Special-shaped streaming trickle irrigation device

A sprinkler and special-shaped technology, which is applied in watering devices, horticulture, botanical equipment and methods, etc., can solve the problems of serialization degree to be improved, fewer product varieties and specifications, and deposition of impurities in water, etc., to achieve good outflow stability and anti-clogging ability, large average section size, and strong water flow turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

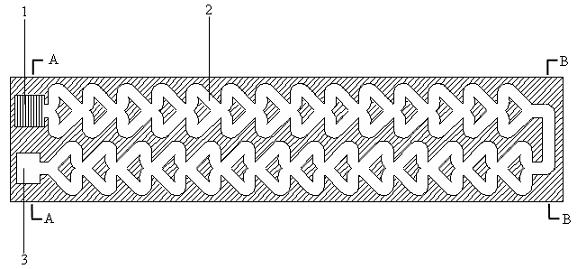

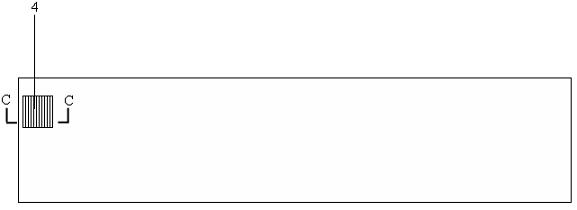

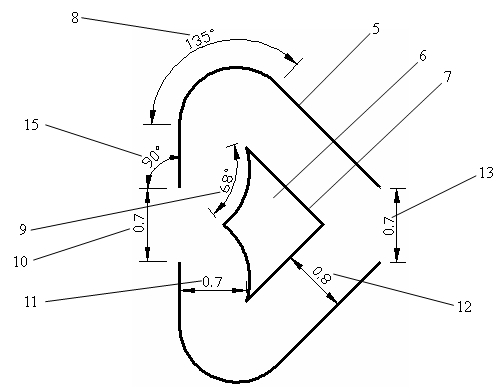

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the special-shaped bypass drip irrigation emitter is composed of water inlet tank 1, flow channel, water outlet tank 3, and filter window 4. The filter window 4 is set at the bottom of the water inlet tank 1, and the water inlet tank 1 is connected to the flow channel. The flow channel is imported by a flow channel unit. 10 is connected to the outlet 13 of another flow channel unit, and several flow channel units 2 are connected in sequence. In order to reduce the total length of the flow channel, the flow channels are arranged in two rows, and finally connected to the outlet tank 3, and the outlet tank 3 and the water inlet tank 1 are pouring water at the same end point of the device; the flow channel unit 2 is composed of the flow channel unit outer wall 5, the special-shaped surrounding fluid 6, the flow channel unit inlet 10, and the flow channel unit outlet 13. The plane projection...

Embodiment 2

[0030] refer to Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 , the special-shaped bypass drip irrigation emitter is composed of water inlet tank 1, flow channel, water outlet tank 3, and filter window 4. The filter window 4 is set at the bottom of the water inlet tank 1, and the water inlet tank 1 is connected to the flow channel. The flow channel is imported by a flow channel unit. 10 is connected to the outlet 13 of another flow channel unit, and several flow channel units 2 are connected in turn to form, the flow channels are arranged in a row in a line, and finally connected to the outlet tank, the outlet tank and the water inlet tank are at two different endpoints of the emitter; The flow channel unit 2 is composed of the flow channel unit outer wall 5, the special-shaped surrounding fluid 6, the flow channel unit inlet 10, and the flow channel unit outlet 13. The plane projection of the flow channel unit outer wall 5 is a geometric figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com