Multifunctional sand box for casting

A multi-functional, sandbox technology, applied in the field of mechanical casting, can solve the problems of low utilization rate of sandbox, high pressure of molten iron, etc., and achieve the effect of avoiding repeated investment, lowering entry barriers, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

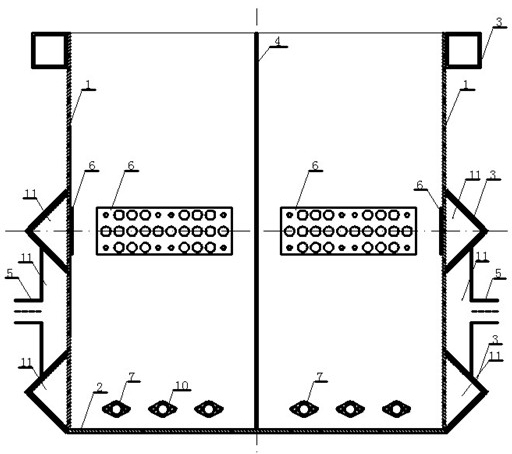

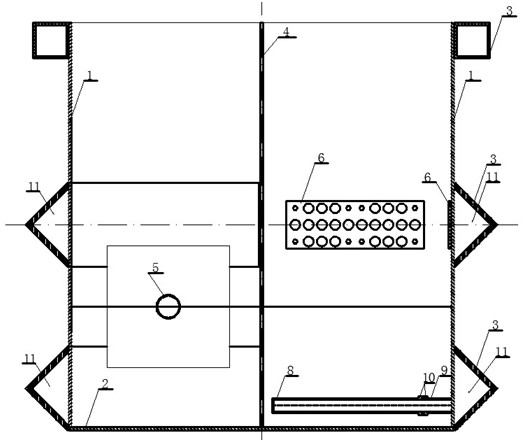

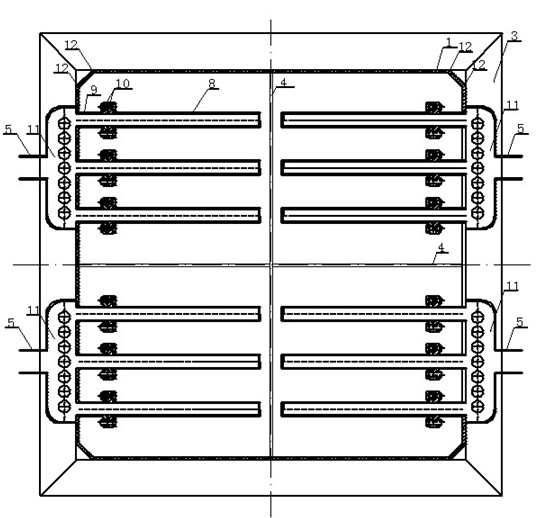

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0014] exist figure 1 , figure 2 and image 3 Among them, this multifunctional sand box for casting includes a box wall 1 and a box bottom 2 around it. Steel profiles 3 for reinforcement are installed around the box wall 1. There are two vertical partition boards 4 in the sand box. The case is divided into four small sand boxes which are not connected with each other, and each small sand box has an independent vacuuming interface 5 on the side and the bottom surface.

[0015] When the side wall of the small sand box overlaps with the box wall 1, a sand separation and ventilation plate 6 is installed on the side wall of the overlapping part, and a screen is installed between the sand separation and ventilation plate 6 and the box wall 1, and the sand separation and ventilation plate 6 The air passage 11 outside the box wall communicates with the vacuuming interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com