Method and device for recycling and reusing heat energy of lighting facilities

A technology for lighting facilities and heat recovery, applied in lighting devices, cooling/heating devices for lighting devices, lighting and heating equipment, etc., can solve problems such as mercury pollution, poor color rendering, and insufficient luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

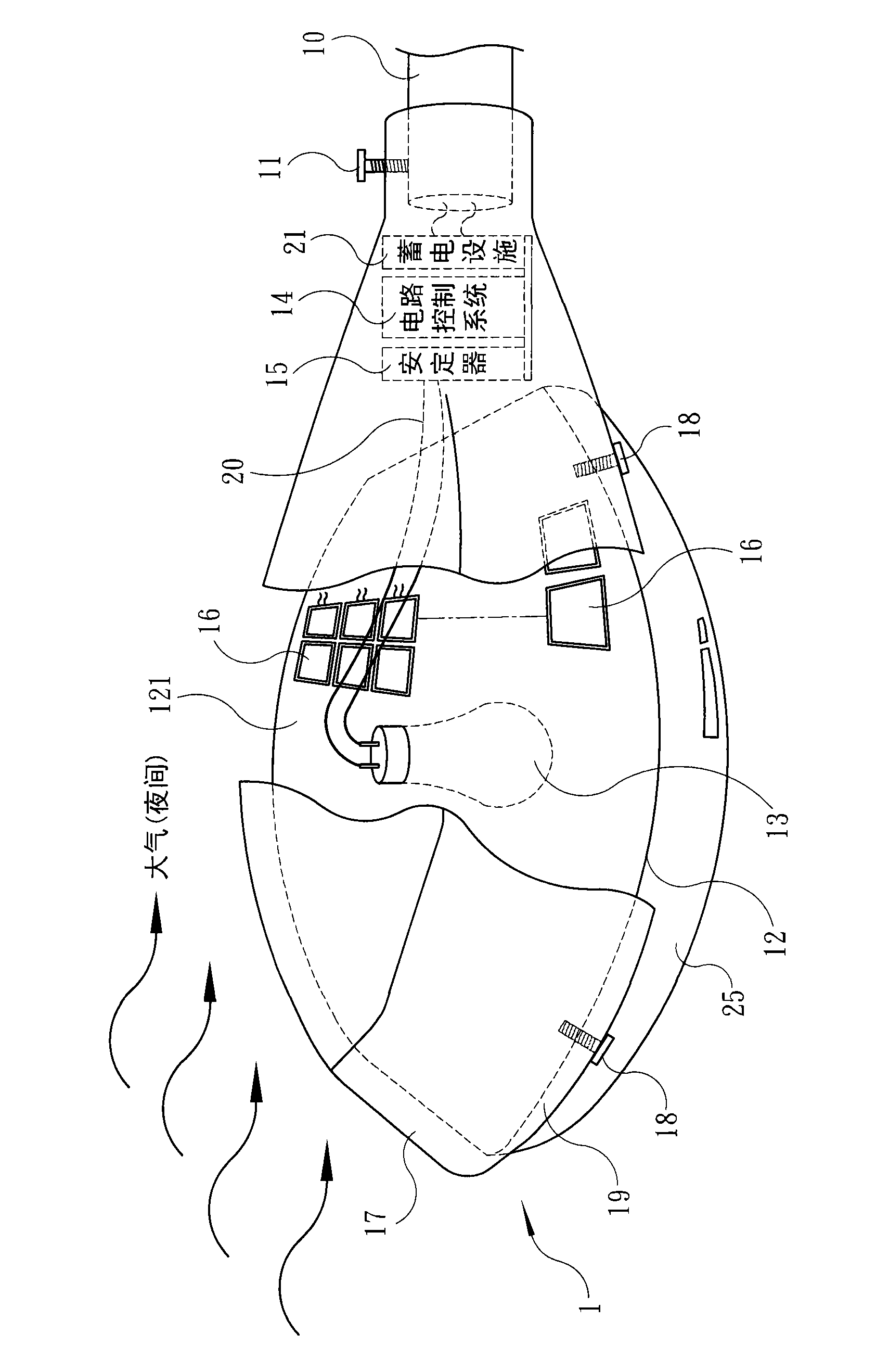

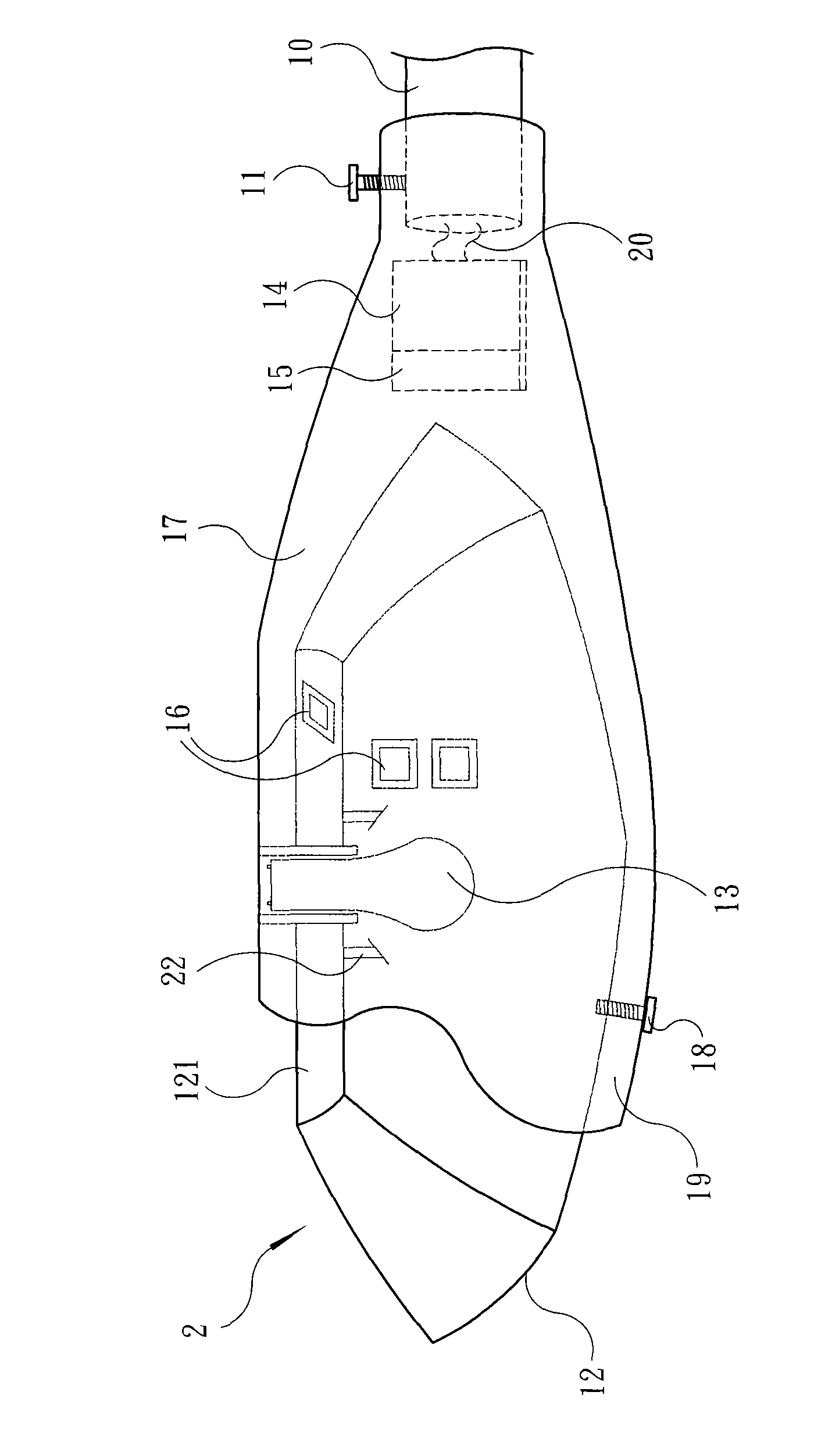

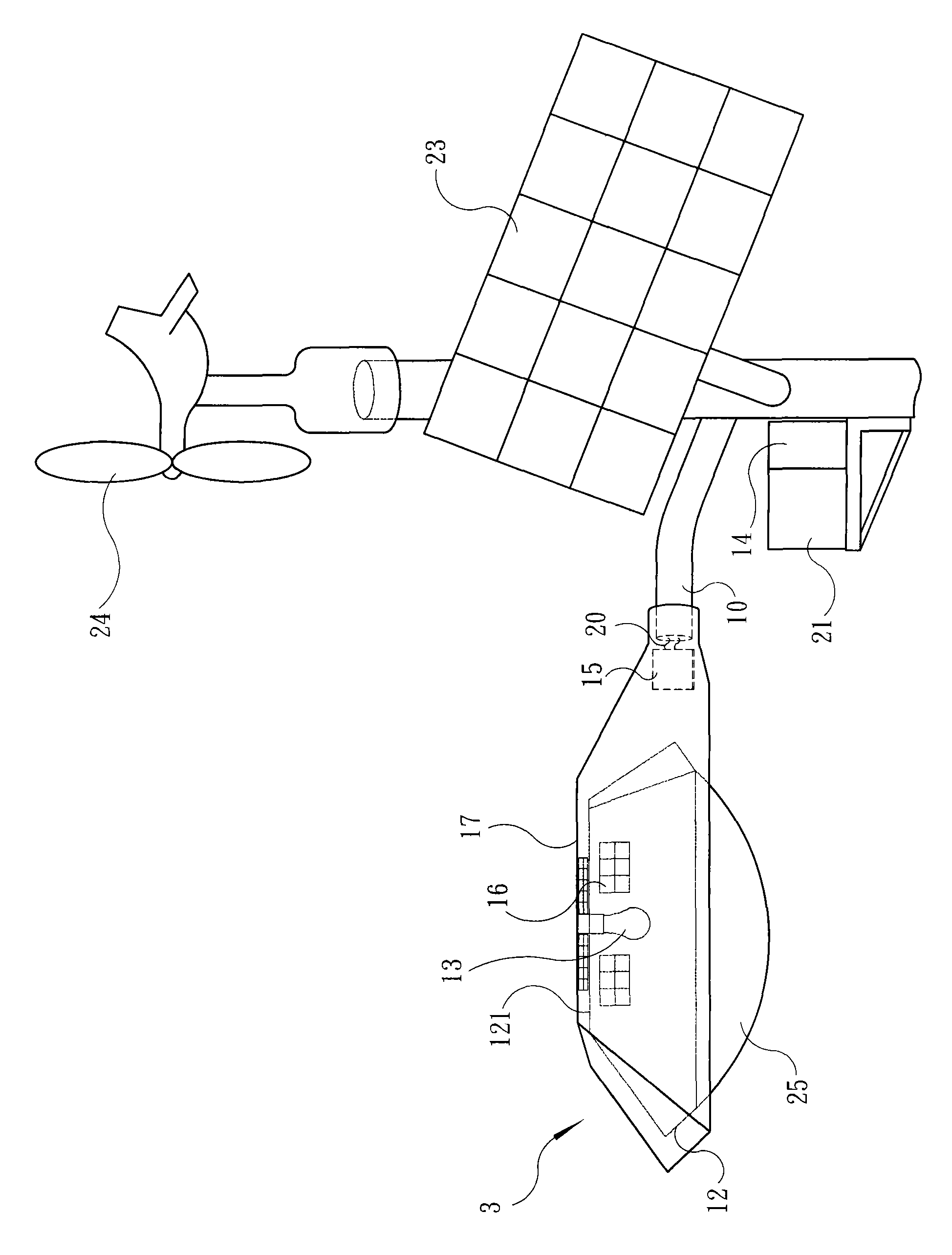

[0072] see figure 1 , the present embodiment is illustrated with a general street lamp. At the end of a light pole 10, a reflector 12, a transparent shield 25, a light source 13, a circuit control system 14, a stabilizer 15, and a thermoelectric chip module 16 arranged on the outer surface 121 of the reflector are installed with fastening screws 11. The light fixture lamp shell 17 of spare parts such as is set firmly. The light source 13 of the present invention can be various products, such as the light bulb 13 shown in this embodiment. Wherein the lamp housing 17 and the reflector 12 are fastened together by fastening bolts 18, and a heat insulating material 19 is placed in the middle spacer to avoid the effect of heat conduction, so that the two can maintain a cold end and a hot end respectively, forming a temperature dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com