Electric pipe hole chamfering trolley

A tube hole and chamfering technology, applied in the field of machinery, can solve the problems of inflexible operation of the radial arm drill, low work efficiency and high production cost, and achieve the effects of shortening the production cycle, reducing labor intensity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

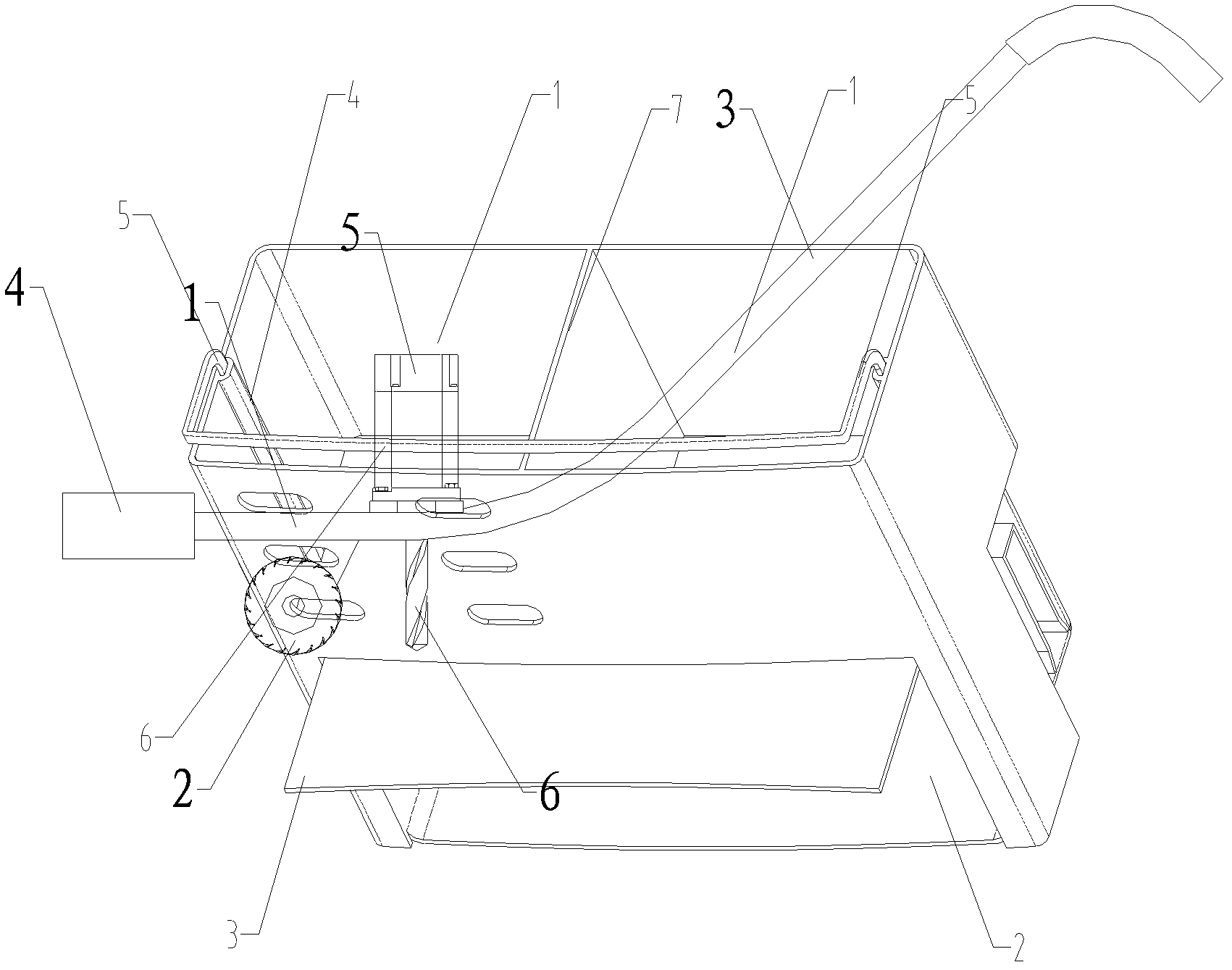

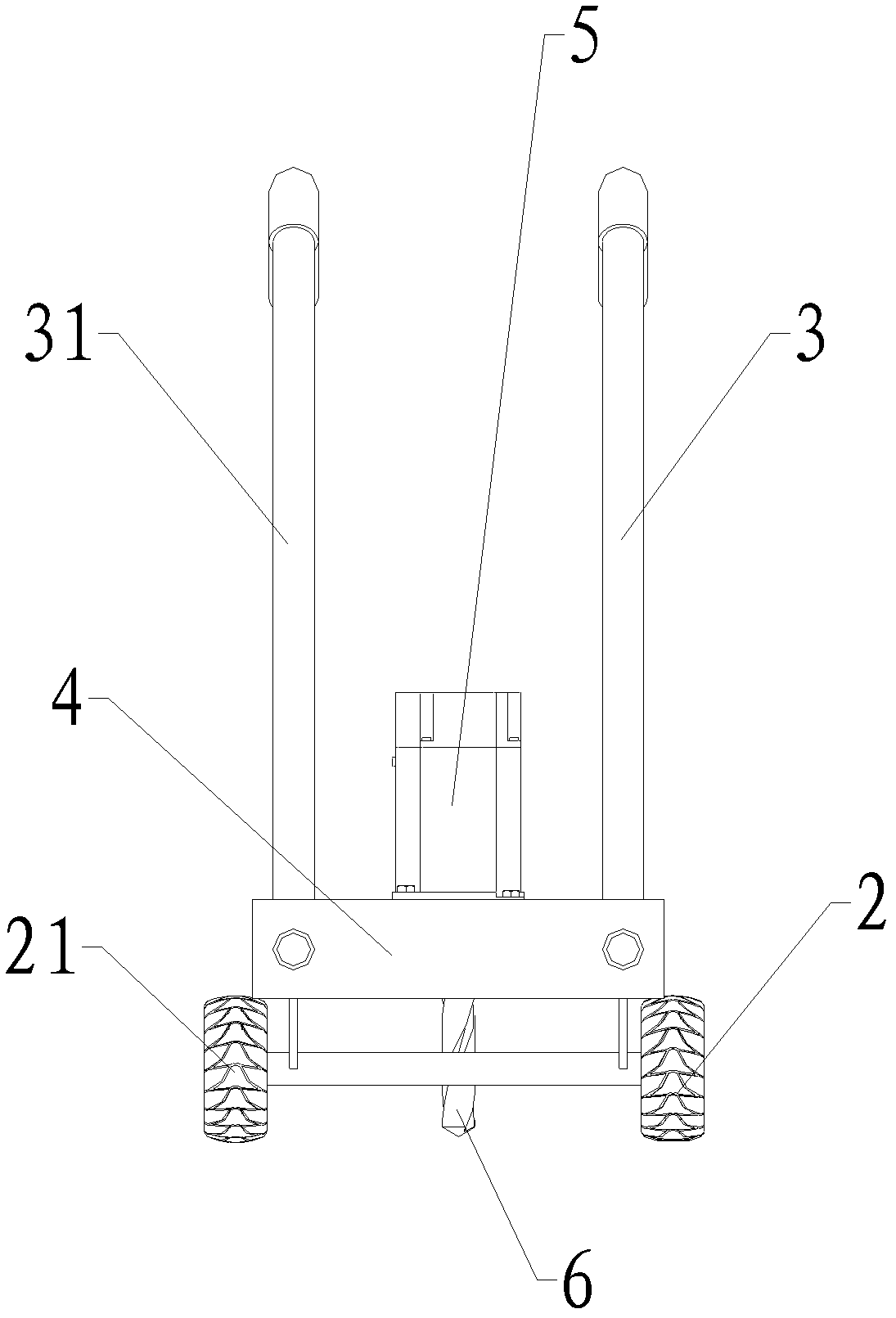

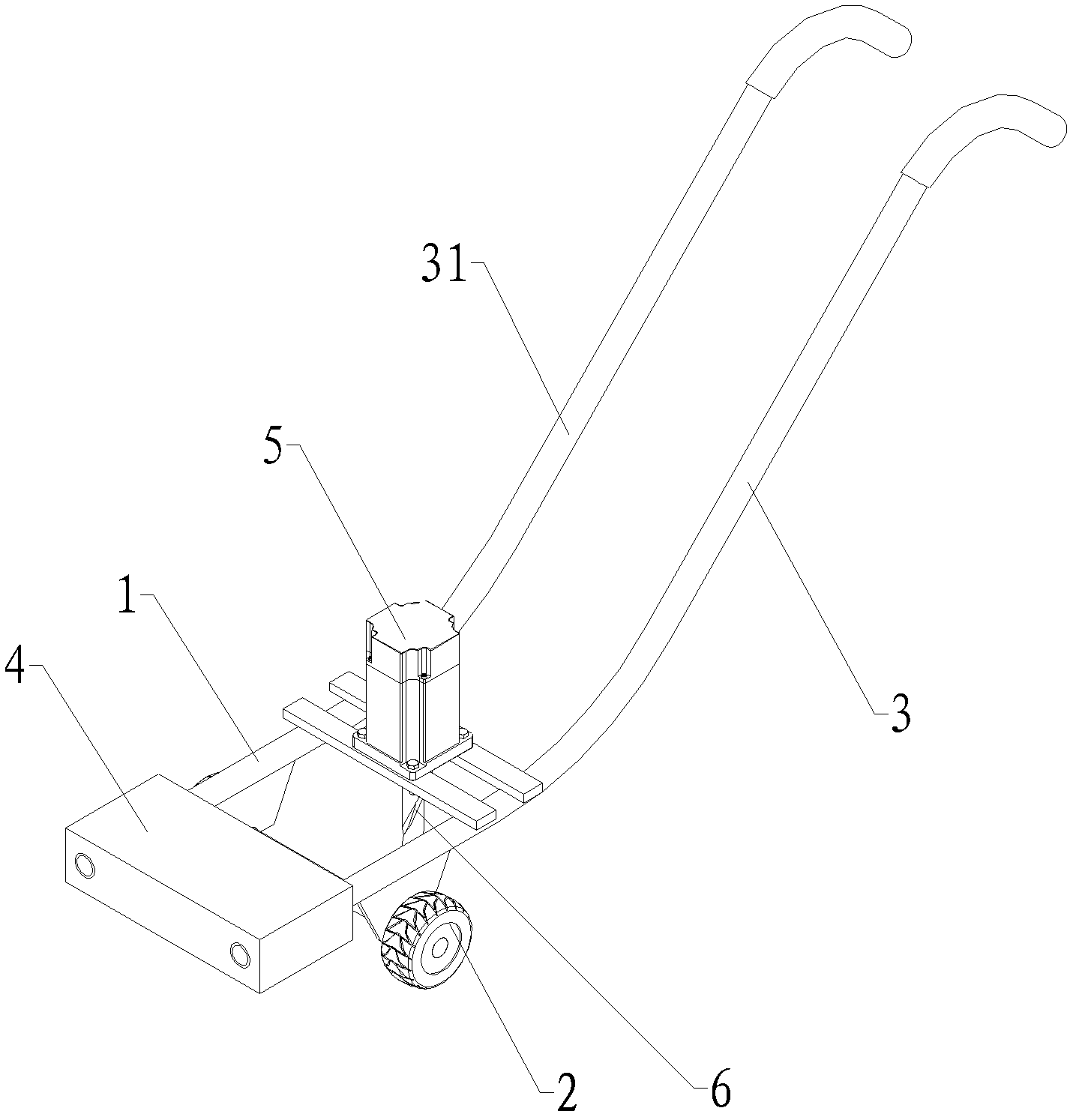

[0014] Examples such as figure 1 , figure 2 , image 3 As shown, the electric pipe hole chamfering trolley includes a car body platform 1, the bottom of the car body platform 1 is provided with wheels 2 and wheels 21, the rear of the car body platform 1 is provided with handrails 3 and 31, and the wheels 2 and 21 The car body platform 1 in the place ahead of the rotating shaft is provided with counterweight 4, and the car body platform 1 at the rear of the wheel 2 and the wheel 21 rotating shaft is provided with a motor 5, and the rotating shaft of the motor 5 is provided with a drill bit 6, and the drill bit 6 is connected to the car body. The platform 1 is vertical and arranged downwards, the rotating shaft of the motor 5 is provided with a drill bit 6, and the ends of the handrail 3 and the handrail 31 are respectively provided with a curved handle, the diameter of the curved handle is 30 cm, and the motor 5 drives the drill bit to rotate when it rotates. Complete the ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap