Bottle pushing device for freeze dryer

A technology of freeze-drying machine and transmission mechanism, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of difficulty in meeting the working space requirements of the servo electric cylinder, long working stroke of the servo electric cylinder, and large space occupation, and achieves a compact structure. , The effect of convenient control and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

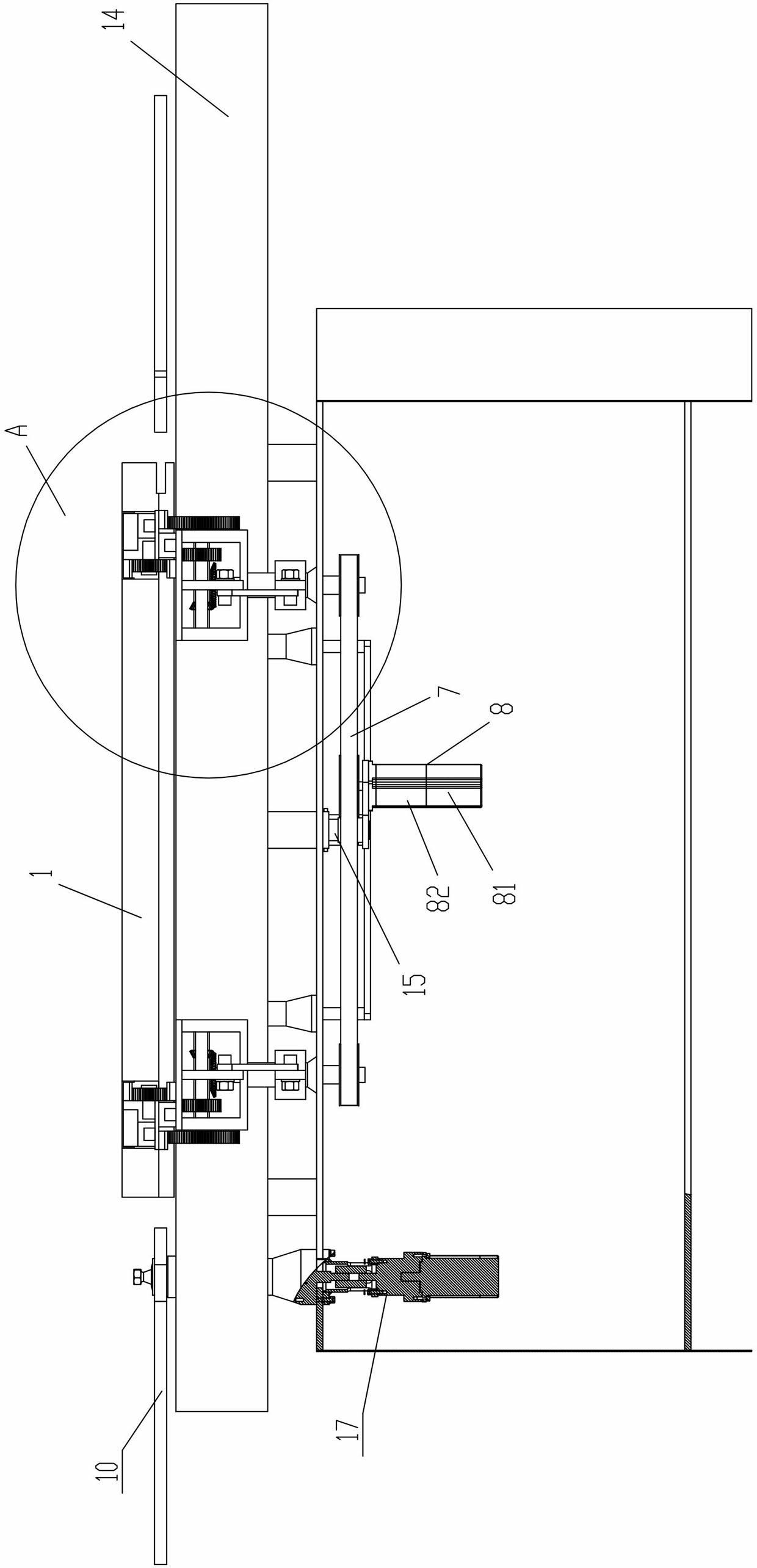

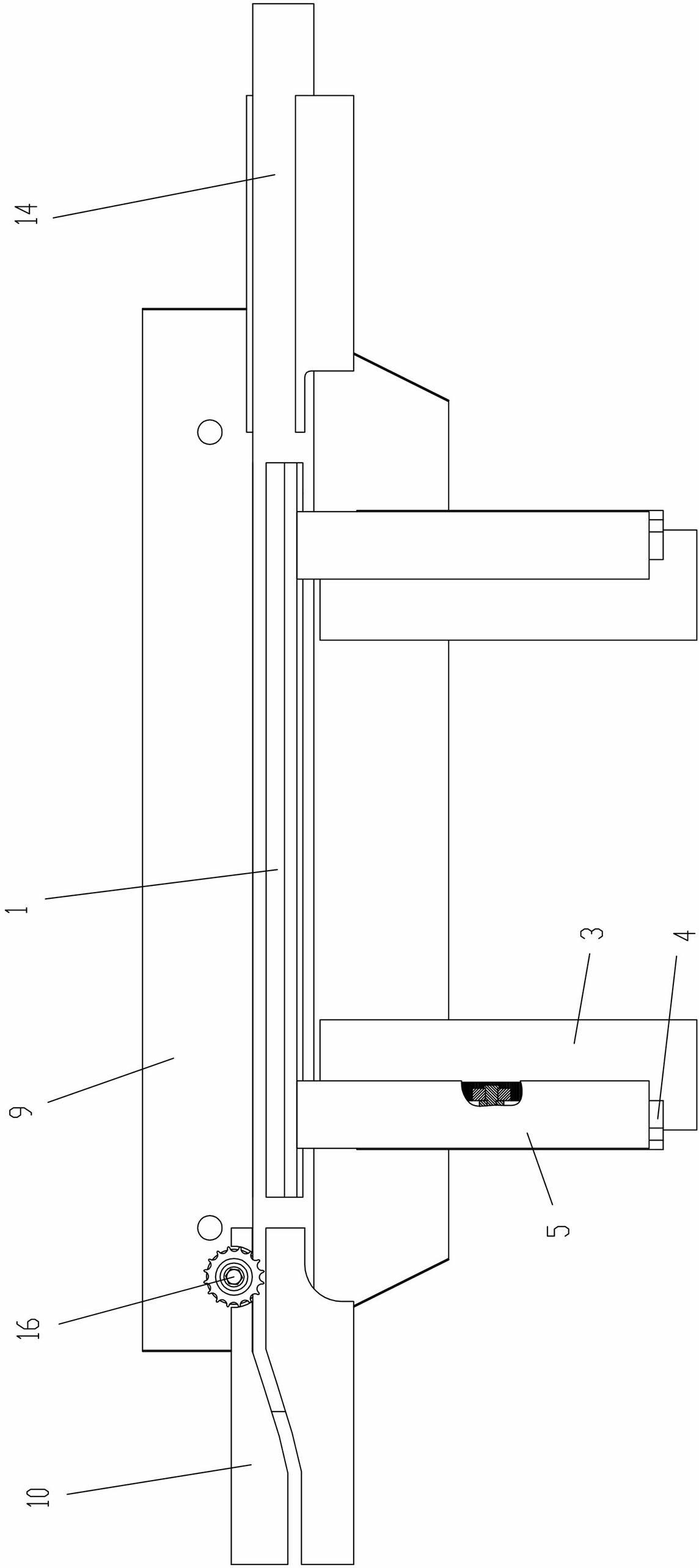

[0027] Such as figure 1 As shown, the bottle pushing device for a freeze dryer of the present invention includes a bottle pushing block 1, a motor part 8 and a transmission part for converting rotary motion into a linear motion, and the bottle pushing block 1, a transmission part and a motor part 8 connected in turn. The transmission part can convert the rotary motion of the motor part 8 into a linear motion, so as to drive the bottle pushing block 1 to make a linear motion of pushing the bottle.

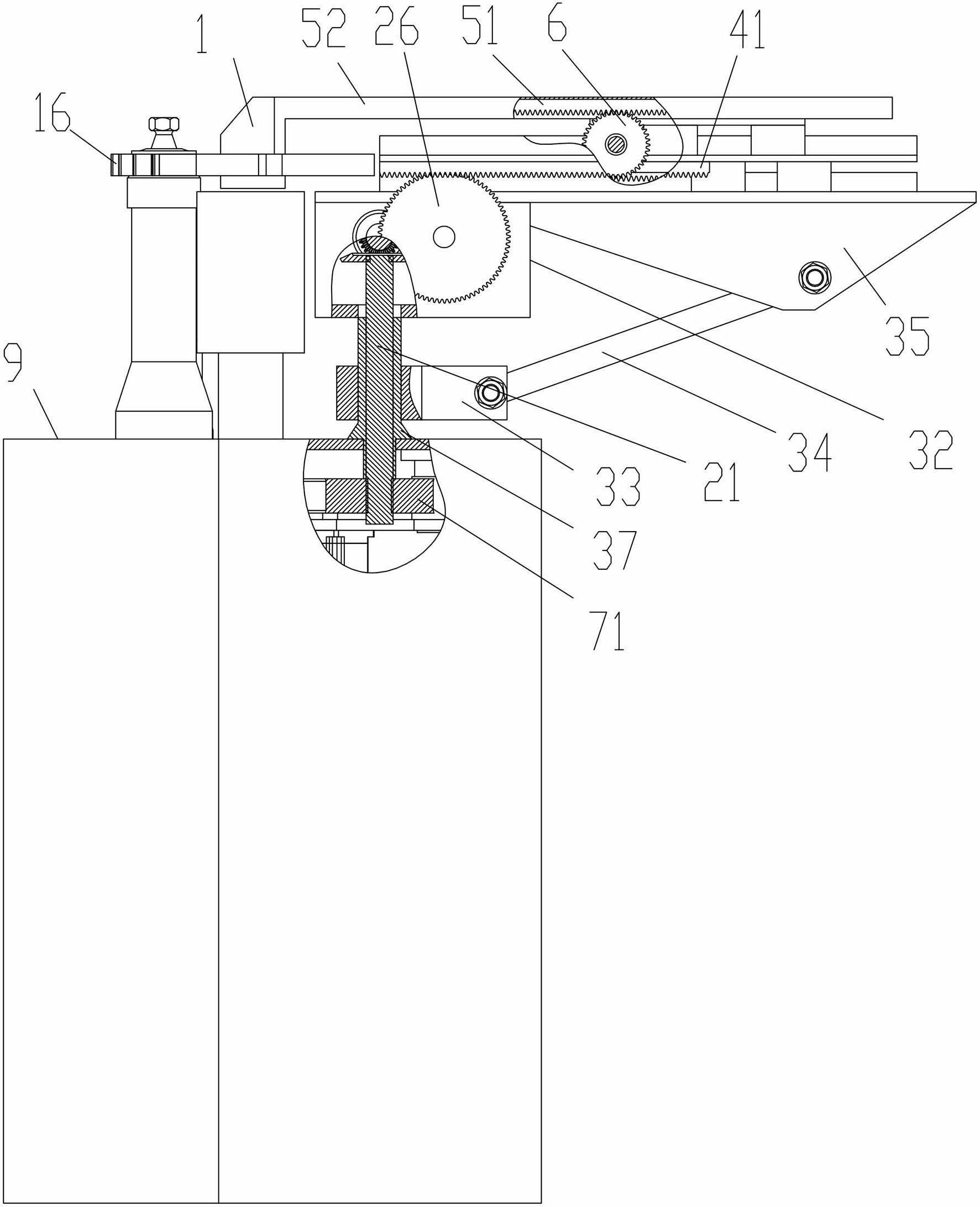

[0028] In this embodiment, the transmission components include a rack and pinion transmission mechanism connected to the bottle pushing block 1, and the rack and pinion transmission mechanism includes a gear transmission group and a side rack 41 (see Figure 4 ). The gear transmission group is installed on a base 3 and driven by a motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com