Array substrate and liquid crystal display

A liquid crystal display and array substrate technology, applied in the field of liquid crystal display, can solve problems such as display differences in corner areas, and achieve the effects of reducing display differences, improving display image quality, and improving aperture ratio and display contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

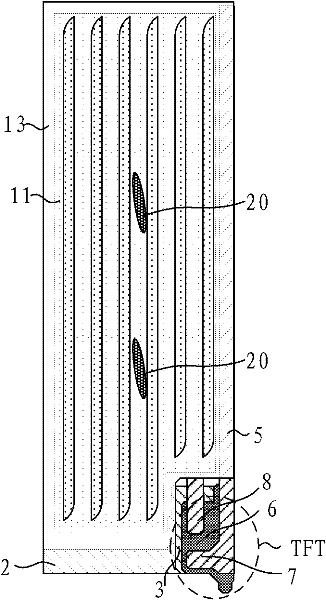

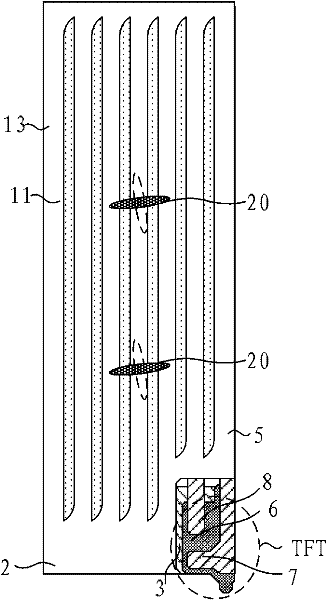

[0029] Figure 2A A schematic diagram of a partial top view structure of the array substrate provided in Embodiment 1 of the present invention, as shown in Figure 2A As shown, the array substrate includes a base substrate (not shown in the figure), and the pixel area of the base substrate is formed with data lines 5 and gate lines 2 that cross horizontally and vertically to form a plurality of pixel units, and each pixel The unit 30 includes a switching element TFT, a pixel electrode 11 and a common electrode 13, and the common electrode 13 in each pixel unit 30 has a slit 131, wherein:

[0030] The slits 131 of the common electrode 13 and / or the pixel electrode in each pixel unit 30 are zigzag-shaped, and the slits are parallel to each other, forming a slit area, Figure 2A In the above, the common electrode is above the pixel electrode, and the shape of the slit of the common electrode is zigzag as an example. If the common electrode is below the pixel electrode, the sha...

Embodiment 2

[0036] image 3 A schematic diagram of a partial top view structure of the array substrate provided in Embodiment 2 of the present invention, as shown in image 3 As shown, the array substrate includes a base substrate, the pixel area of the base substrate is formed with data lines 5 and gate lines 2 that cross horizontally and vertically to form a plurality of pixel units 30, and each pixel unit 30 includes a switch The element TFT, the pixel electrode 11 and the common electrode 13, the common electrode 13 in each pixel unit 30 has a slit 131, wherein: the shape of the slit 131 of the common electrode 13 in each pixel unit 30 is a zigzag shape, and each slit 131 are parallel to each other to form a slit area; the edge of the pixel electrode 11 pattern is parallel to the edge of the slit area; the gate line 2 and / or data line 5 is parallel to the edge of the adjacent pixel electrode pattern.

[0037] Further, the bending directions of the patterns of the pixel electrodes 1...

Embodiment 3

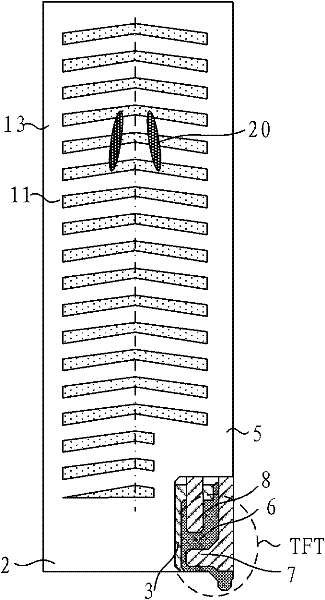

[0047] Figure 4 A schematic diagram of a partial top view structure of the array substrate provided in Embodiment 3 of the present invention, as shown in Figure 4 As shown, the array substrate includes a base substrate, the pixel area of the base substrate is formed with data lines 5 and gate lines 2 that cross horizontally and vertically to form a plurality of pixel units 30, and each pixel unit 30 includes a switch The element TFT, the pixel electrode 11 and the common electrode 13, the common electrode 13 in each pixel unit 30 has a slit 131, wherein: the shape of the slit 131 of the common electrode 13 in each pixel unit 30 is a zigzag shape, and each slit 131 are parallel to each other to form a slit area; the edge of the pixel electrode 11 pattern is parallel to the edge of the slit area; the gate line 2 and / or data line 5 is parallel to the edge of the adjacent pixel electrode pattern.

[0048] Further, the pixel units 30 are arranged in a matrix.

[0049] In addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com