Underground maintenance vehicle for coal mine

A technology for maintaining vehicles and coal mines. It is applied to motor vehicles, goods transport vehicles, and vehicles used for freight transportation. It can solve the problems of inconvenient climbing, troublesome maintenance of lighting equipment, etc., and achieve the effect of ensuring safety and saving labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

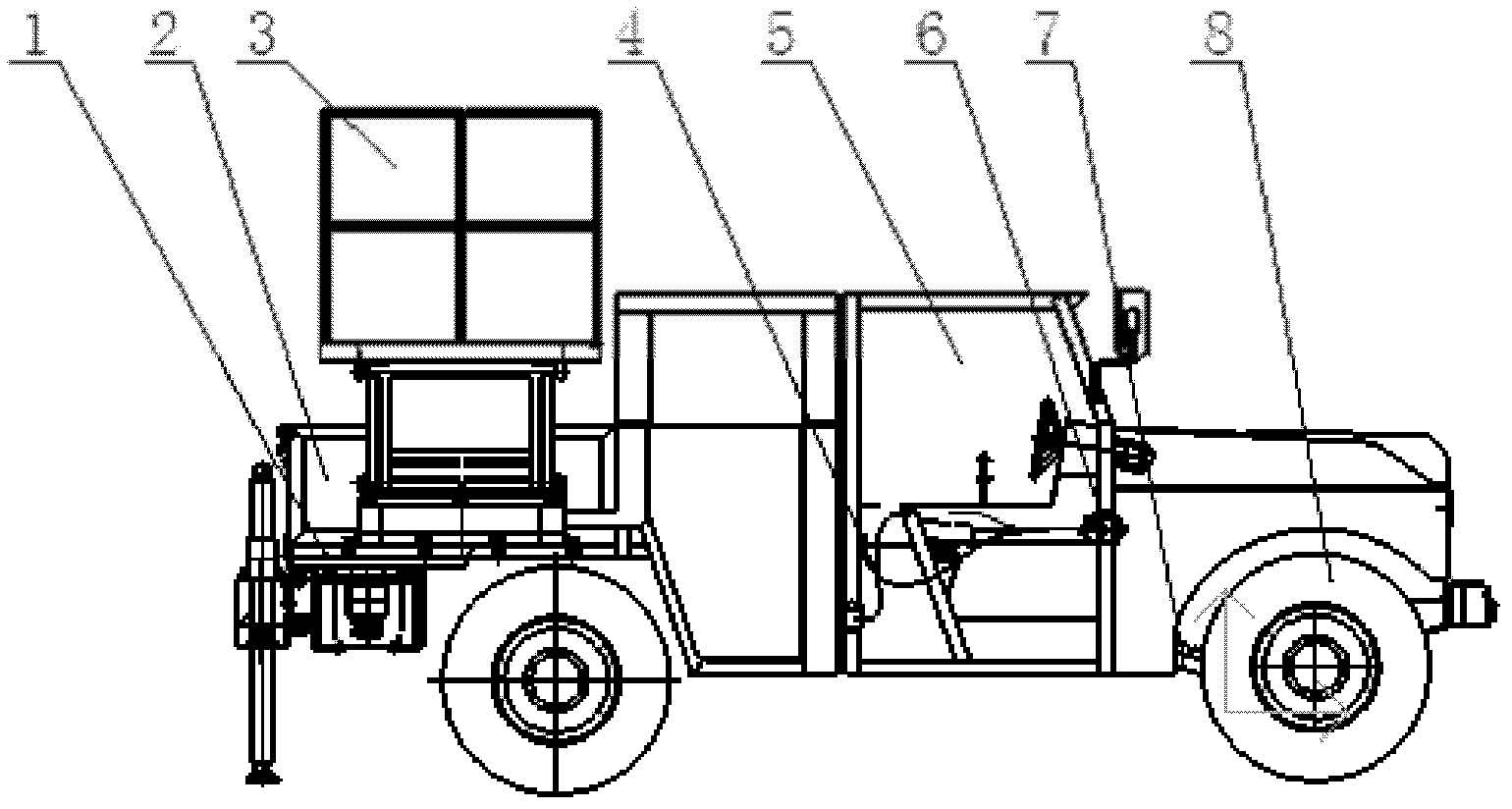

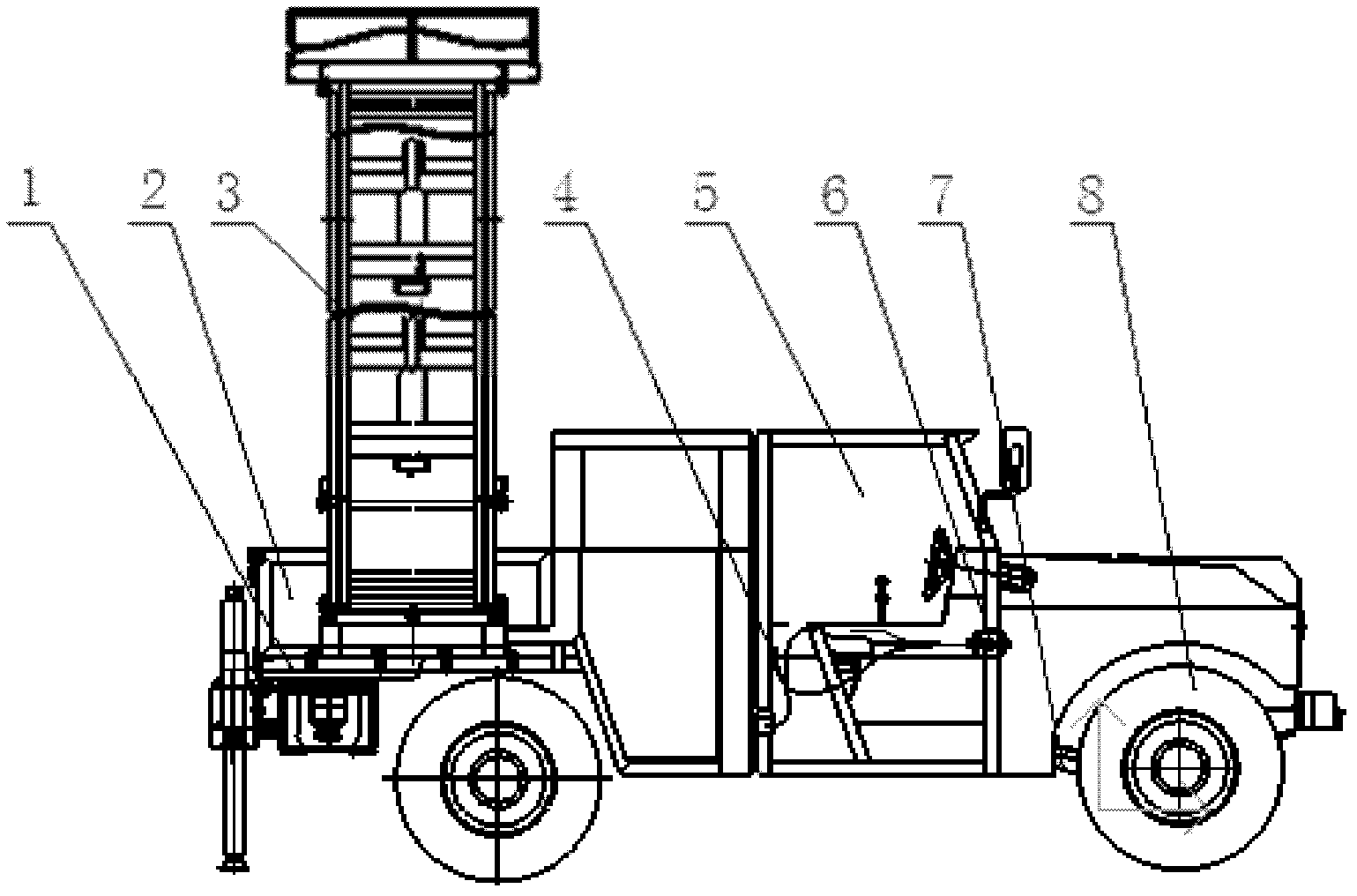

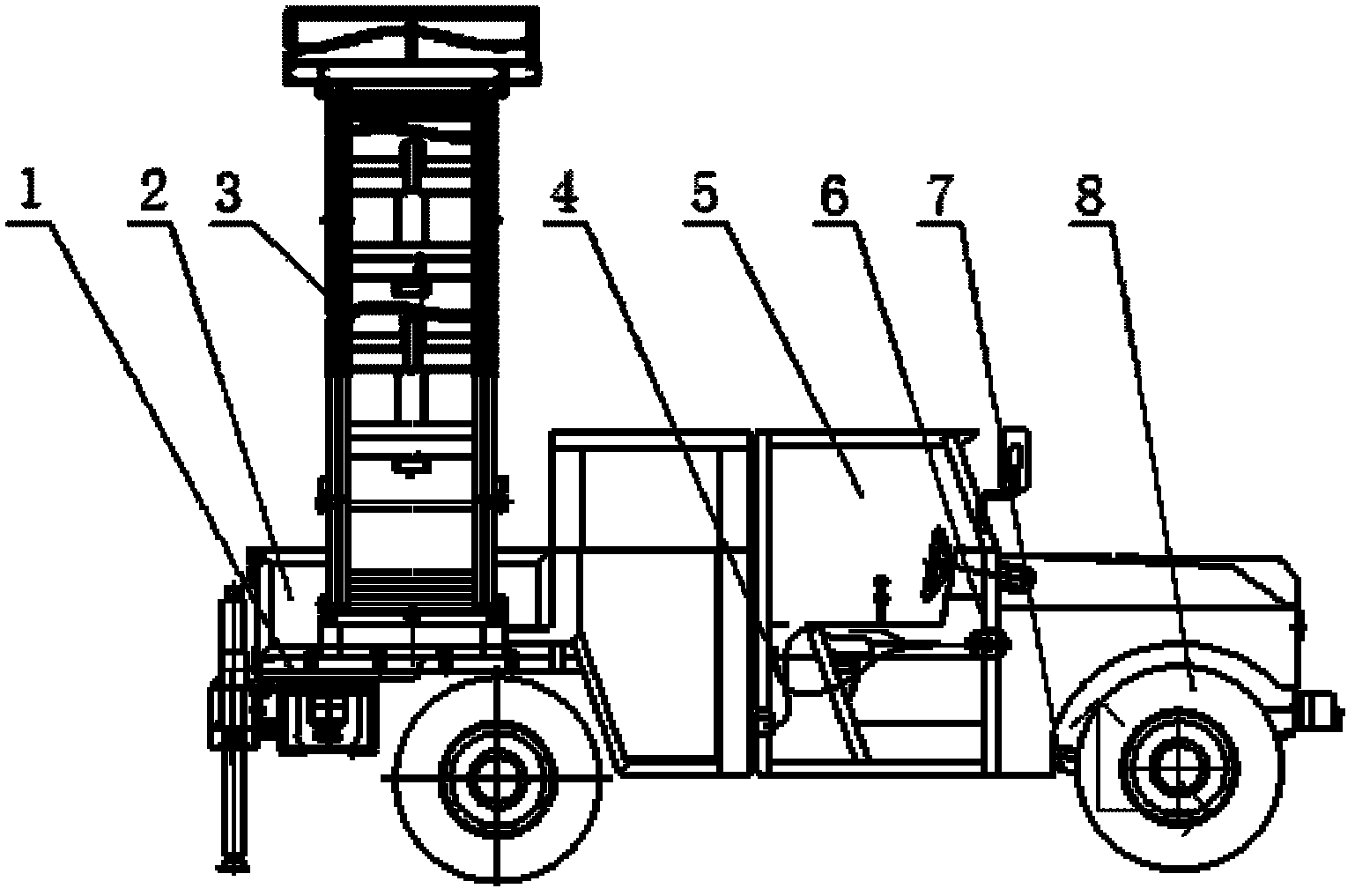

[0018] Such as Figure 1-2 As shown, the coal mine underground maintenance vehicle adopts a trackless rubber-tyred vehicle, including a frame 1, a compartment 2, a hydraulic lifting platform 3, a fuel supply system 4, a cab 5, a hydraulic system 6, a transmission system 7 and a walking system 8. A carriage 2 is arranged above the rear end of the vehicle frame 1 , and a hydraulic lifting platform 3 capable of moving up and down is arranged on the top 2 of the carriage. The hydraulic lifting platform includes a telescopic oil cylinder and a mobile platform arranged on the top of the telescopic oil cylinder. The cylinder rod of the telescopic oil cylinder is directly below the mobile platform. A hydraulic system 6 is arranged on the frame 1, and the hydraulic system 6 is connected to the telescopic oil cylinder through pipelines. , There are protective fences around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com