Pipe cutting machine

A technology of pipe cutting machine and cutting machine, applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of operator burns, larger and rougher blade diameter, etc., to achieve firm maintenance and low cutting noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

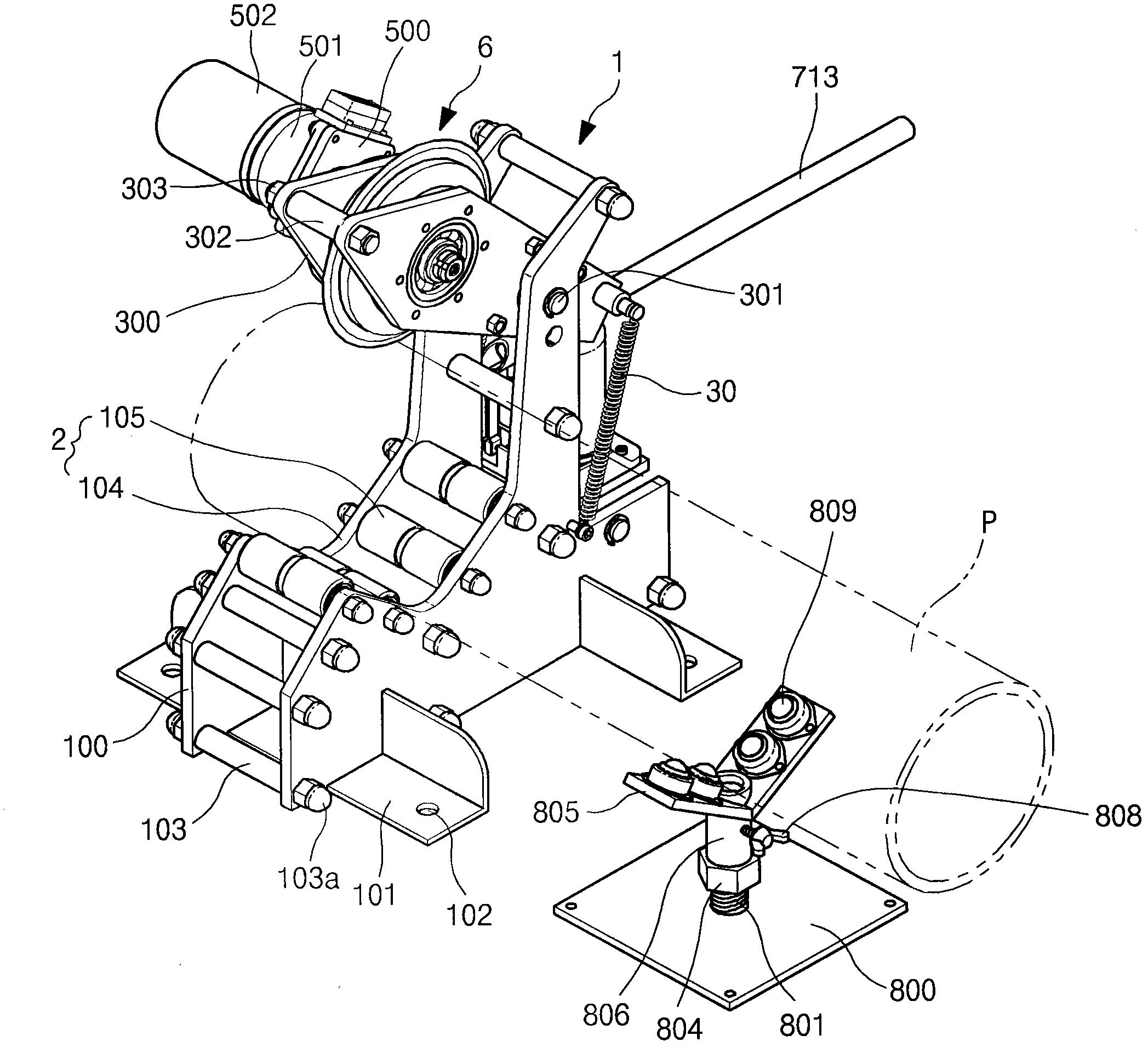

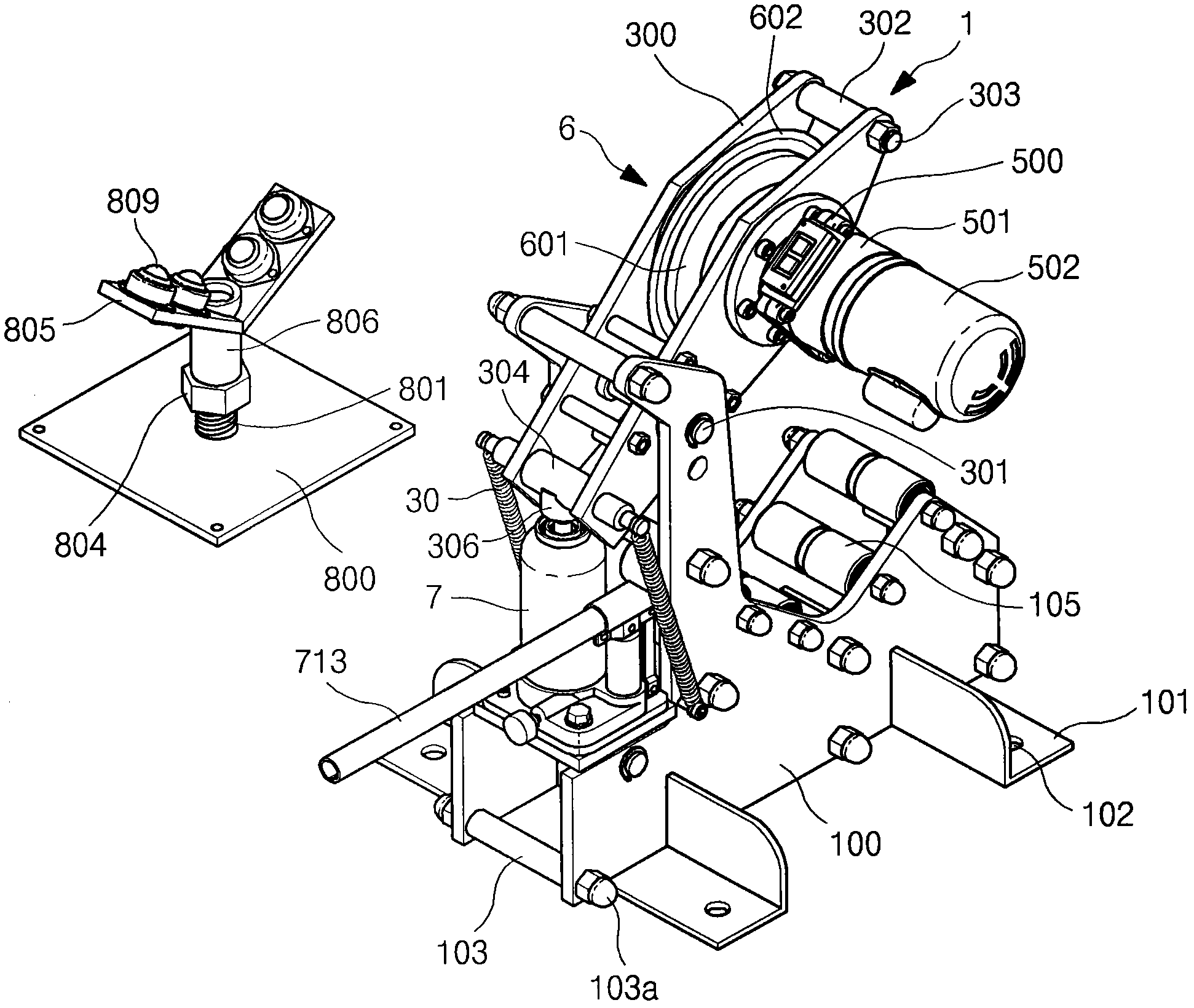

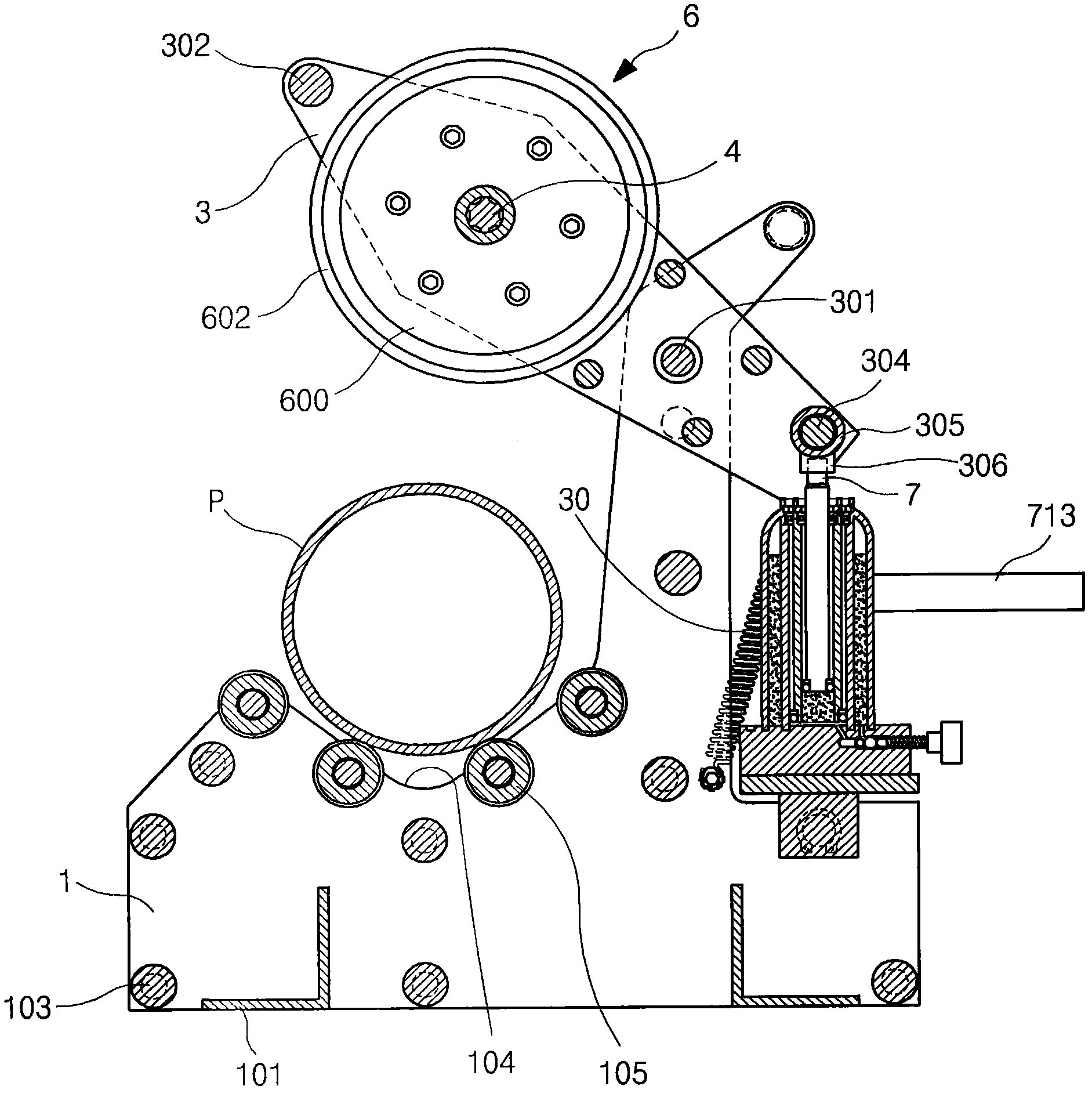

[0051] Hereinafter, a pipe cutting machine according to the present invention will be described with reference to the accompanying drawings. First, the same symbols are assigned to the same constituent elements or components in the drawings. When describing the present invention, in order to clarify the gist of the present invention, specific descriptions of related known functions or configurations are omitted.

[0052] figure 1 is an overall perspective view showing the present invention, figure 2 It is a perspective view showing the back side, image 3 It is a vertical side view.

[0053] and, Figure 4 yes image 3 The action state diagram of Figure 5 is an exploded perspective view of the sub-chassis according to the present invention, Figure 6 is a sectional view illustrating the cutter portion of the present invention, Figure 7 yes Figure 6 exploded perspective view.

[0054] Figure 8 is a sectional view of the hydraulic jack part of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com