Preparation method of buried micropore ceramic root-irrigation emitter

A microporous ceramic, buried technology, which is applied to root waterers, botanical equipment and methods, ceramic material production, etc. , The effect of saving one-time investment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The applicant found in the research that the soil particles in the clay are composed of: clay: 5.46%, silt: 29.26%, sand: 65.28%; Stone, Vermiculite, Illite, Allophane.

[0032] The chemical components contained in the slag are mainly silicon dioxide, aluminum oxide, ferric oxide, calcium oxide, and magnesium oxide.

[0033] The applicant uses clay and slag as raw materials to develop a new buried microporous ceramic root irrigation sprinkler. The buried microporous ceramic root irrigation sprinkler is formed by sintering clay and slag, and the micropores serve as energy dissipation The method improves the energy dissipation method used by various emitters before. The prepared microporous ceramic root irrigation emitter has a good filtering effect, can effectively prevent physical blockage, and improve the service life of the emitter. The development of micro-irrigation emitters provides a new way of thinking.

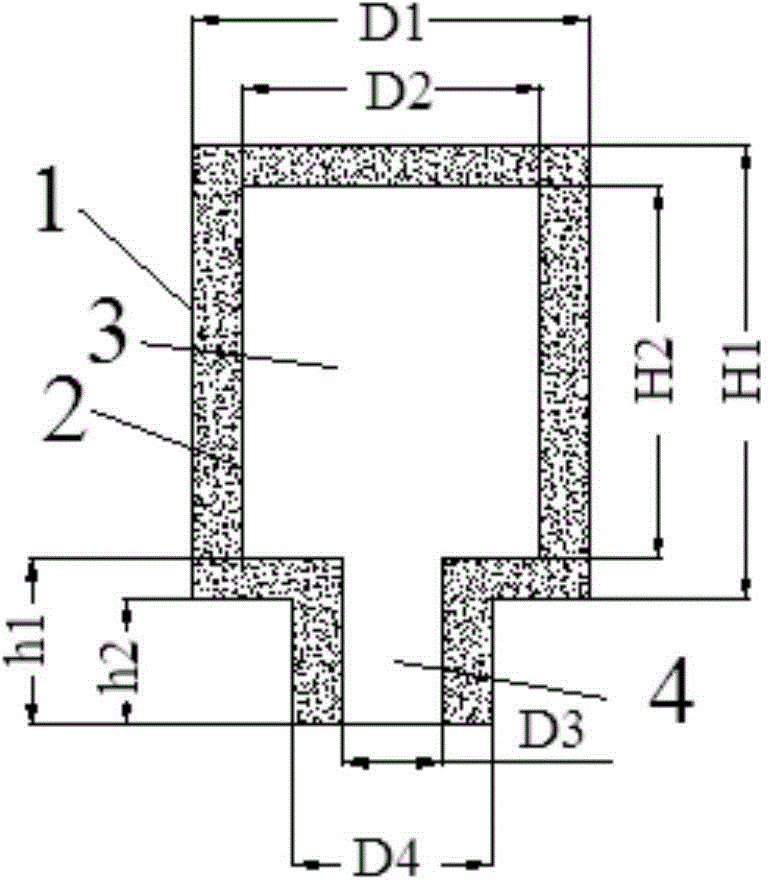

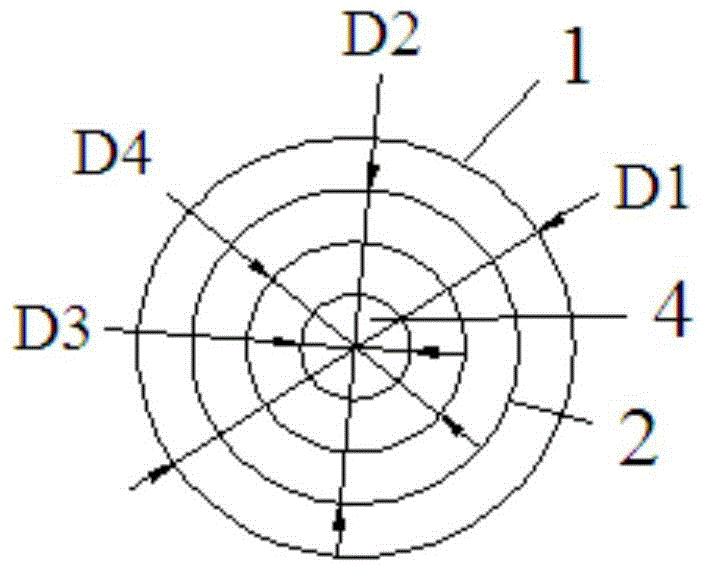

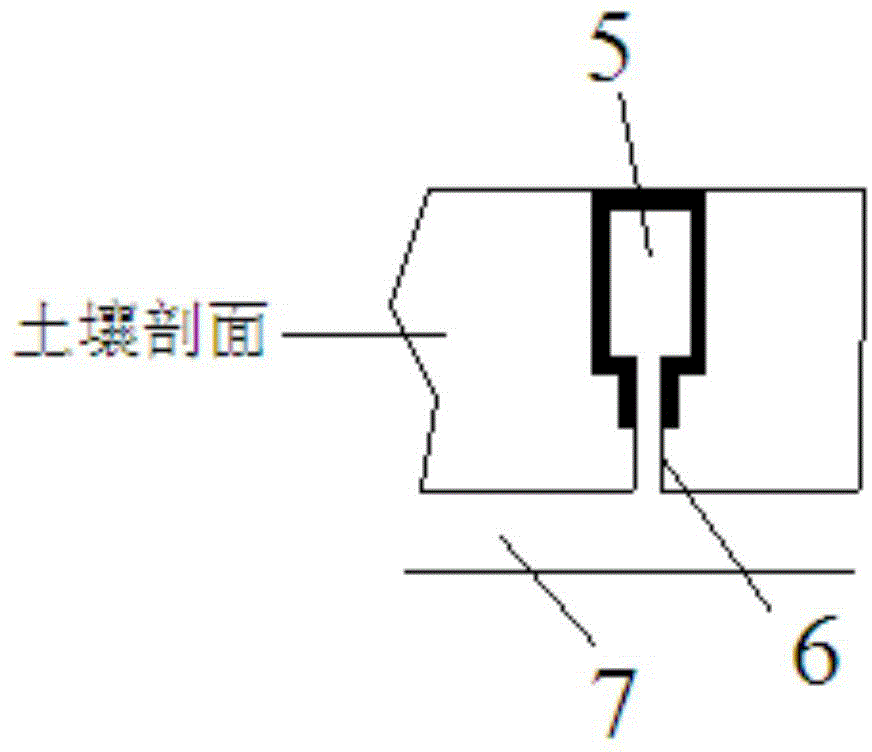

[0034] see figure 1 and figure 2 , the present embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com