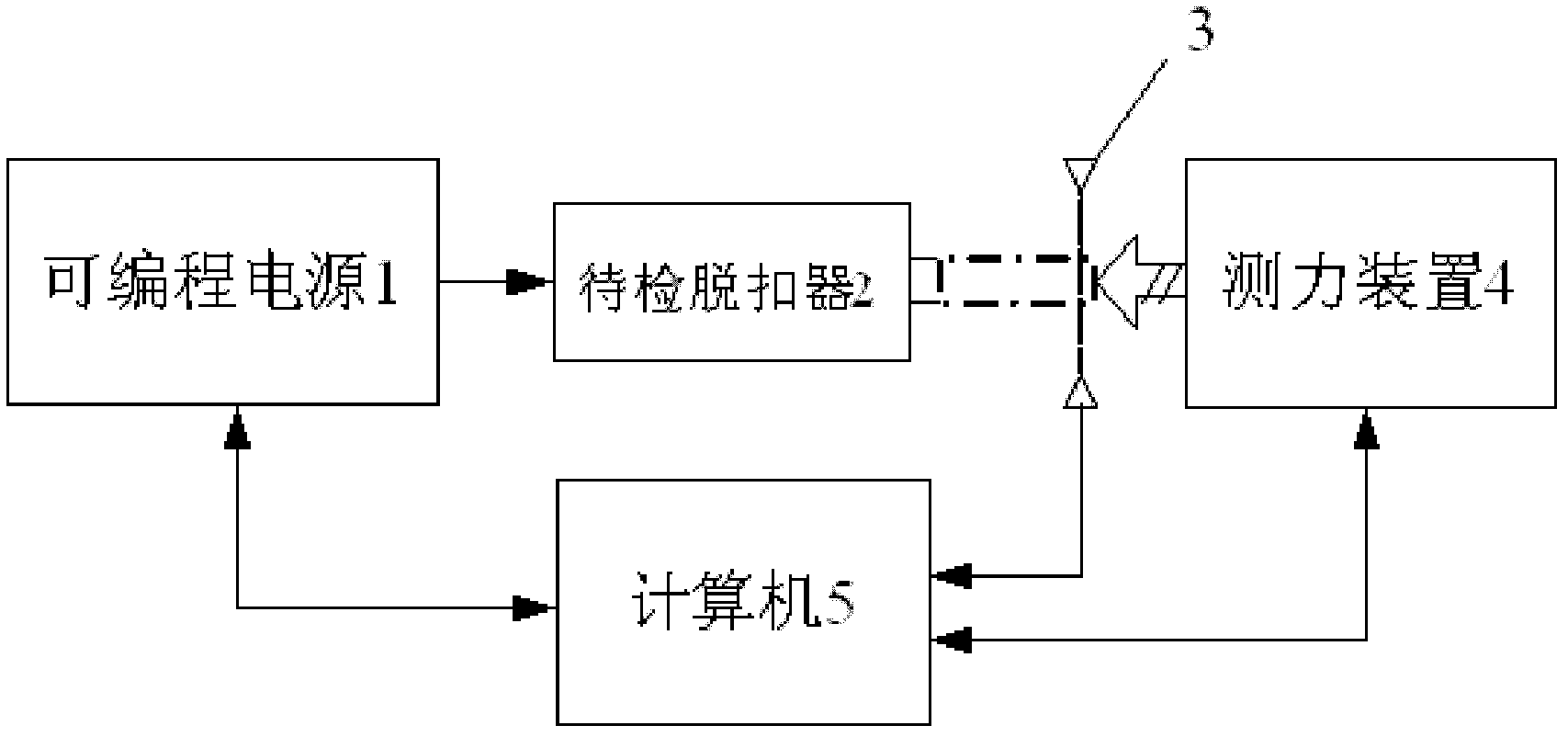

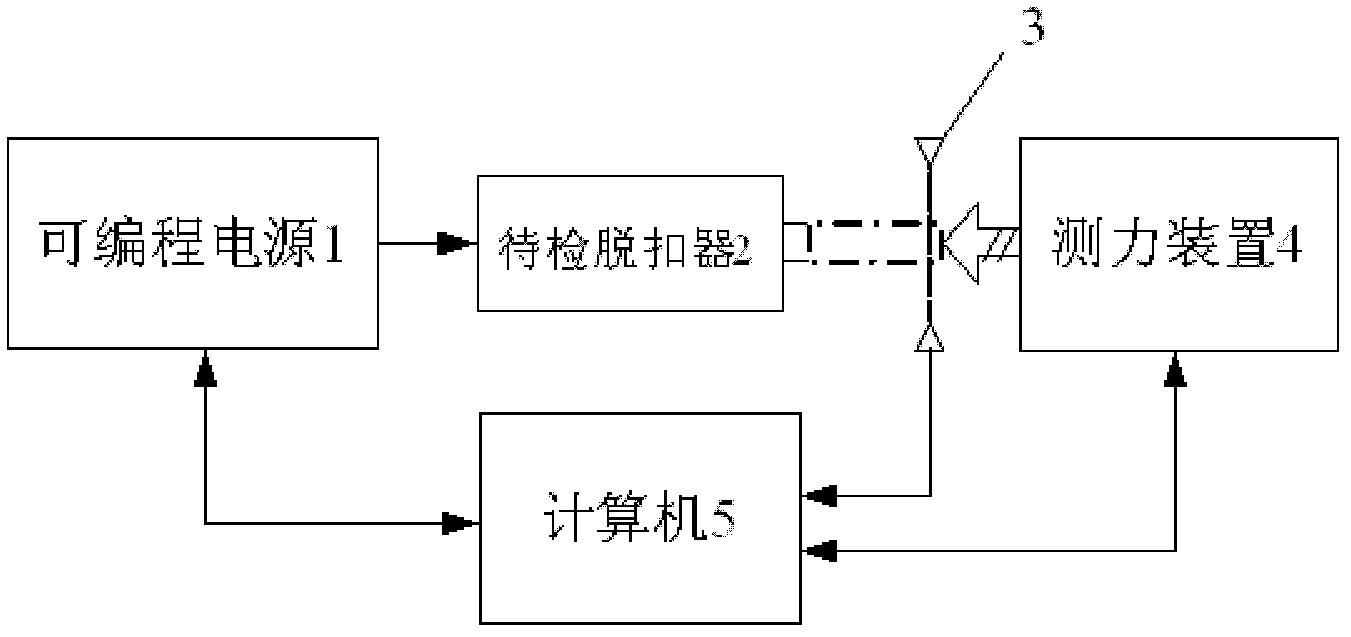

[0020] Such as figure 1 , the undervoltage release parameter automatic test system of this embodiment includes: the maximum output voltage is not less than the rated operating voltage U of the undervoltage release Double programmable power supply 1, force measuring device 4, and computer 5; the computer 5 is connected to the programmable power supply 1 for sending the control signal of the programmable power supply 1 and receiving the output voltage signal of the programmable power supply 1; The programmable power supply 1 is connected to the coil of an undervoltage release 2 to be tested; the detection signal output terminal of the force measuring device 4 for detecting the tripping force of the undervoltage release 2 to be tested is connected to the computer 5; the tripping force testing part of the force measuring device 4 is set opposite to the armature 2-1 of the release 2 to be tested. Among them, the programmable power supply can use the APS8000L linear programmable A...

Embodiment 2

[0025] The test method of the undervoltage release parameter automatic test system in the described embodiment 2 includes:

[0026] Step 1. Control the output voltage of the programmable power supply 1 from 30%* through the computer 5 U step to 90%* U, record the time point of this step as the first initial time point t1', and start timing; if the computer 5 detects that the armature 2-1 is engaged by the detection device 3, record the time point when the armature 2-1 is engaged is the first response time point t2', and the tripping response time Tr'=t2'-t1' is obtained; If it is within the standard response time range of the undervoltage release 2, it is judged that the undervoltage release 2 is unqualified;

[0027] Step 2, control the output voltage of the programmable power supply 1 from 80%* to 80% by the computer 5 U step down to 30%* U, record the time point of the downward step as the second initial time point t3', and start timing; if the detection device 3 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com