Three-level inverter narrow pulse elimination and midpoint voltage control method and device

A three-level inverter, narrow pulse technology, applied in the field of frequency converters, can solve the problems of easily damaged power switch tubes, system collapse, difficult control of mid-point voltage, etc. The effect of narrow pulses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

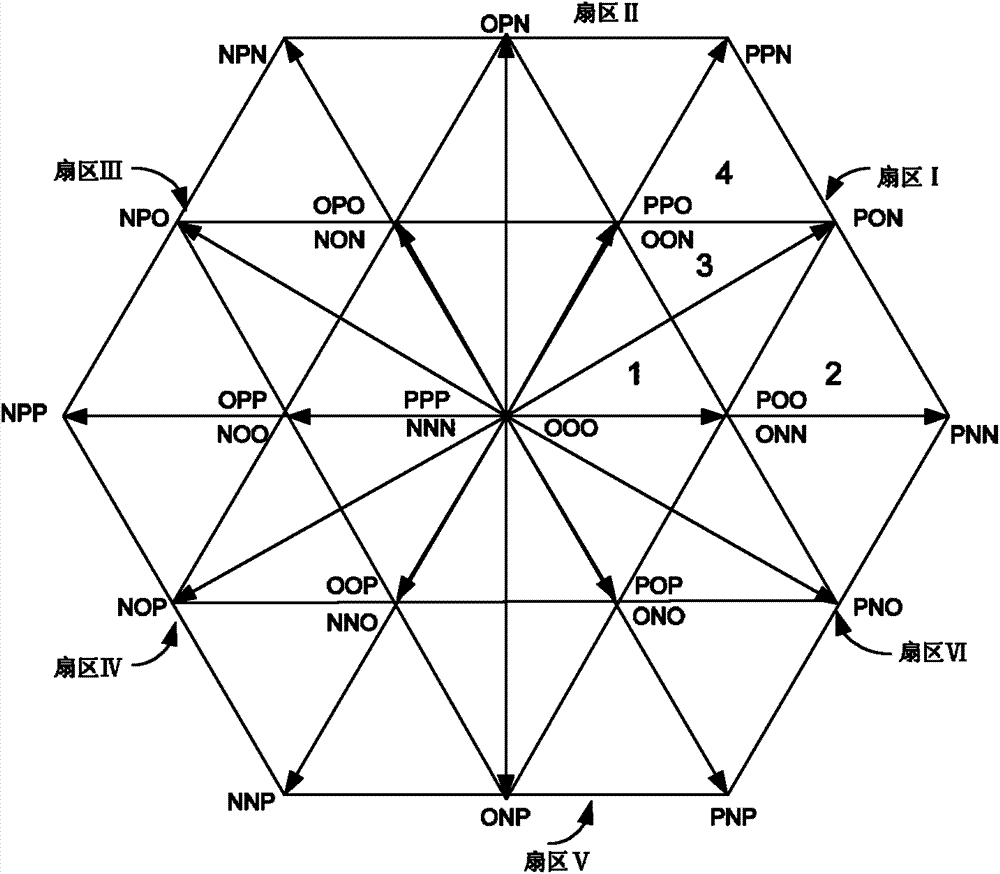

[0042] Three-level inverter, when the output voltage is positive, it is marked as P, when the output voltage is negative, it is marked as N, and when the output voltage is 0, it is marked as O. In this way, each phase can output three levels, three There are 27 output combinations on the phase output line, that is, 27 space vectors. The distribution diagram of these 27 space vectors is as follows: figure 2As shown, 27 space vectors are distributed in 6 sectors in total. The 6 sectors are regular hexagons in the figure, and each sector is a regular triangle, where PPP, NNN, and OOO are zero vectors, and PNN, PPN, NPN, NPP, NNP, PNP are large vectors, PON, OPN, NPO, NOP, ONP, PNO are medium vectors, POO, ONN, PPO, OON, OPO, NON, OPP, NOO, OOP, NNO, POP, ONO is a small vector, and the output voltage of the three-level inverter is close to zero under low modulation coefficients. Therefore, it is obtained by combining the zero vector and the small vector.

[0043] In order to ena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com