Web beam, preparation method thereof, and overhead structure used for CSI dwelling house and formed by web beam

A web and plate beam technology, applied in the field of CSI residential overhead structure, can solve the problems of not considering pipeline layout, high engineering cost, and large amount of steel, and achieve the effects of material saving, convenient construction and good mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

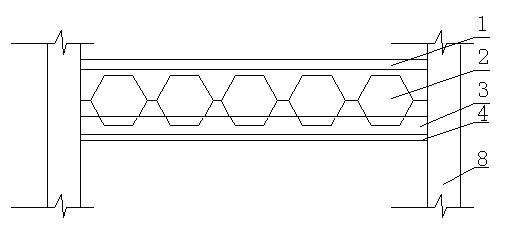

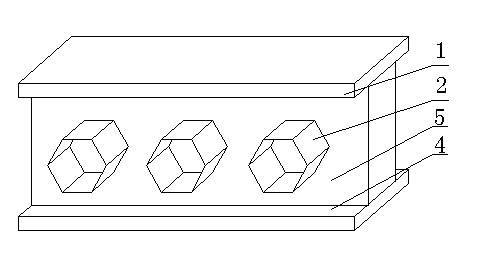

[0032] Reference attached figure 1 , 2 , a web beam, comprising an upper flange plate 1, a lower flange plate 4 and a web 5, the upper flange plate 1 is affixed to the upper end surface of the web plate 5, and the lower wing is affixed to the lower end surface of the web plate 5 The edge plate 4 and the web plate 5 are uniformly or unevenly provided with a plurality of threading holes 2 along the length direction.

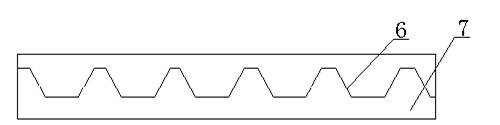

[0033] In practice, considering the convenience of processing and material saving, the web is divided into an upper web 5-1 and a lower web 5-2, the upper web 5-1 is provided with upper teeth a, and the corresponding position of the lower web 5-2 is provided with The lower teeth b, upper teeth a and lower teeth b are fixed to form threading holes 2, and the shape and size of each threading hole 2 formed after the upper teeth a of the upper web 5-1 and the lower teeth b of the lower web 5-2 are fixed Similarly, the threading holes 2 formed after the upper teeth a ...

Embodiment 2

[0038] combined with Figure 6 , 7 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that the threading hole 2 is circular. Reference attached Figure 8 , the preparation method of the web beam described in this embodiment, the tooth-shaped cutting line 6 is arc-shaped. Other compositions and connections and preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com