Welder and system capable of managing welding operation

An operation management and welding machine technology, applied in welding equipment, arc welding equipment, comprehensive factory control, etc., to achieve the effect of improving welding quality, reducing labor costs, and improving pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

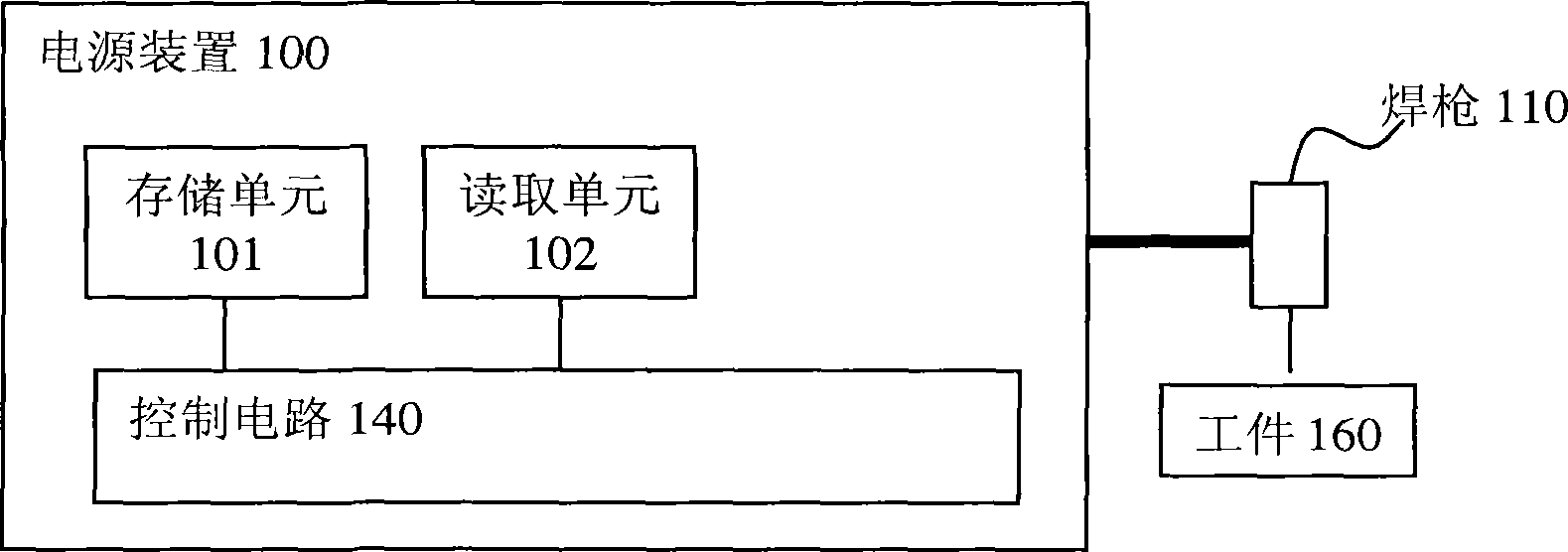

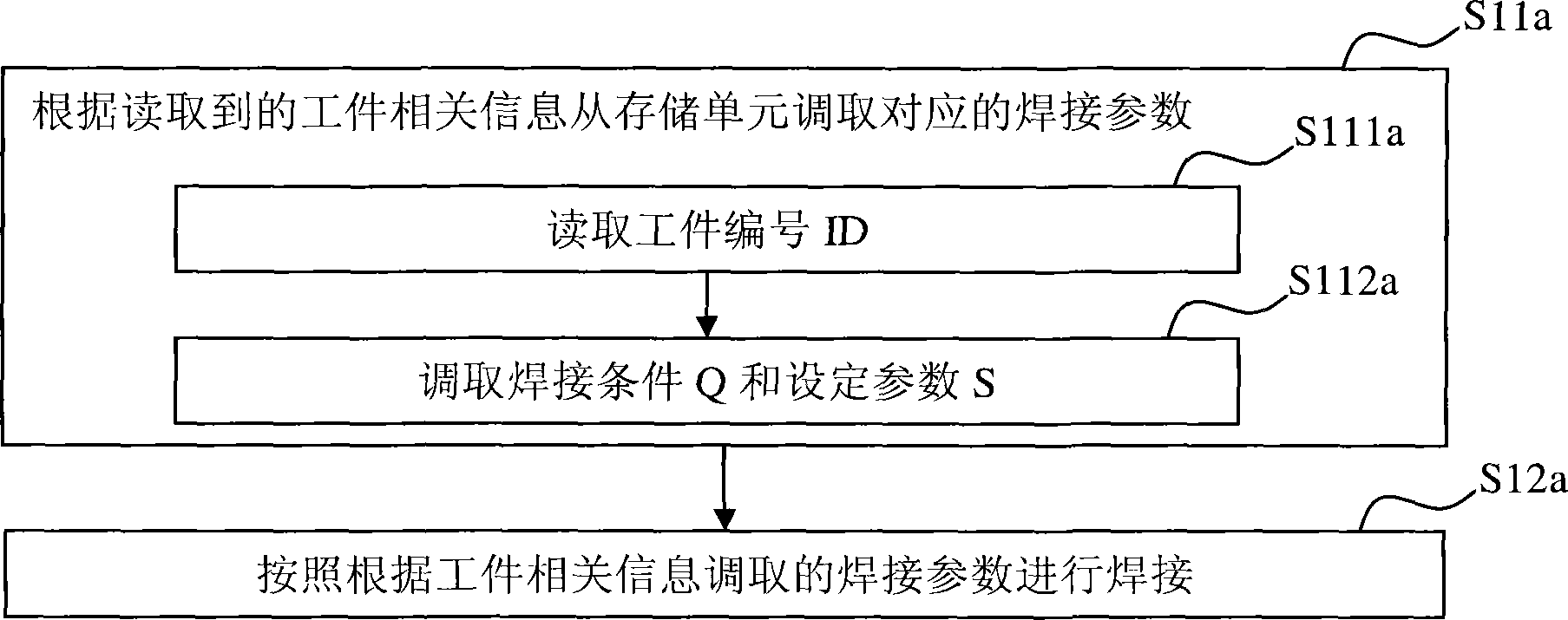

[0040] figure 1 It is a schematic diagram of a welding machine capable of managing welding operations according to the first embodiment of the present invention. Such as figure 1 As shown, the welding machine of this embodiment includes: a power supply device 100 and a welding torch 110 . The welding machine also includes: a control circuit 140; a storage unit 101, which is electrically connected to the control circuit 140, and is used to store workpiece-related information and preset welding parameters, and the workpiece-related information and welding parameters are stored correspondingly; and a reading unit 102, which is electrically connected to the control circuit 140, and is used to read the workpiece-related information attached to the workpiece 160. The reading unit 102 sends the read workpiece-related information to the control circuit 140, and the control circuit 140 reads the The obtained workpiece-related information retrieves welding parameters corresponding t...

Deformed example 1

[0061] This modified example has the same basic structure as the welding machine of the first embodiment, and only the differences between this modified example and the first embodiment will be described below.

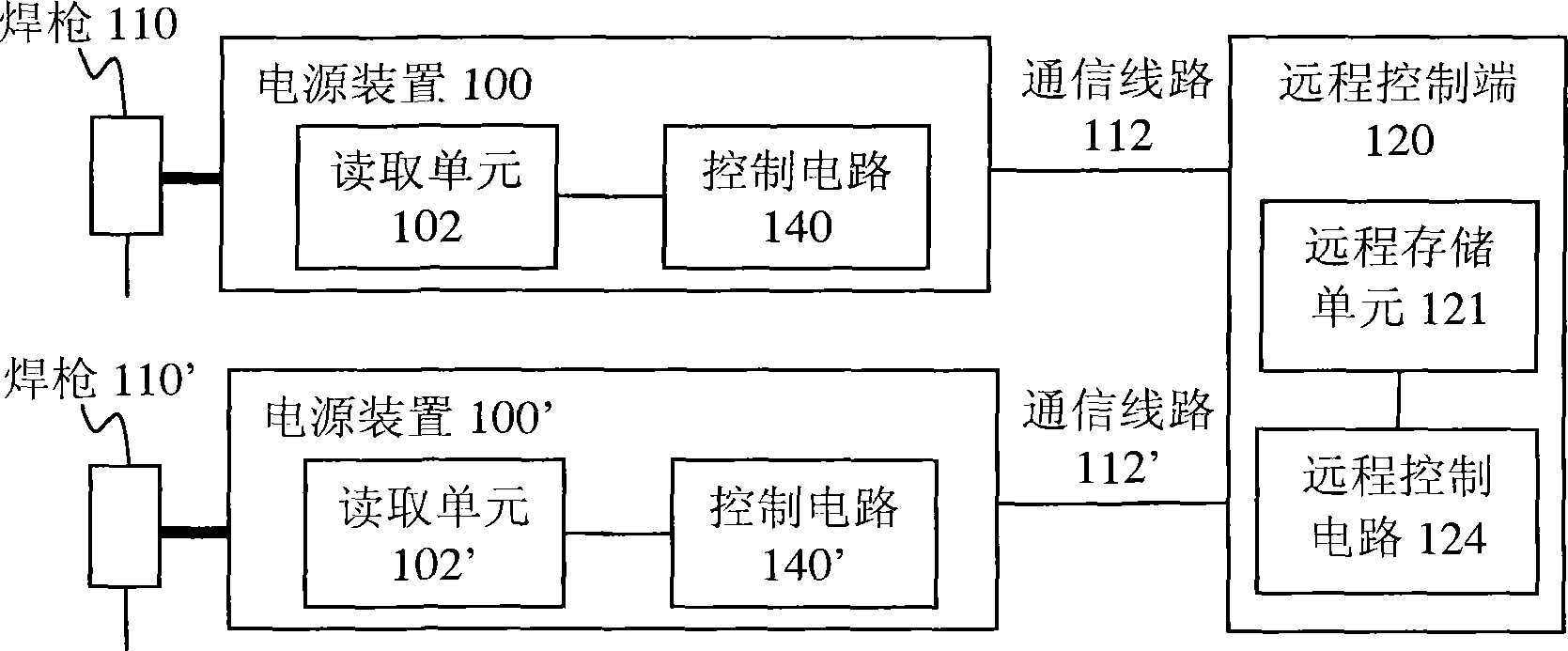

[0062] Figure 4 It is a schematic diagram of a welding machine capable of managing welding work according to Modification 1 of the first embodiment of the present invention. Such as Figure 4 As shown, the welding machine of this modification includes: a control circuit 140; a storage unit 201, which is electrically connected to the control circuit 140, and is used to store workpiece-related information and preset welding parameters, and the workpiece-related information corresponds to the welding parameters storage; and the reading unit 102, which is electrically connected to the control circuit 140, and is used to read the workpiece-related information attached to the workpiece 160, and the reading unit 102 sends the read workpiece-related information to the contr...

Deformed example 2

[0081] This modified example has the same basic structure as the welding machine of the first embodiment, and only the differences between this modified example and the first embodiment will be described below.

[0082] Image 6 It is a schematic diagram of a welding machine capable of managing welding work according to Modification 2 of the first embodiment of the present invention. Such as Image 6 As shown, the welding machine of this modified example includes: a control circuit 340; a storage unit 301, which is electrically connected to the control circuit 340, and is used to store workpiece-related information and preset welding parameters, and the workpiece-related information and welding parameters are stored correspondingly and the reading unit 102, which is electrically connected to the control circuit 340, for reading the workpiece-related information attached to the workpiece 160, the reading unit 102 sends the read workpiece-related information to the control circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com