Overweight force field mass transfer and reaction device without gas phases

A technology of hypergravity field and reaction device, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as unsatisfactory efficiency, and achieve simple structure and small size. , the effect of effective and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

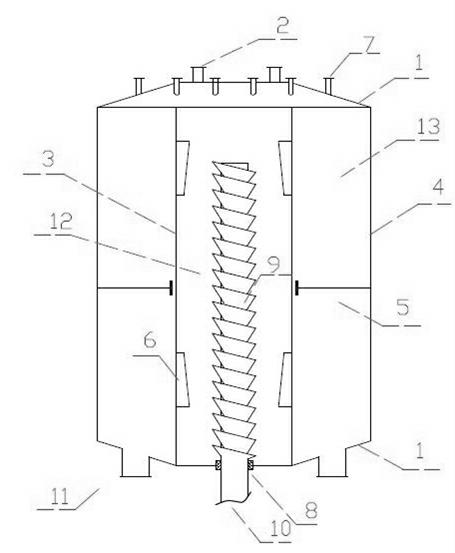

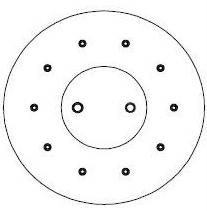

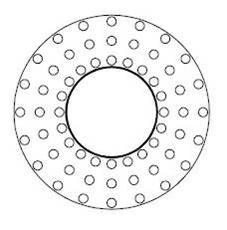

[0018] as attached figure 1 The shown mass transfer and reaction device in a supergravity field without gas phase participation is a double-chamber cylindrical device composed of a housing 4 and an inner cylinder 3. Inside the inner cylinder 3 is an inner chamber 12, and the housing 4 and the inner cylinder Between the cylinders 3 is the outer chamber 13; the inner cylinder 3 is a porous cylinder with a fixed aperture, and the inner chamber 12 is topped with a circular top cover, and there are two top inlets 2 for liquid or liquid-solid mixture in the center of the top cover. The inlet 2 at the top of the mixture is symmetrically distributed on both sides of the center of the top of the outer chamber; the bottom of the inner chamber 12 has a circular bottom plate, the center of the bottom plate is equipped with a rotor 9, and eight vortex baffles 6 are vertically installed on the wall of the inner chamber 12; the top of the outer chamber 13 There are slope-shaped cover plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com