Method for processing part with thin wall and changed-angle curved surface appearance

A processing method and variable angle technology, which is applied in the processing field of thin-walled variable-angle curved surface shape parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

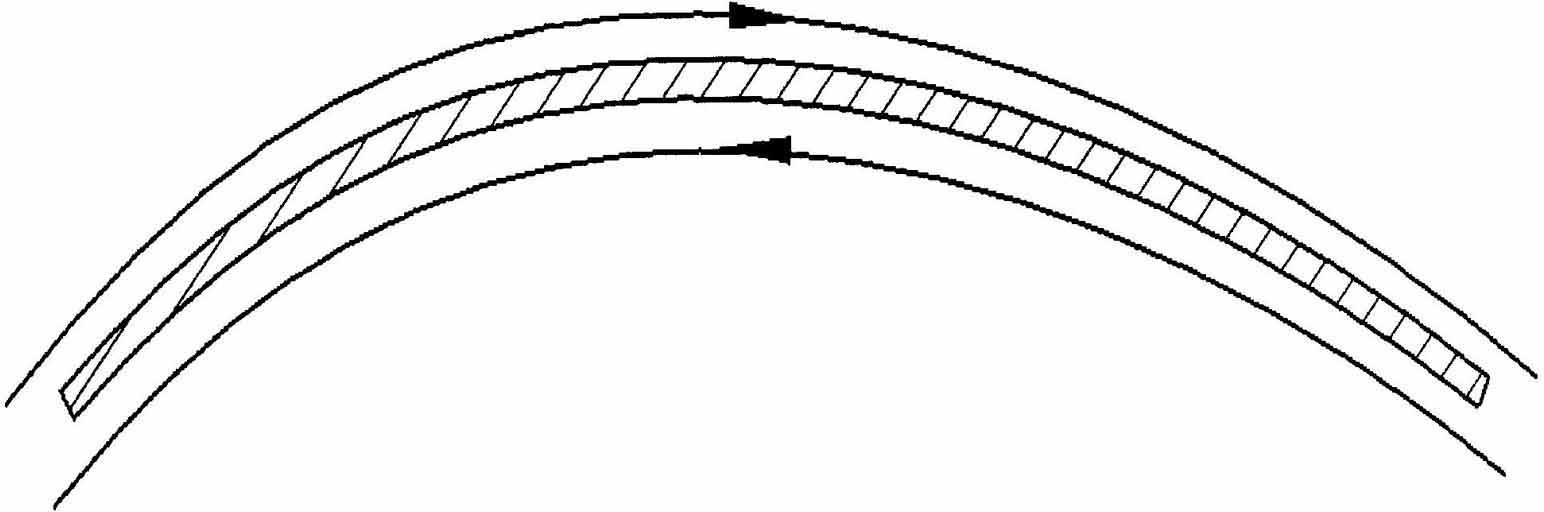

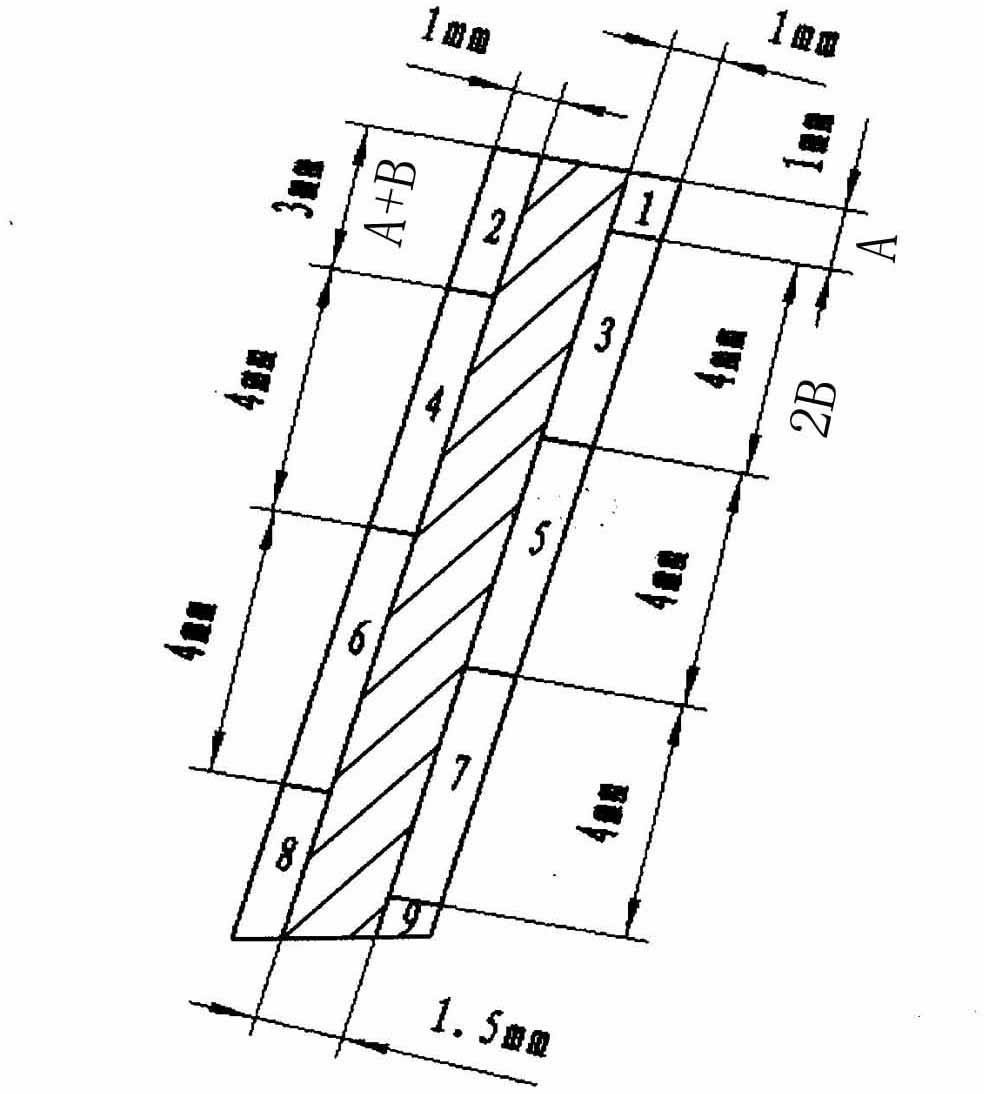

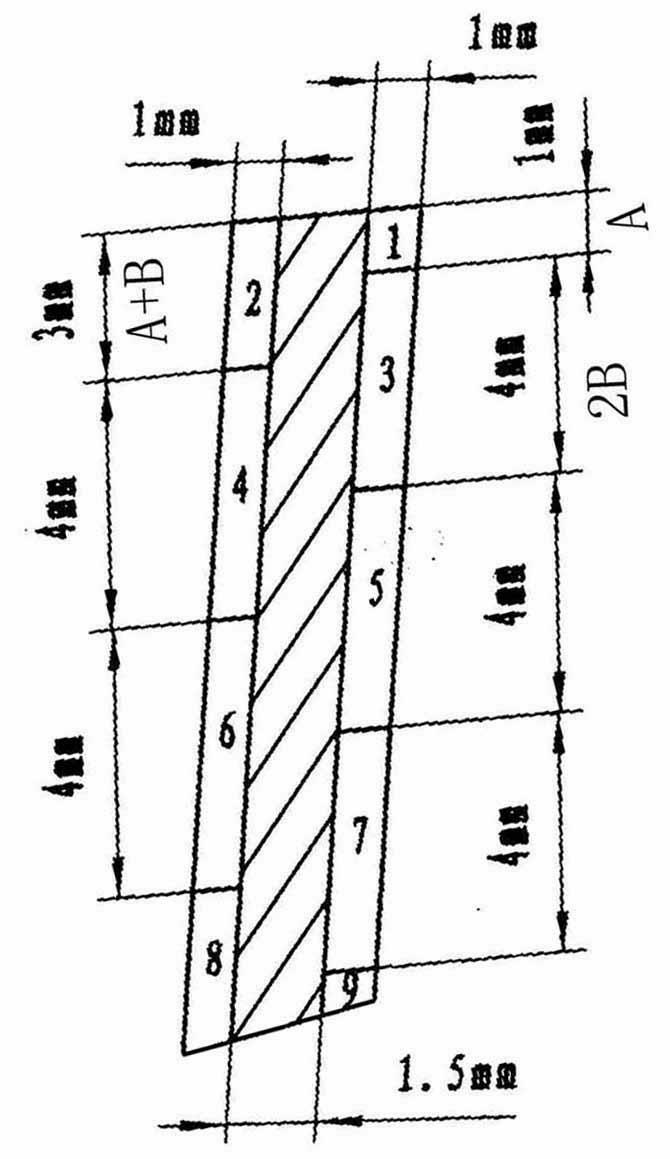

[0008] A method for processing thin-walled curved surface parts with variable angles. The basic steps are to carry out alternately equal-thickness feed milling on the curved surface, such as figure 1 The thickness of the flange shown is 1.5mm, and it is milled to 3.5mm during rough milling, that is, a margin of 1mm is left for each of the inner and outer shapes, and the processing direction of the inner and outer shapes is the direction of the arrow, as shown figure 2 As shown, first determine the first axial cutting depth of the front is 1mm and the milling load-bearing width is 2mm, then the axial cutting depth of the front is 1mm, and the reverse axial cutting depth is 3mm after turning over, so that there is a margin of 2mm on the front. The supporting function, and then the axial feed distance of turning over multiple times is 4mm, so as to ensure that each time the opposite side has a load-bearing width of 2mm, until the remaining width of the front and back sides is les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com