Finite-element analysis-based method for designing profile of autoclave molding fixture of composite material member

A composite material component and autoclave forming technology, which is applied in computing, special data processing applications, instruments, etc., can solve the problems of high development cost, long cycle, and unguaranteed component profile accuracy, and improve design quality. and efficiency, ensure accuracy, and eliminate the effect of low component accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

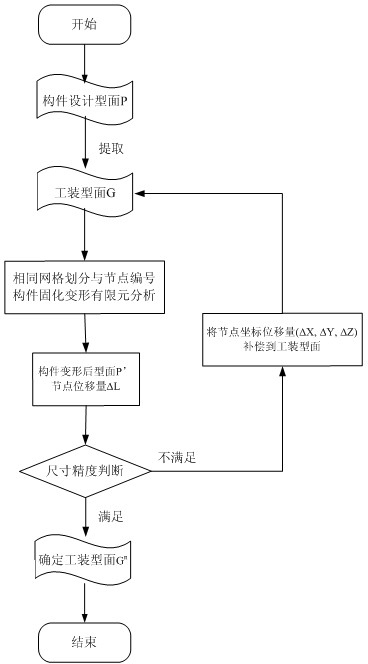

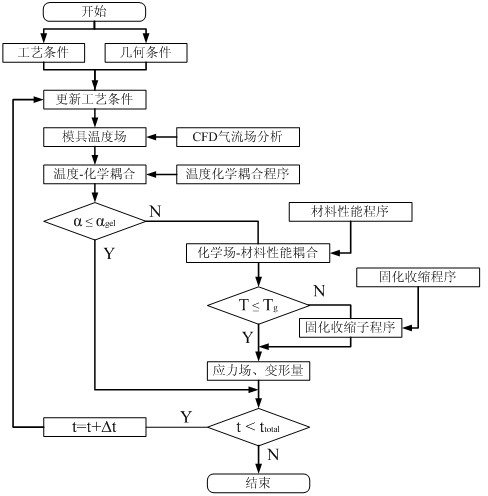

[0020] A design method of autoclave forming tooling surface based on finite element analysis, which is suitable for the preconditions of known curing process system, component geometry and material parameters, tooling support structure and material parameters of autoclave forming composite components . Below to Image 6 The cylindrical composite material component shown is taken as an example to illustrate the implementation process of the tooling surface compensation design method. The tooling is cylindrical, the thickness d is 12mm, the component thickness is 5mm, and the inner radius is 200mm. The specific implementation steps are as follows:

[0021] (1) The initial surface G of the tooling is directly extracted from the component design surface P, and the tooling structure is designed.

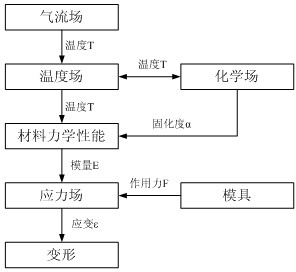

[0022] (2) Divide the same grid for the component and tooling surface in step (1), and realize the solidification of the component according to the multi-field coupling relationship and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com