Method for applying Bayan Obo ore ultra-fine iron powder in sintering

An application method and technology for fine iron, applied in the field of ultra-fine iron powder, can solve the problems of complex process and high manufacturing cost, and achieve the effects of overcoming complex process, simple process and increased solid fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0021] Embodiment 3: Test embodiment for increasing the basicity of sintered ore.

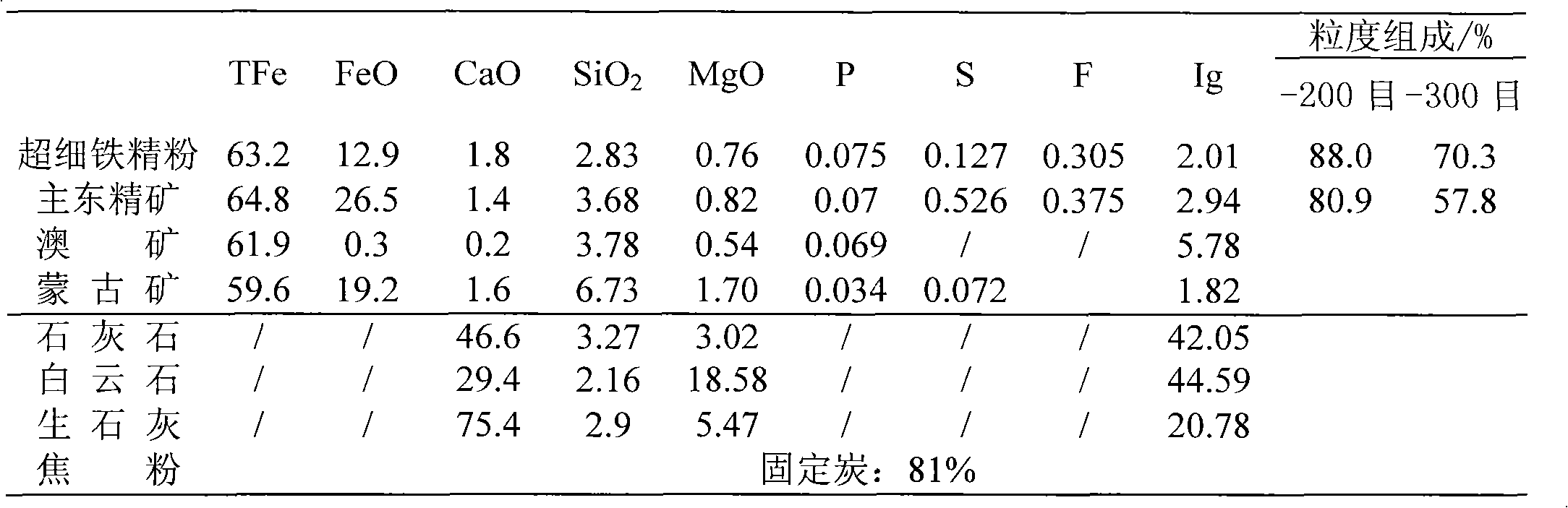

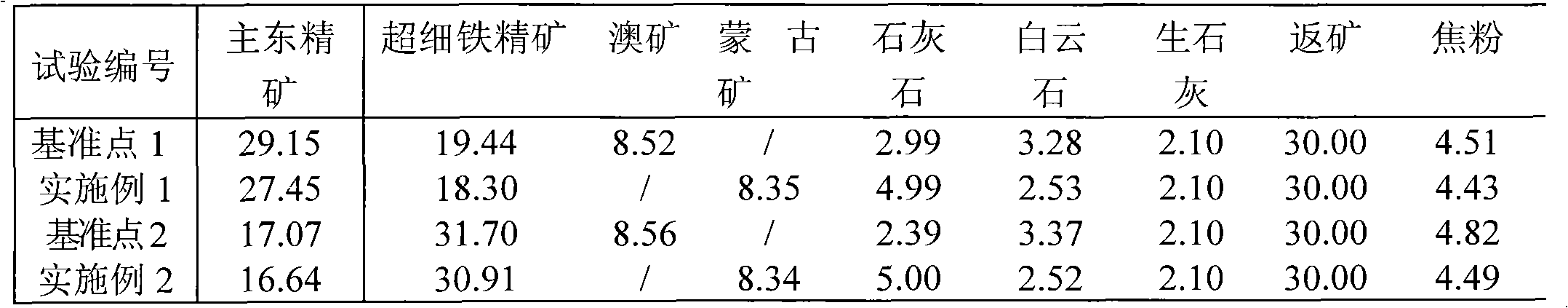

[0022] Example 3 The proportions of various raw materials and fuels for sintering with superfine iron concentrate are shown in Table 4, and the chemical composition and process indicators of sinter with superfine iron concentrate for sintering are shown in Table 5.

[0023] In Example 3, except for 15% Australian ore powder in the iron material of the mixture, all iron materials use ultrafine iron fine powder, and the ratio of ultrafine iron fine powder to iron material is 85%.

[0024] Table 4 sintering and adding ultra-fine iron concentrate various raw materials and fuel ratios (wt%)

[0025]

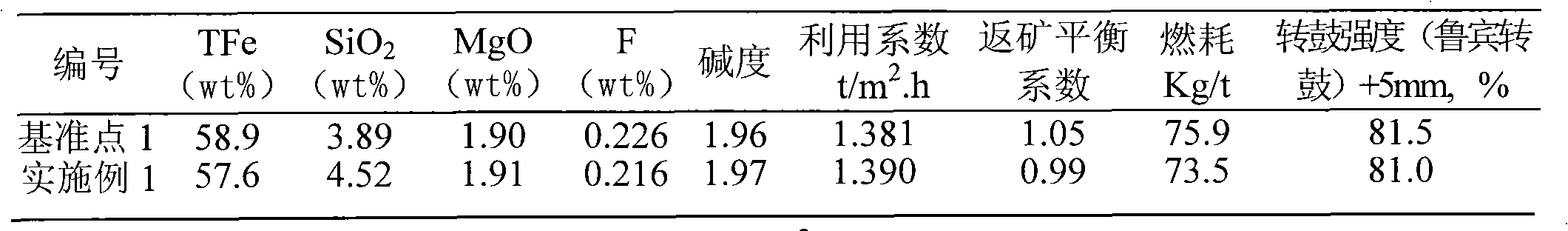

[0026] Table 5 Sinter chemical composition and process index of sinter with superfine iron concentrate

[0027]

[0028] It can be seen from Table 5 that, compared with the reference point, increasing the sinter basicity to 2.04 has a greater effect on improving the sinter utilization coefficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com