Traceless joint fabric knitting method of double-needle-bed warp knitting machine

A double-needle bed and warp knitting technology, which is applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of design and development limitations, affecting product strength characteristics, affecting product appearance, etc., achieving simple production methods and improving appearance The effect of improving the degree of comfort and seam strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The production process is: process design of ultra-wide warp velvet flat fabric—yarn preparation—configuration of swing guide needle—arrangement of yarn guide needle control information—machine process adjustment and weaving—fabric finishing:

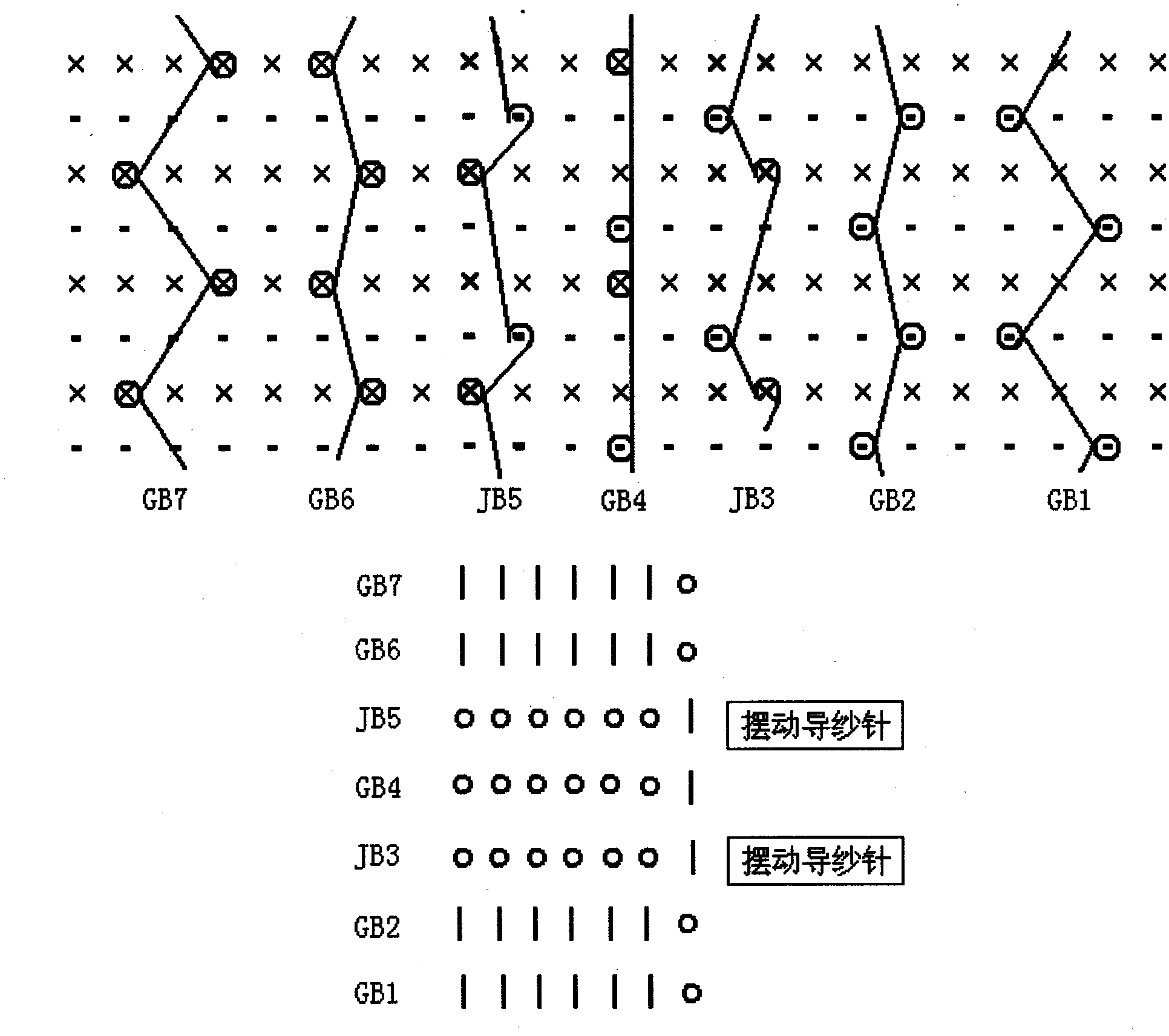

[0036] The process design of the super-wide warp pile flat fabric is as follows: select suitable warp raw materials according to the purpose of the warp pile flat fabric; determine the threading area of the guide needle according to the half width and lateral density of the fabric; Select the double-needle bed model for the number of bars required; figure 1 As shown; when the bar traverse mechanism is on the right side, the number of yarn guide needle laying yarns is as follows:

[0037] GB 1: 2-0, 2-2 / 4-6, 4-4 / /

[0038] GB 2: 2-4, 2-2 / 2-0, 2-2 / /

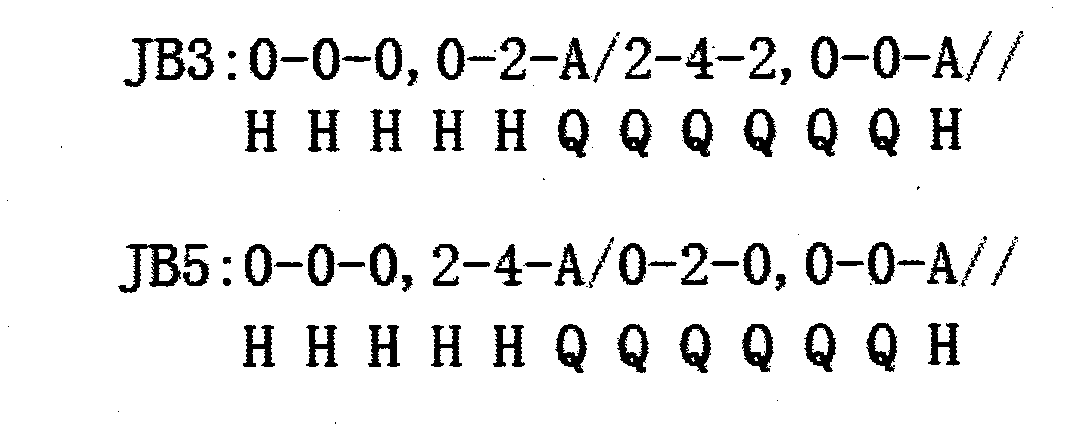

[0039] J B 3: 0-0-0, 0-2-A / 2-4-2, 0-0-A / /

[0040] GB4: 0-2, 0-0 / 0-0, 0-2 / /

[0041] J B 5: 0-0-0, 2-4-A / 0-2-0, 0-0-A / /

[0042] GB 6: 2-2, 2-0 / 0-0, 2-4 / /

[0043] GB 7: 2-2, ...

Embodiment 2

[0054] The production process is: process design of chain-knitting weft-inserted cylindrical hexagonal mesh fabric—yarn preparation—configuration of swing guide needles—arrangement of yarn guide needle control information—machine process adjustment and weaving—fabric finishing:

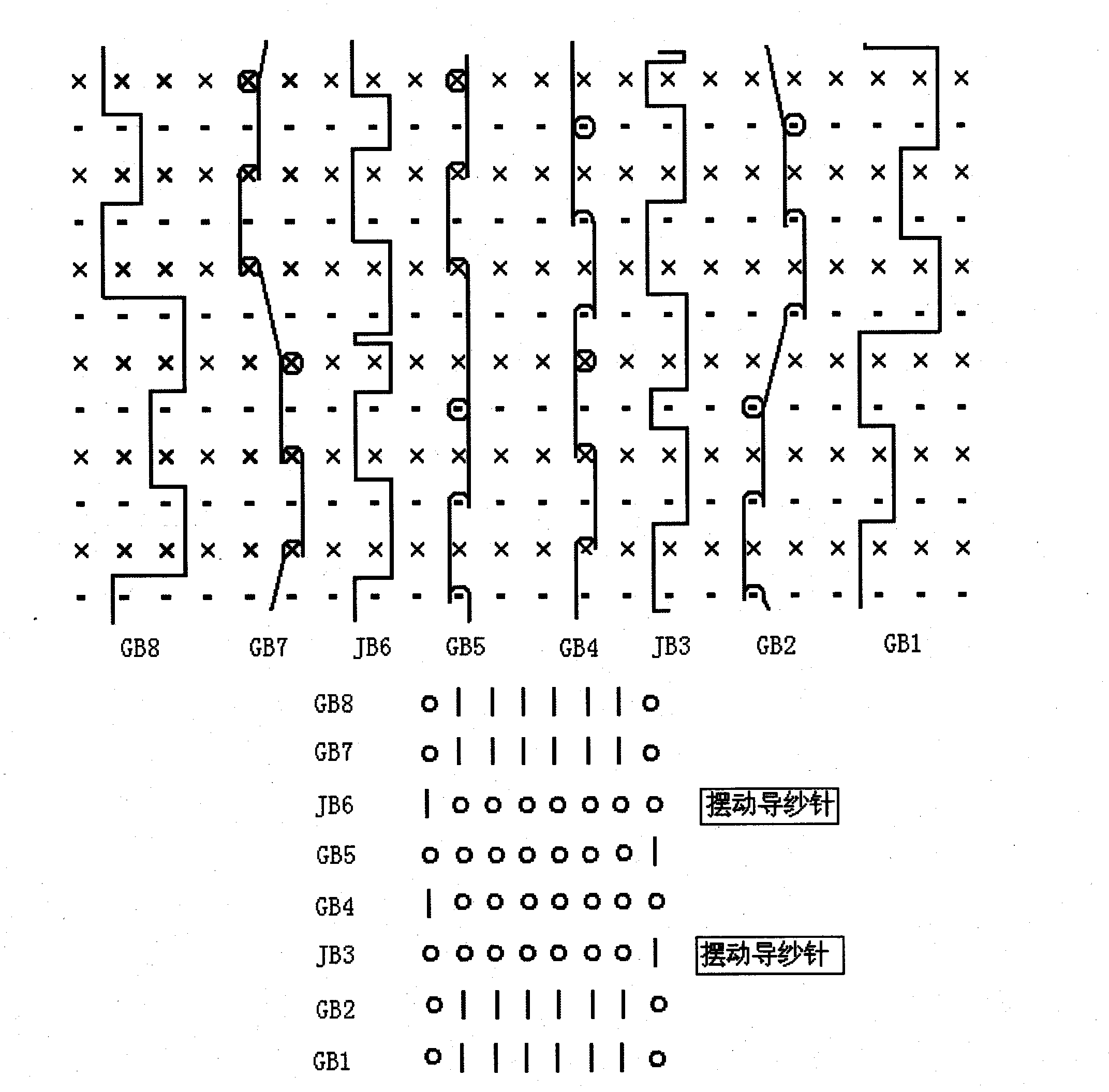

[0055] The process design of the chain weft-inserted cylindrical hexagonal mesh fabric is as follows: select suitable warp yarn raw materials according to the use of the chain weft-inserted cylindrical fabric; area; select the double-needle bed model according to the fineness of the warp raw material, the mesh size and the number of bars required; image 3 As shown; when the bar traverse mechanism is on the right side, the number of yarn guide needle laying yarns is as follows:

[0056] GB 1: 4-4, 4-4 / 2-2, 2-2 / 4-4, 4-4 / 0-0, 0-0 / 2-2, 2-2 / 0-0, 0-0 / /

[0057] GB 2: 2-4, 4-4 / 4-2, 2-2 / 2-4, 2-2 / 2-0, 0-0 / 0-2, 2-2 / 2-0, 2-2 / /

[0058] J B 3: 2-2-2, 2-2-2 / 0-0-0, 0-0-0 / 2-2-A, 0-0-0 / 0-0-0, 2-2-2 / 2-2-2,0-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com