Double-layer flexible windproof net

A windproof net and flexible technology, applied in the field of windproof net, can solve the problems of easily damaged columns, large wind resistance of columns, and inability to guarantee the safe operation of vehicles, so as to enhance the windproof effect and save material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

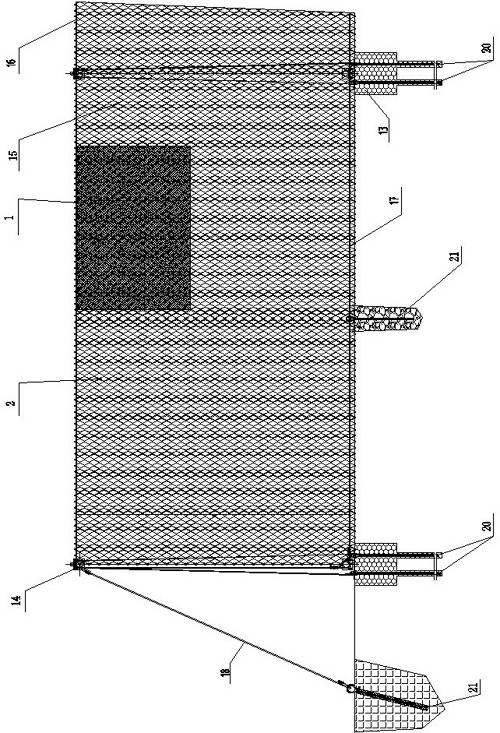

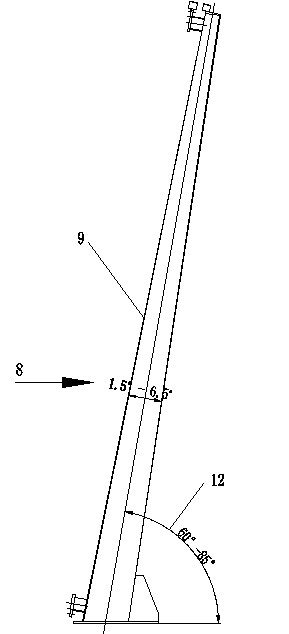

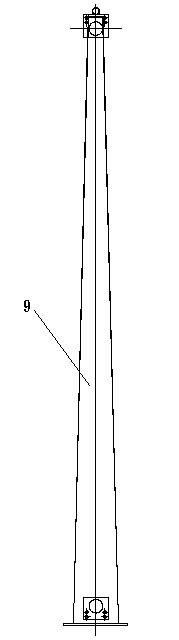

[0063] Refer to the attached figure 1 , the present invention discloses a double-layer flexible windproof net, comprising a column structure 14 and a net body structure 15 installed on the column structure 14, the column structure 14 is installed on a steel column foundation 13, and the steel column foundation 13 blocks along the area to be protected. The wind route is arranged at an interval of 5-12m, and an upper support rope 16 and a lower support rope 17 are connected between a plurality of column structures 14. The column structure 14 includes a rod body 9, and the rod body 9 is a tapered rod body structure with a small upper part and a larger lower part. The longitudinal section of the tapered rod body is an isosceles trapezoid, the upper bottom of the isosceles trapezoid is smaller than the lower bottom, and the cross section of the tapered rod body is a regular polygon; the mesh structure 15 is a two-layer structure, which is arranged in sequence along the wind directio...

Embodiment 2

[0067] On the basis of Example 1, the best implementation mode of the present invention is: the bottom end 11 of the tapered rod body is fixed on the steel column foundation 13, and the top end 10 of the tapered rod body is arranged obliquely toward the wind direction 8 . The inclination angle of the tapered rod body is 60-85 degrees. The diameter of the inscribed circle of the top 10 regular polygons of the tapered rod body is ∮80mm˜∮200 mm. The diameter of the inscribed circle of the regular polygon at the bottom end 11 of the tapered rod body is ∮200mm˜∮500 mm. The support net 2 is formed by a plurality of diamond-shaped grid units woven by steel wires or steel wire ropes, the diameter of the inscribed circle of the grid is ∮50 mm to ∮300 mm, and the diameter of the steel wires or steel wire ropes is ∮3 mm to ∮8 mm. The windproof net 1 is formed by a plurality of rhombic grid units woven by steel plates or steel wires, the diameter of the inscribed circle of the grid is ∮3...

Embodiment 3

[0069] Windproof net 1 is mainly composed of: conical steel column, flexible support protection net, small aperture blocking protection net, upper and lower support ropes 17, side stay ropes 18, back stay rope 19, anchor bolts and anchors 20, pull anchors and anchors, clips components etc. The layout is that the steel column foundation 13 is arranged at a distance of 5-10 meters along the direction of the wind-blocking route in the area to be protected (the specific distance is determined according to the wind speed of the protected area and the height to be protected). After the steel column foundation 13 is fabricated + install the steel column on the foundation Stand it up and hang the support rope on the steel column hanger. Install the upper side stay rope 18 and the back stay rope 19 and tighten up the steel column that needs to install the back stay rope 19 and the side stay rope 18. Hang the flexible support windproof net 1 on the support rope and sew them together, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inscribed circle diameter | aaaaa | aaaaa |

| Inscribed circle diameter | aaaaa | aaaaa |

| Inscribed circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com