Method for integrating transmission system of hybrid vehicle and device

A technology of hybrid power system and integration method, which is applied in the field of hybrid power vehicle transmission system integration and devices, can solve problems such as application difficulties, and achieve the effects of reducing coaxiality deviation, reducing longitudinal length, and shortening longitudinal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

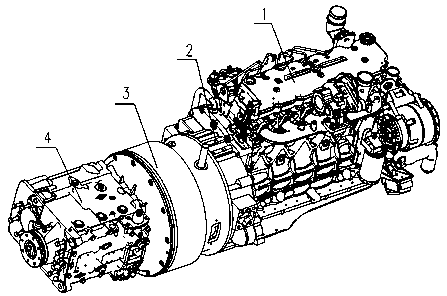

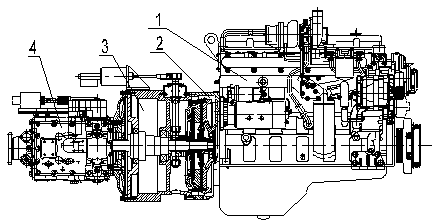

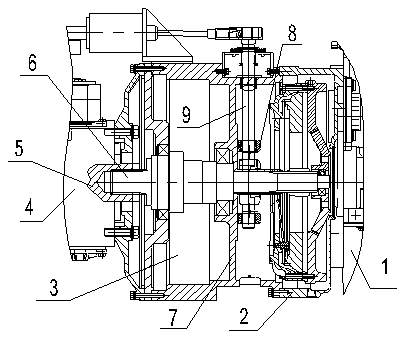

[0025] It can be seen from the accompanying drawings that the present invention relates to a single-shaft parallel hybrid system integration method. The fixed connection between the transmission and the motor, and the motor and the flywheel housing of the engine are all connected in the way of notch positioning, and the input shaft of the transmission is connected to the motor. The output shaft is connected by splines; the input shaft end of the transmission is equipped with a blind hole internal spline, and the output shaft end of the motor is an external spline matching the internal spline at the input shaft end of the transmission, and the external spline of the output shaft of the motor is directly inserted into the The spline connection between the transmission input shaft and the motor output shaft is formed in the spline in the blind hole at the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com