Method for determining closed-loop shape control cycle of cold-rolled strip steel plate

A technology of closed-loop control and steel plate shape, which is applied in the direction of contour control, etc., can solve the problem of poor control effect of strip steel plate shape at export, and achieve the effect of increasing market competitiveness, meeting real-time requirements, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

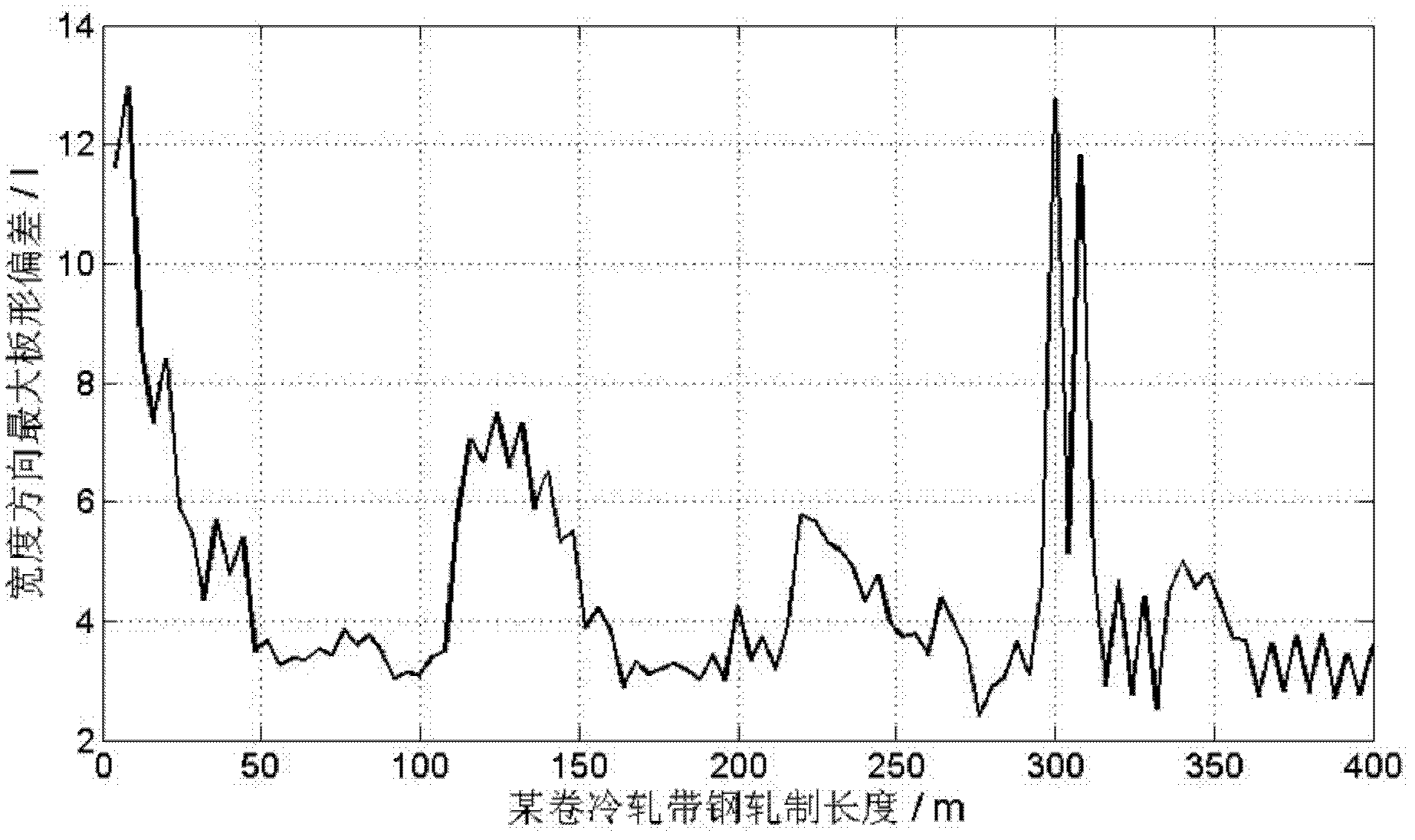

Examples

Embodiment Construction

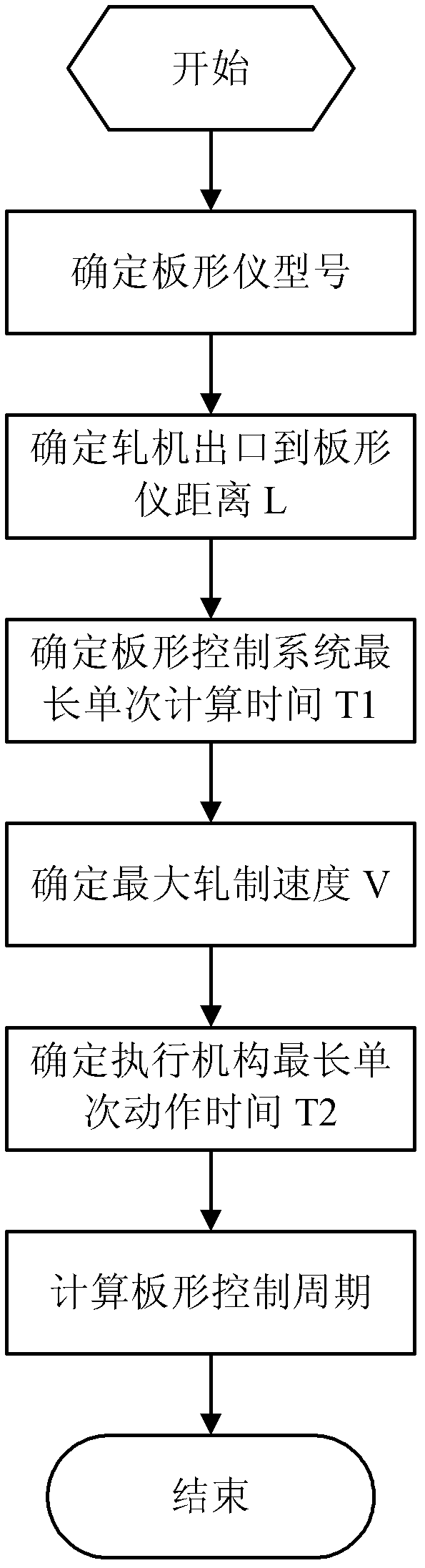

[0032] The method for determining the closed-loop control cycle of cold-rolled strip steel plate shape provided by the invention, its steps include:

[0033] (1) Determine the type of shape meter configured at the exit of the rolling mill:

[0034] The shape meter model determines two key variables in the determination method of the cold-rolled strip shape control period: the radius R (unit: mm) of the shape roller and the number of times n ( The unit is times / revolution).

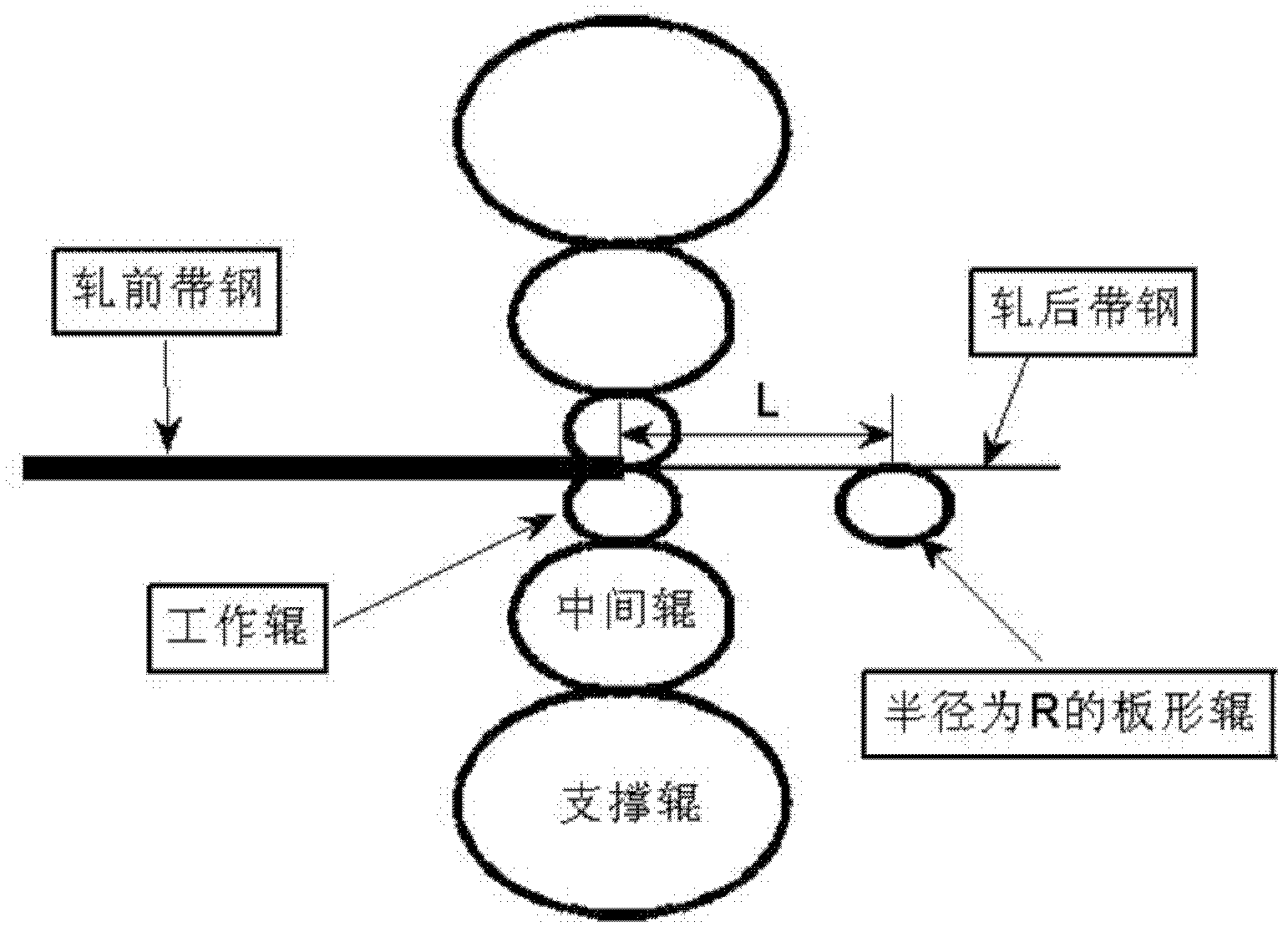

[0035] (2) Determine the distance L (unit: mm) from the exit of the rolling mill to the shape meter:

[0036] The distance from the exit of the rolling mill to the shape meter directly affects the transfer time of the strip from the exit of the rolling mill to the shape meter. The larger L is, the greater the time lag of the system is. In the design of rolling mill equipment, the L value should be as small as possible on the basis of considering the limitations of equipment installation and other technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com