Rice wine self-raising flour and method thereof for brewing rice wine

A technology for self-rising flour and rice wine, applied in the preparation of alcoholic beverages and other directions, can solve the problems of precipitation, water absorption and softening, affecting the appearance and taste of rice wine, and complicated operation to expand glutinous rice flour. , appearance and taste good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of rice wine self-rising powder

[0029] (1), the preparation of No. 1 rice wine self-rising powder

[0030] Put 99g of puffed glutinous rice grains, 0.5g of rice wine koji and 0.5g of xanthan gum in a clean plastic box, close the lid tightly, shake and mix by hand for 2 minutes, take it out to make self-rising rice wine powder, put it in a clean plastic bag and seal it , stored at room temperature for later use, and compiled as No. 1.

[0031] (2), the preparation of No. 2 rice wine self-rising powder

[0032] Put 98.5g of puffed glutinous rice grains, 0.5g of rice wine koji and 1g of xanthan gum in a clean plastic box, close the lid tightly, shake and mix by hand for 2 minutes, take it out to make rice wine self-rising powder, put it in a clean plastic bag and seal it , stored at room temperature for later use, and compiled as No. 2.

[0033] (3), the preparation of No. 3 rice wine self-rising powder

[0034] Put 97.5g of puffed ...

Embodiment 2

[0041] Embodiment 2: use rice wine self-rising flour of the present invention to brew rice wine

[0042] (1), use No. 1 rice wine self-raising powder prepared in Example 1 to brew rice wine

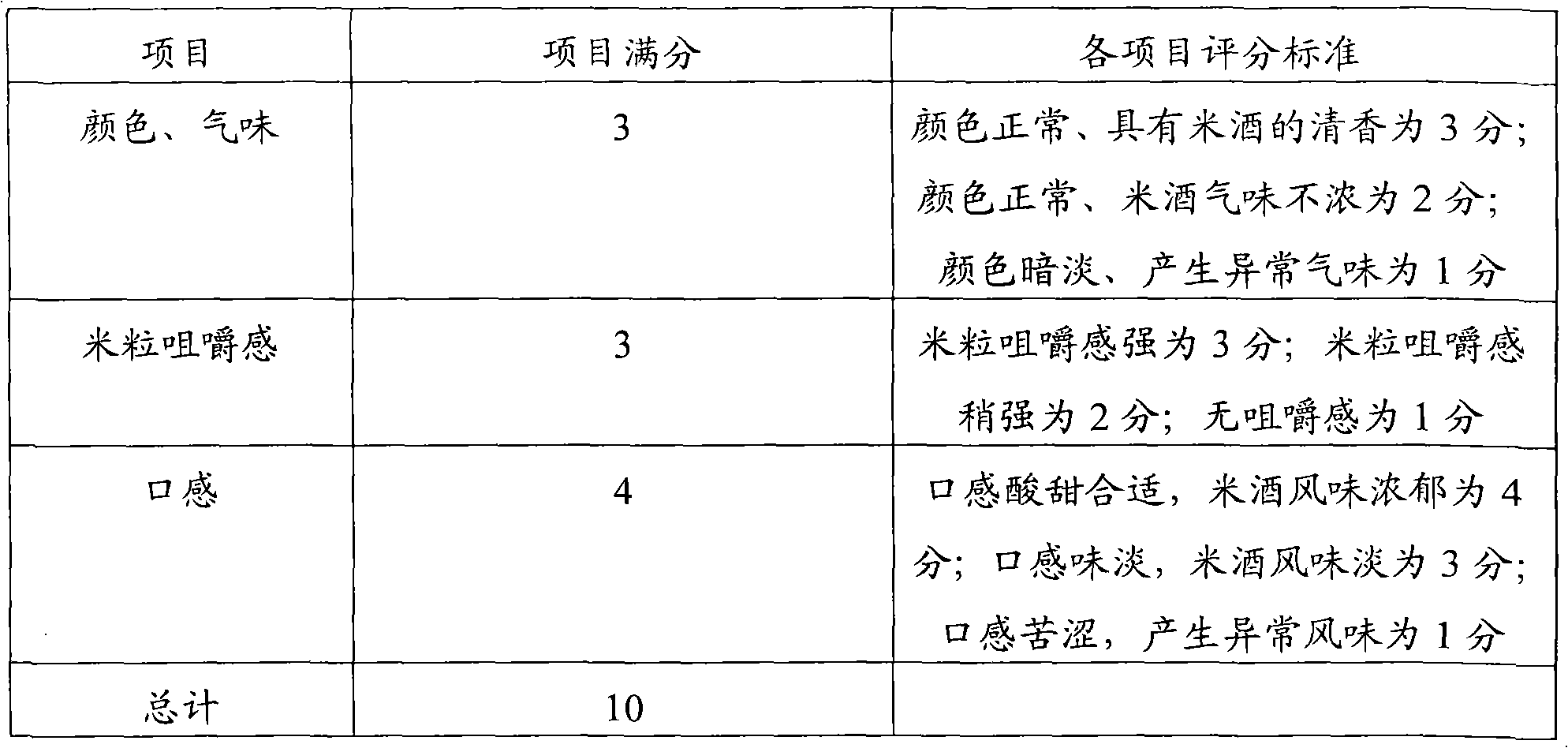

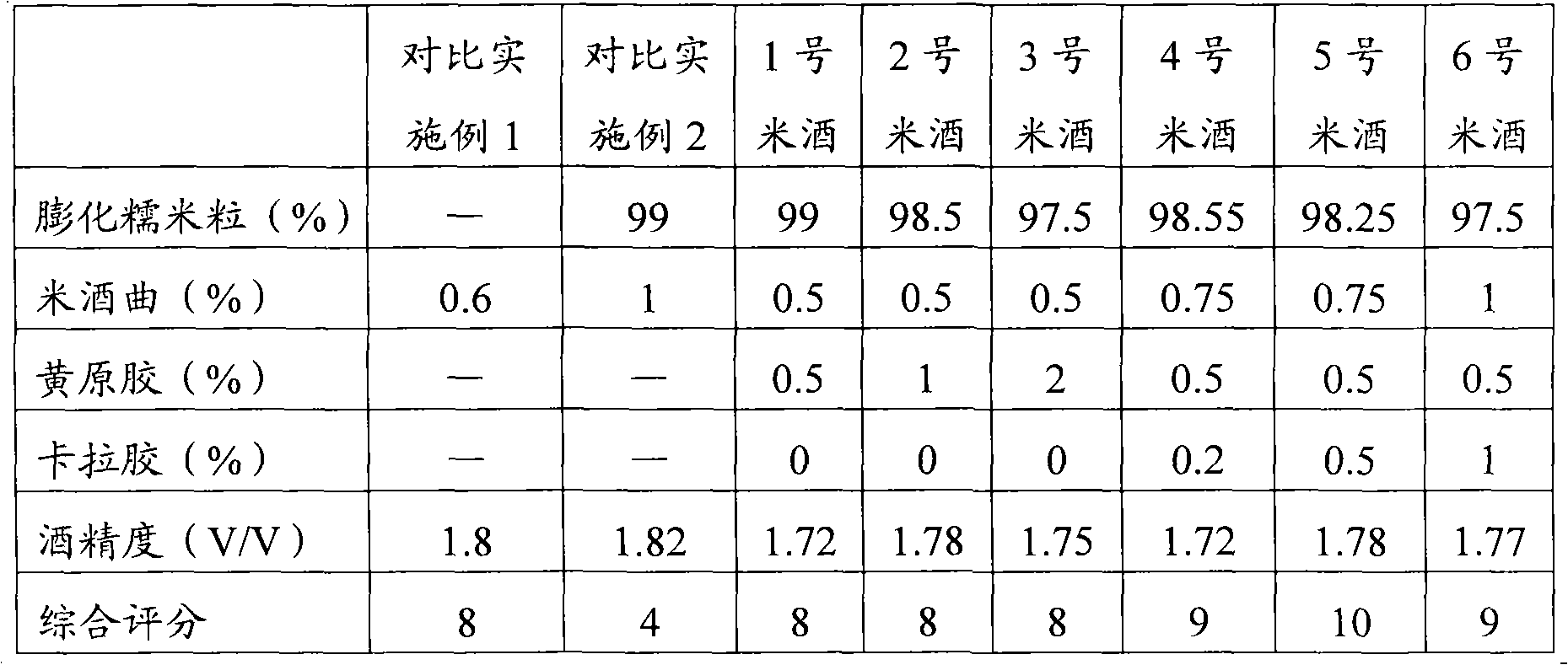

[0043] Add 100 g of pure water to the 100 g of rice wine self-raising powder, and ferment at 28° C. for 40 hours to prepare rice wine. Detect the alcohol level, and invite 10 professional sensory evaluators to give a comprehensive score on rice wine satisfaction, and take the average value of each score. The specific values are shown in Table 2 below.

[0044] (2), use No. 2 rice wine self-raising flour prepared in Example 1 to brew rice wine

[0045] Add 200 g of pure water to the 100 g of rice wine self-raising powder, and ferment at 30° C. for 38 hours to obtain rice wine. Detect the alcohol level, and invite the above-mentioned 10 professional sensory evaluators to give a comprehensive score on the rice wine satisfaction, and take the average value of each score. The specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com