Spindle box for extra-heavy numerical control horizontal lathe

A horizontal lathe and spindle box technology, which is applied to metal processing mechanical parts, driving devices, metal processing equipment, etc., can solve the problems of low precision, poor rolling support rigidity, unstable work, etc., and achieves high working precision and radial direction. High stiffness and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with accompanying drawing:

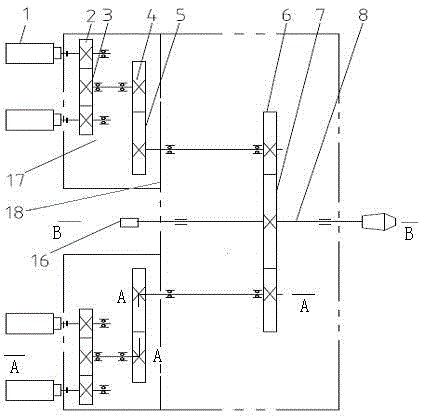

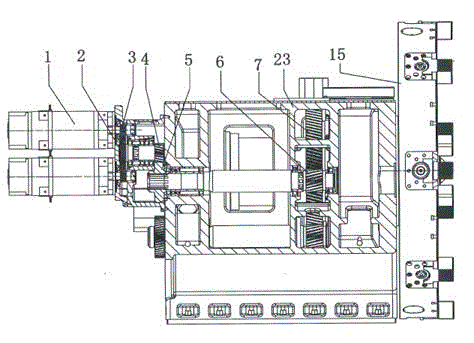

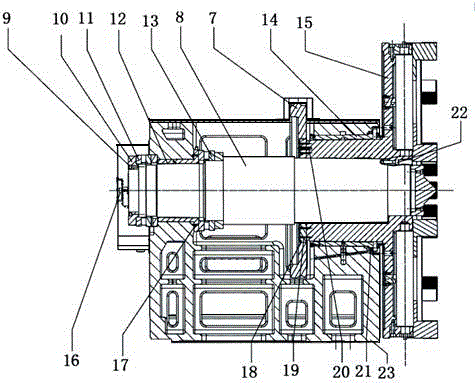

[0015] A spindle box of an ultra-heavy CNC horizontal lathe, which is provided with a main drive shaft 8, a faceplate 15, a spindle box body 23, a front hydrostatic bearing 14, a rear hydrostatic bearing 12, and axial bearings 11 and 13, and is characterized in that the main shaft The rear end of the box body 23 is equipped with a gear box 17, and the gear box 17 is equipped with more than two sets of electronic preloaded parallel servo motor drive systems, and the electronic preloaded parallel servo motor drive systems simultaneously drive the main drive shaft to rotate through three-stage deceleration, In order to realize the stepless speed change between the low speed and high speed of the main transmission shaft 8, an encoder 16 is provided at the rear end of the main transmission shaft 8 to facilitate the position data detection of the main transmission shaft 8 and realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com