Open-close wire guiding water jet plate for high-speed reciprocating wire-feeding wire-cut electric discharge machine

A technology of reciprocating wire and EDM wire, used in electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of poor limit effect, inconvenient wire threading, etc., to achieve reliable and stable electrode wire, easy to open and Effect of closing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

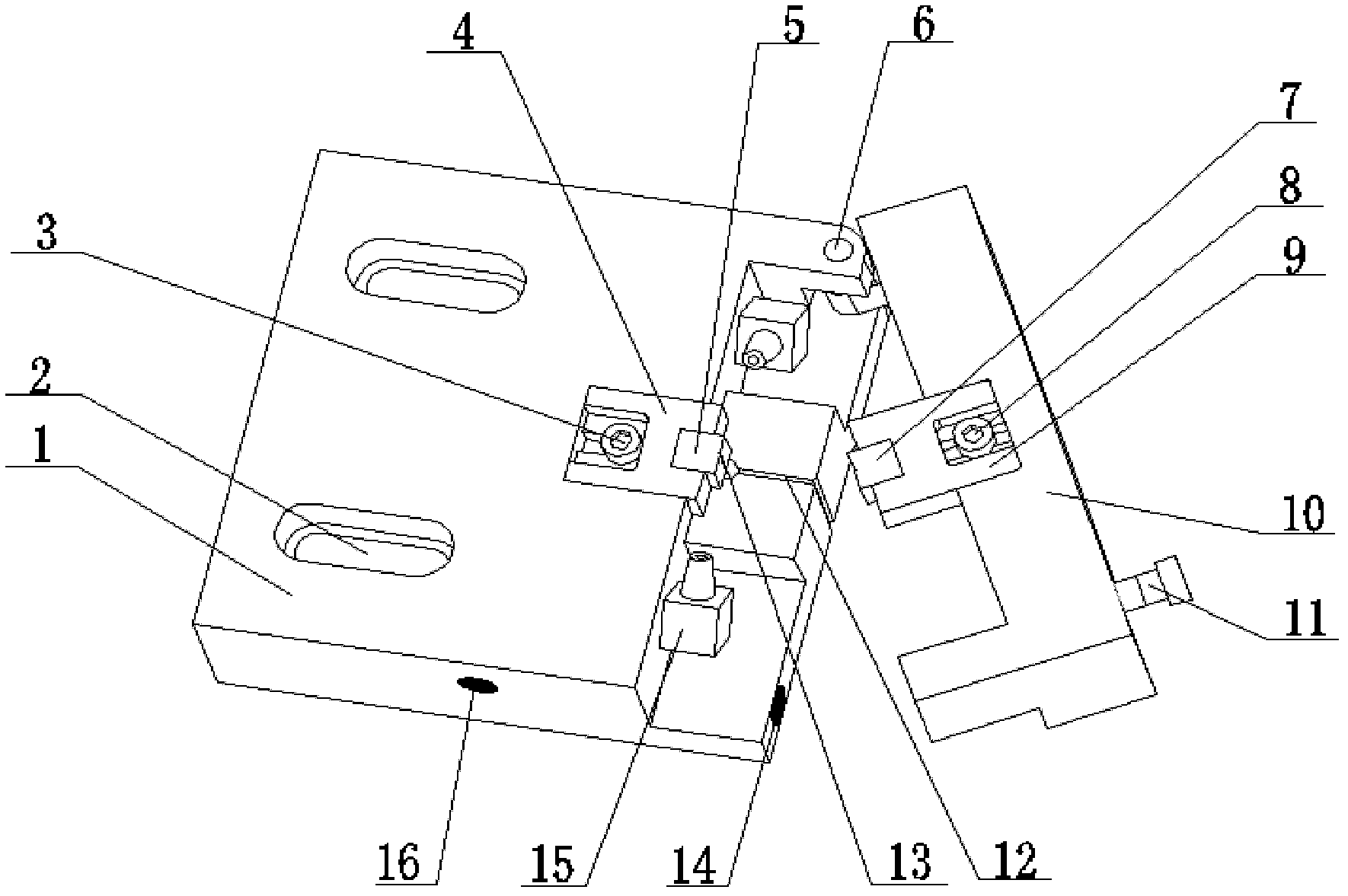

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

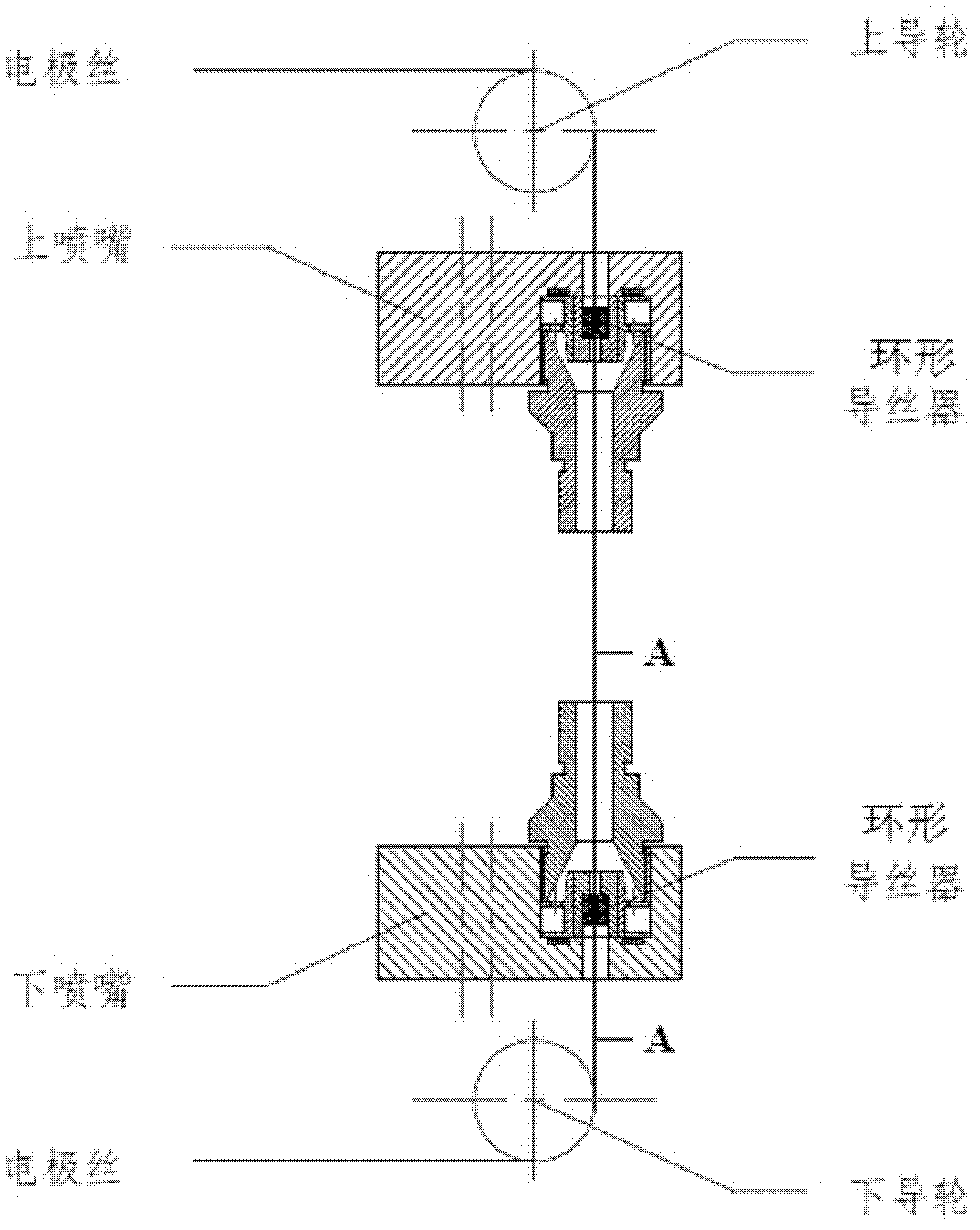

[0023] like image 3 , 4 shown.

[0024] A high-speed reciprocating wire electric discharge machine tool open-close type guide wire water spray plate, which includes a base 1, which is provided with a mounting hole 2 for connecting with the wire arm of the wire-cutting machine tool, and the left jewel seat 4 is installed by screws 3 On the base 1, the left gem block 5 is installed on the left gem seat 4, one side of the left gem block 5 is a plane or is provided with a semicircular or V-shaped through groove, and the right gem block 7 is installed on the right gem seat 9 On the opposite side of the right gem block 7 and the left gem block 5, a semicircular or V-shaped through groove can also be arranged, and the semicircular, V-shaped through groove on the left gem block 5 (or right gem block 7) can also be planar. The groove or plane is combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com