Non-destructive welding device of micro-PCB (printed circuit board) device

A welding device and miniature technology, which is applied in the direction of assembling printed circuits with electric components, can solve the problem of inability to realize the repair welding of micro-PCB components that are not resistant to high temperature, and achieve the requirements of improving operation efficiency and process implementation accuracy and reducing operation skills , Solve the effect of manual patching or dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

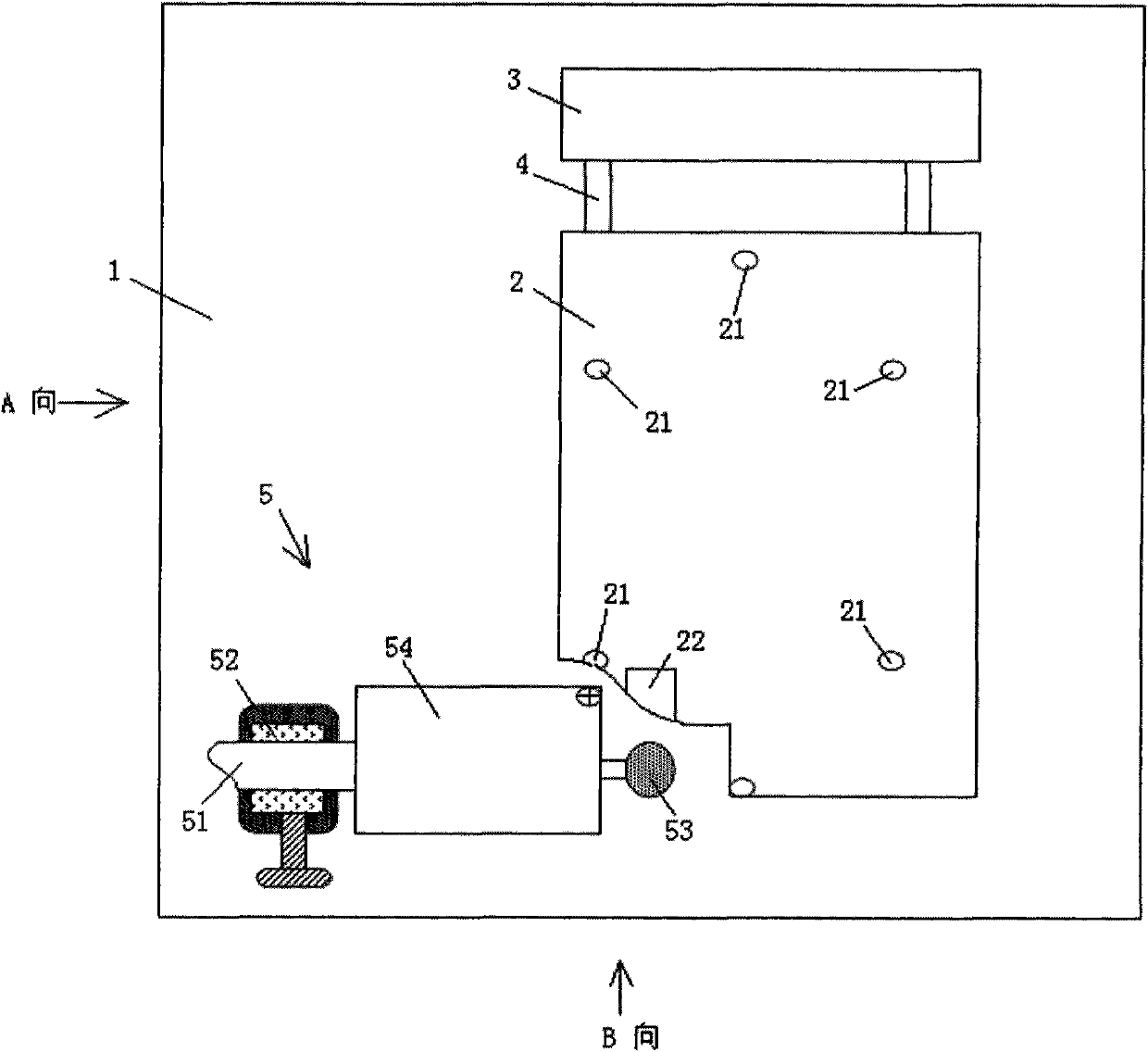

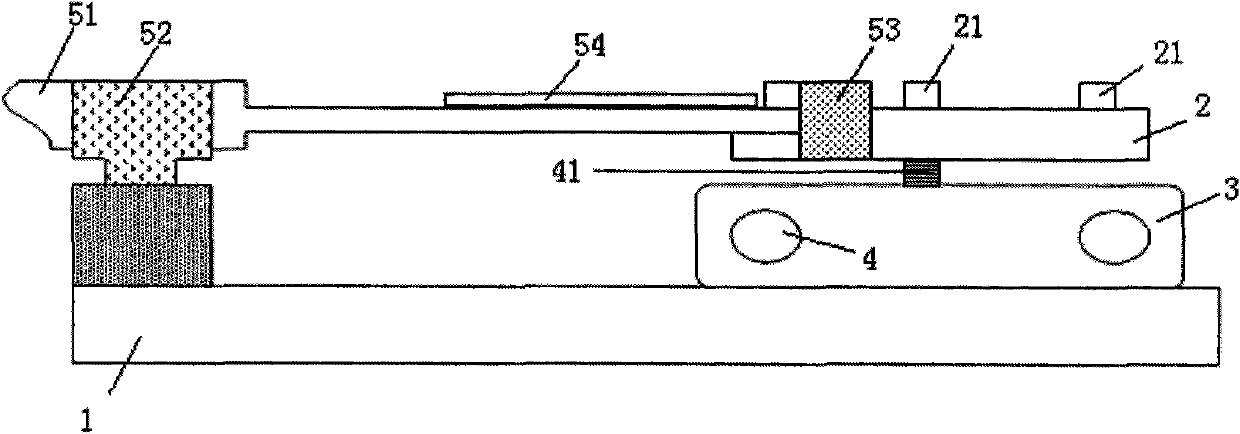

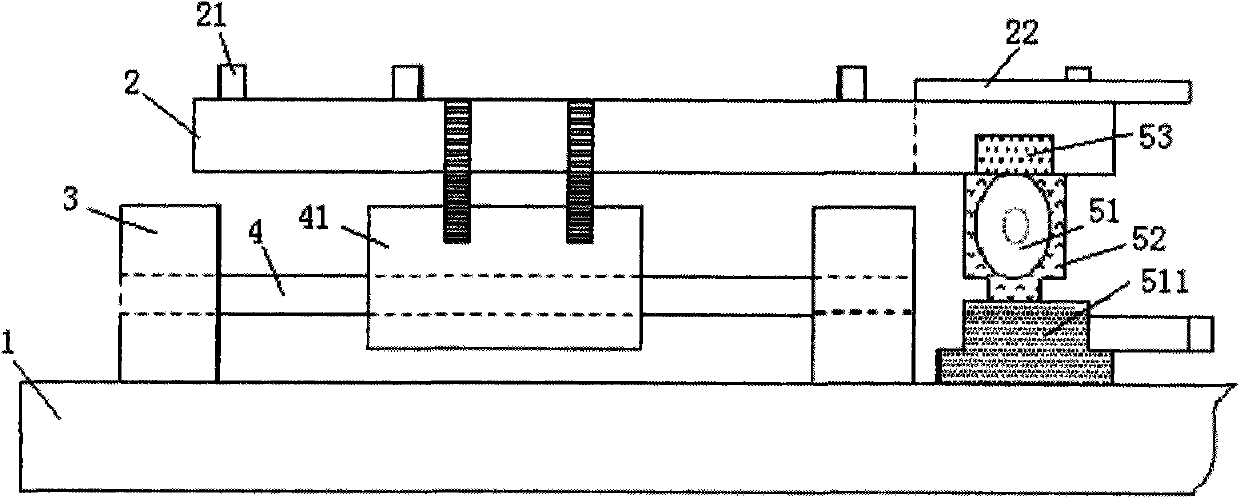

[0032] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0033] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of non-destructive soldering tool for partial parts of micro PCB, comprising a bottom plate 1, one movable on the bottom plate 1, and a transfer platform 2 for placing and moving the micro PCB; one fixed on one side of the bottom plate 1 The heating device 5. The heating device 5 is close to one side of the transfer platform 2 and is located below the plane where the transfer platform 2 is located. In this way, when the micro PCB moves above the heating device 5, the bottom of the micro PCB can be heated by the heating device 5, so as to complete the non-destructive welding of the local components of the micro PCB.

[0034] Preferably, the heating device 5 of the present invention may include: a heater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com