Erbium-containing high-temperature titanium alloy and preparation process thereof

A high-temperature titanium alloy, content technology, applied in the field of alloys, can solve problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

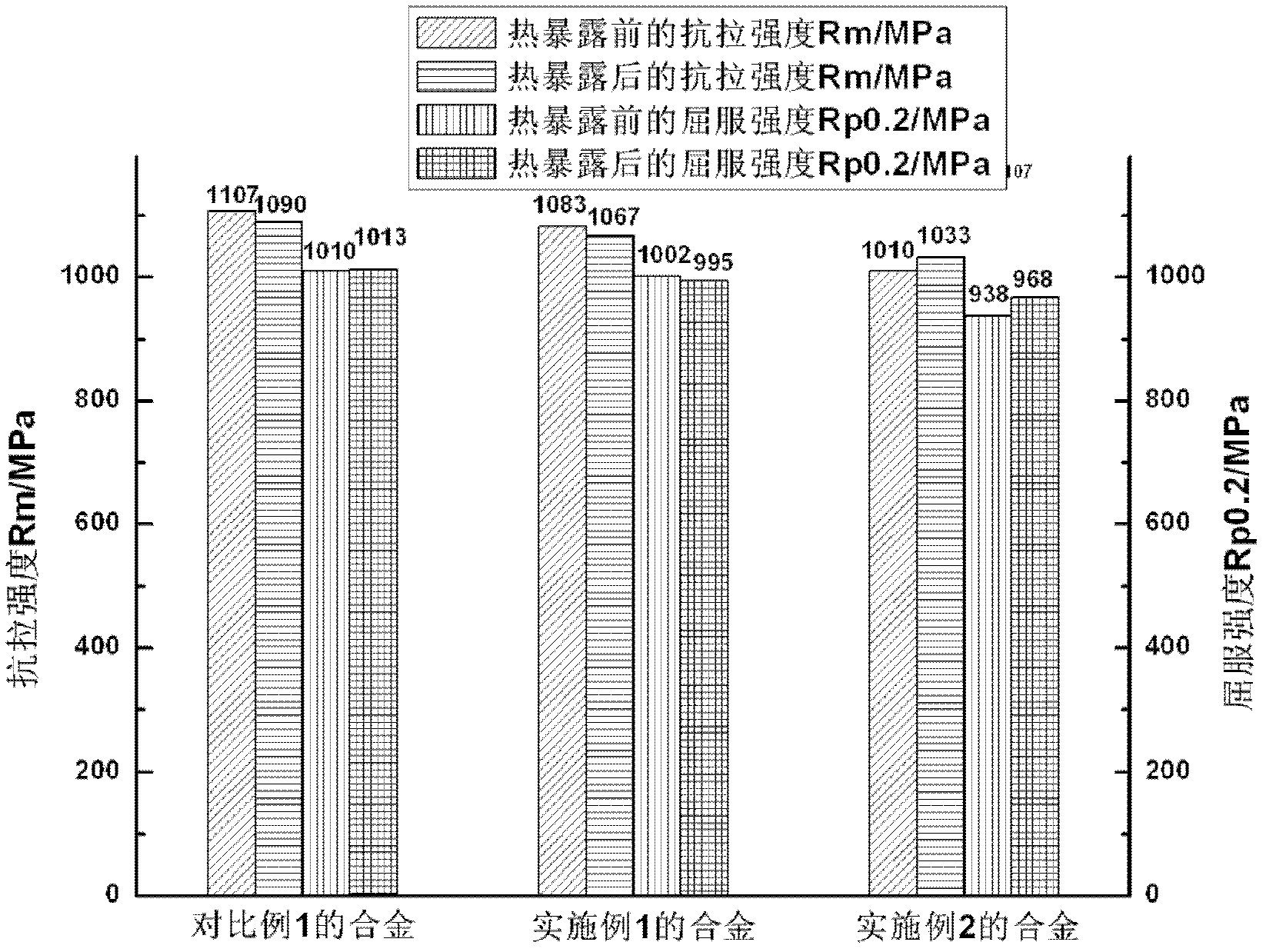

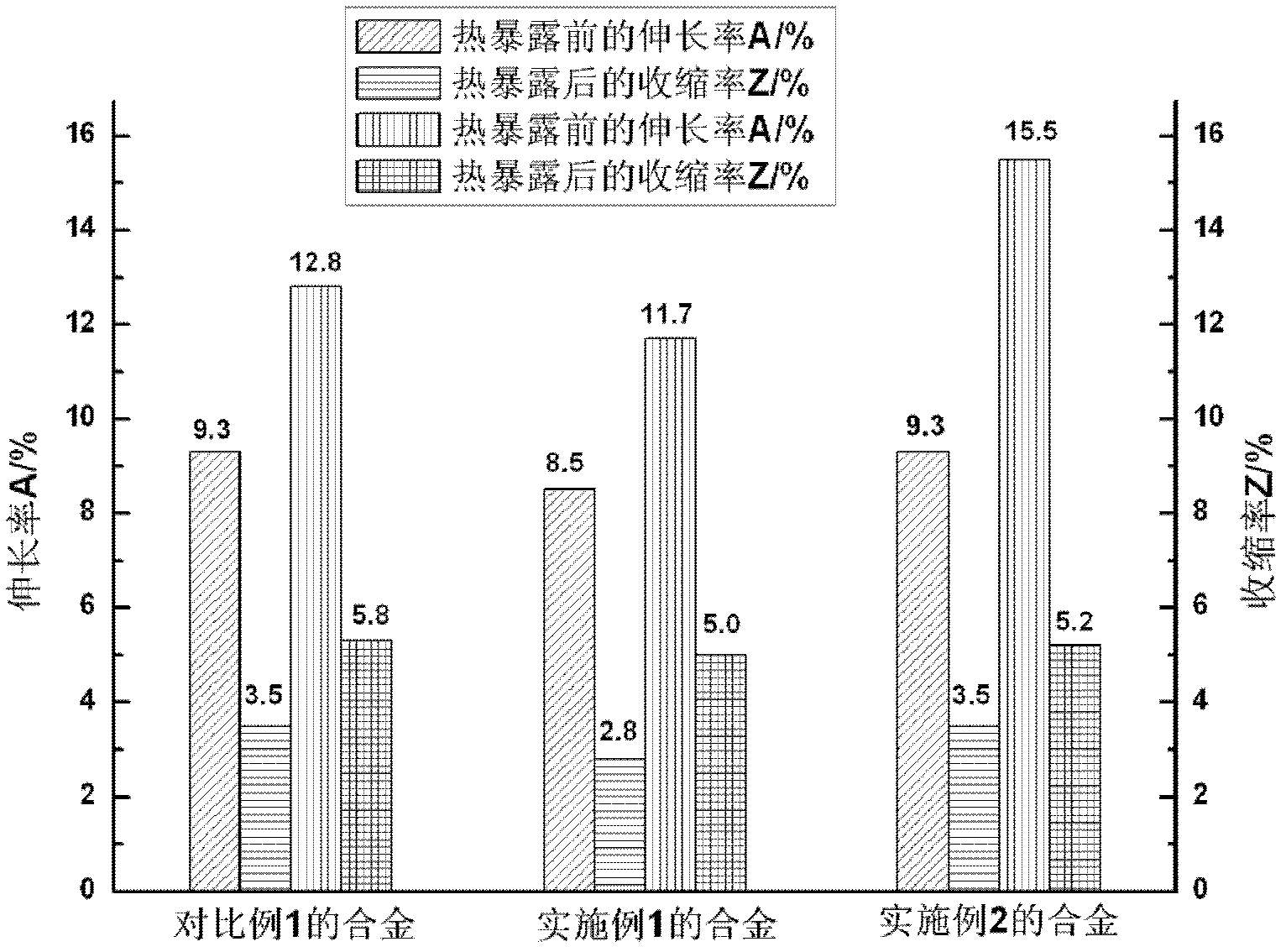

Examples

Embodiment 1

[0048] Commercially available sponge titanium, high-purity Al, high-purity Zr particles, TiSn master alloy, AlMo master alloy, AlNb master alloy and AlSi master alloy are mixed and pressed according to the composition ratio in Table 5 to form a self-consumable electrode. The pole is smelted twice in a vacuum consumable electric arc furnace, and finally an ingot with a weight of 5kg, a diameter of 100mm, and a height of 135mm is obtained.

[0049] Table 5 alloy composition

[0050] chemical composition

Ti

Al

sn

Zr

Mo

Nb

Si

O

Er

content

margin

6

2.5

4

0.3

1

0.35

0.09

0.1

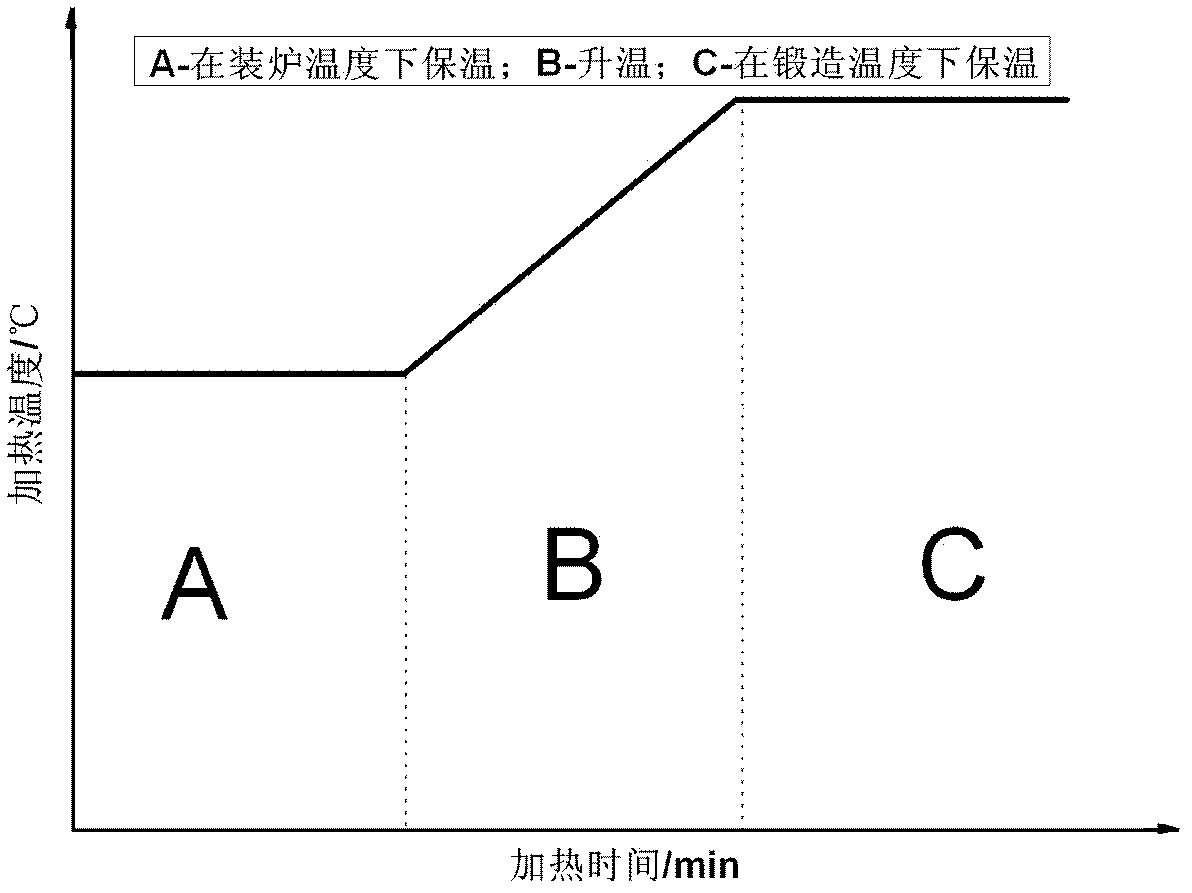

[0051] The ingot is loaded in the furnace at 900°C, kept for 20 minutes, heated up to 1150°C in 40 minutes, kept at this temperature for 20 minutes, then out of the furnace for blank forging, repeatedly upsetting and elongating, so that the deformation of the ingot reaches 50%. Obtain a squa...

Embodiment 2

[0055] Commercially available sponge titanium, high-purity Al, high-purity Zr particles, TiSn master alloy, AlMo master alloy, AlNb master alloy and AlSi master alloy are mixed and pressed according to the composition ratio in Table 7 to form a self-consumable electrode. The pole is smelted twice in a vacuum consumable electric arc furnace, and finally an ingot with a weight of 5kg, a diameter of 100mm, and a height of 135mm is obtained.

[0056] Table 7 alloy composition

[0057] chemical composition

Ti

Al

sn

Zr

Mo

Nb

Si

O

Er

content

margin

6

2.5

4

0.3

1

0.35

0.088

0.1

[0058] The ingot is loaded in the furnace at 900°C, kept for 20 minutes, heated up to 1150°C in 40 minutes, kept at this temperature for 20 minutes, then out of the furnace for blank forging, repeatedly upsetting and elongating, so that the deformation of the ingot reaches 50%. Obtain a squ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com