Real-time bus working state monitoring method and intelligent bus system

A working state, busbar system technology, applied in the field of electric power, can solve the problems of loose contact, poor contact, busbar without detection and alarm functions, abnormal overheating, etc., to avoid untimely data transmission, avoid real-time transmission of monitoring data, guarantee The effect of real-time transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

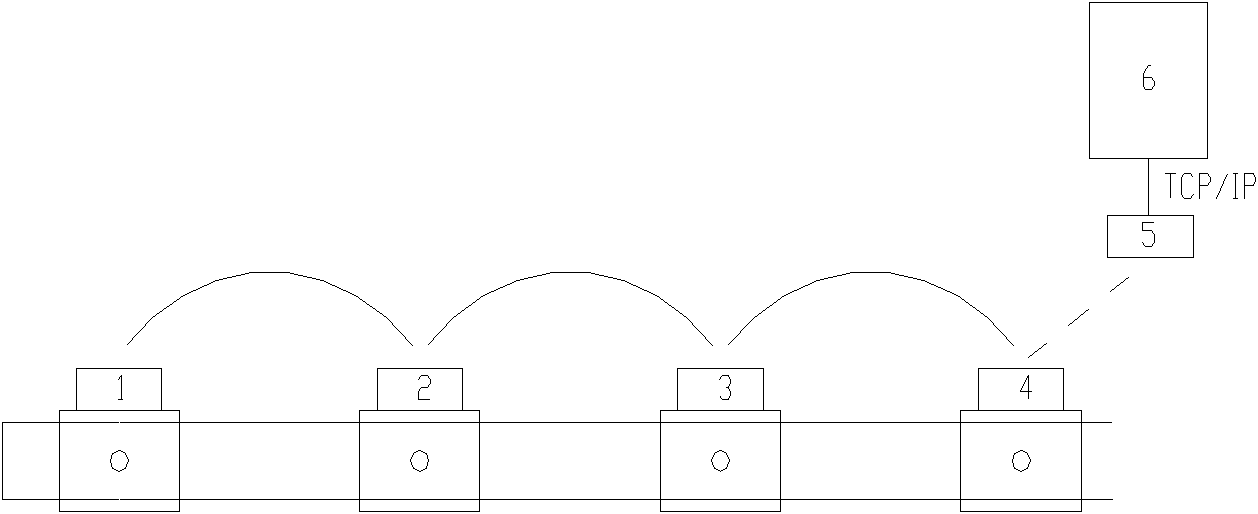

[0126] Embodiment 1 provides a method for real-time monitoring of bus working status, including:

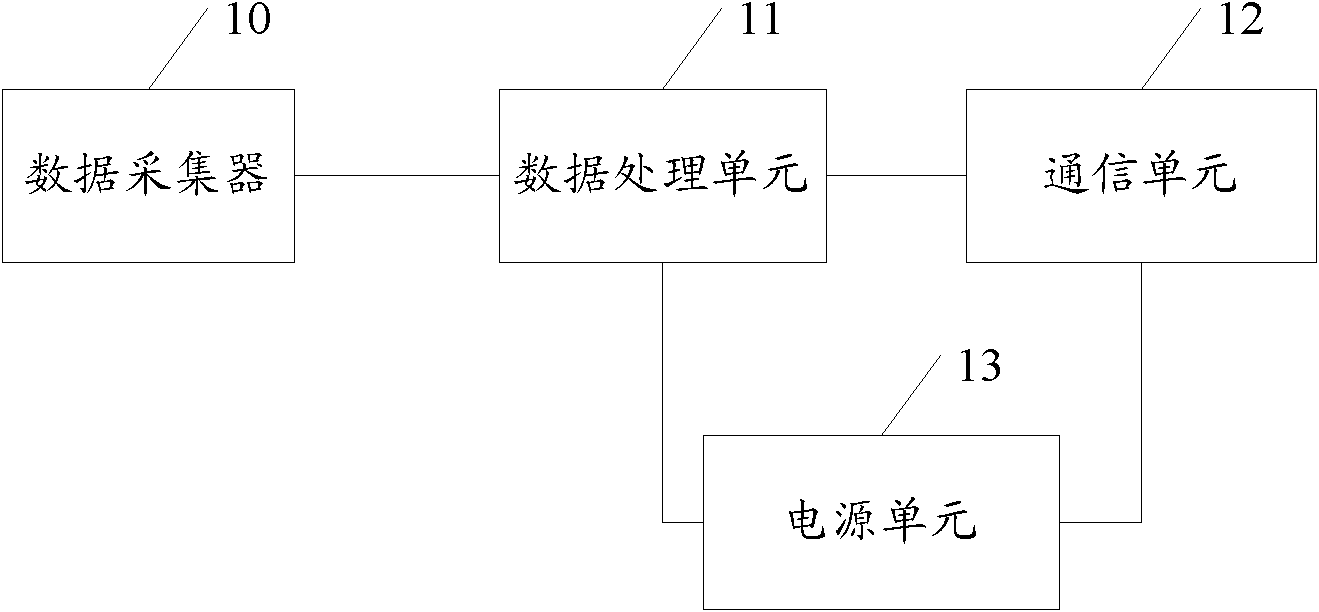

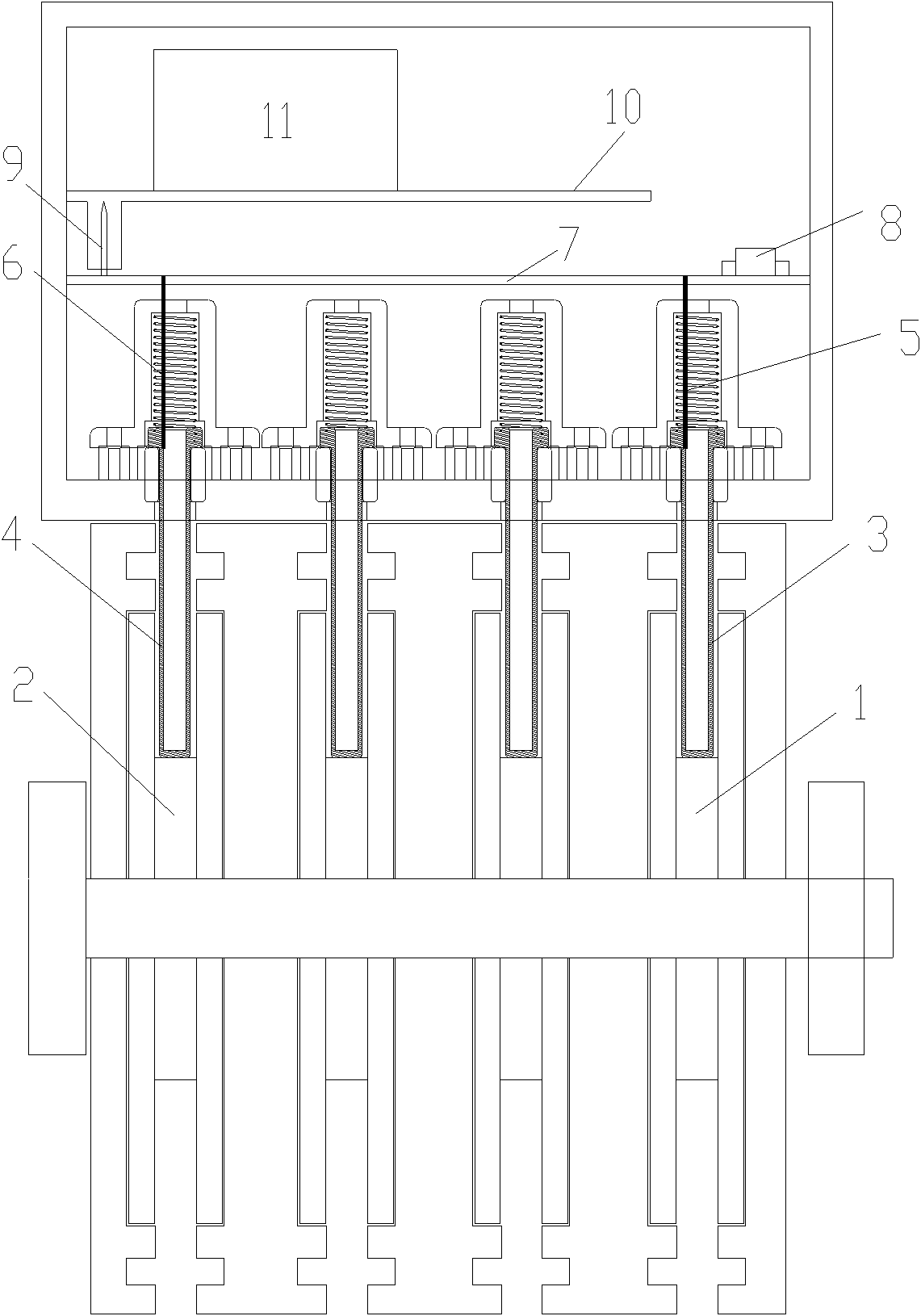

[0127] Step 100, a plurality of intelligent busbar joint units arranged on each busbar joint collect the working state parameters of each busbar respectively, and select the nearest routing path to transmit the collected busbar working state parameters to the intelligent control box; State parameters include busbar temperature, current, voltage and other parameters;

[0128] Step 101, the intelligent control box polls the multiple intelligent bus joint units, and uses single or multiple channels to receive the working status of the busbar from the multiple bus joints transmitted by wireless ad hoc network technology at the same time parameters, and send the received busbar working status parameters to the management device after protocol conversion;

[0129] Step 102, the management device monitors, manages and controls the working state of the bus bar according to the working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com