Electromagnetic lock positioning plate for high-voltage switch equipment and production method of electromagnetic lock positioning plate

A high-voltage switch and electromagnetic lock technology, which is applied to building locks, building structures, and locks controlled by non-mechanical transmissions, can solve the problems of rising electromagnetic lock costs, high manufacturing costs, and large capital occupation, so as to reduce manufacturing costs, The effect of simple and mature process and high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

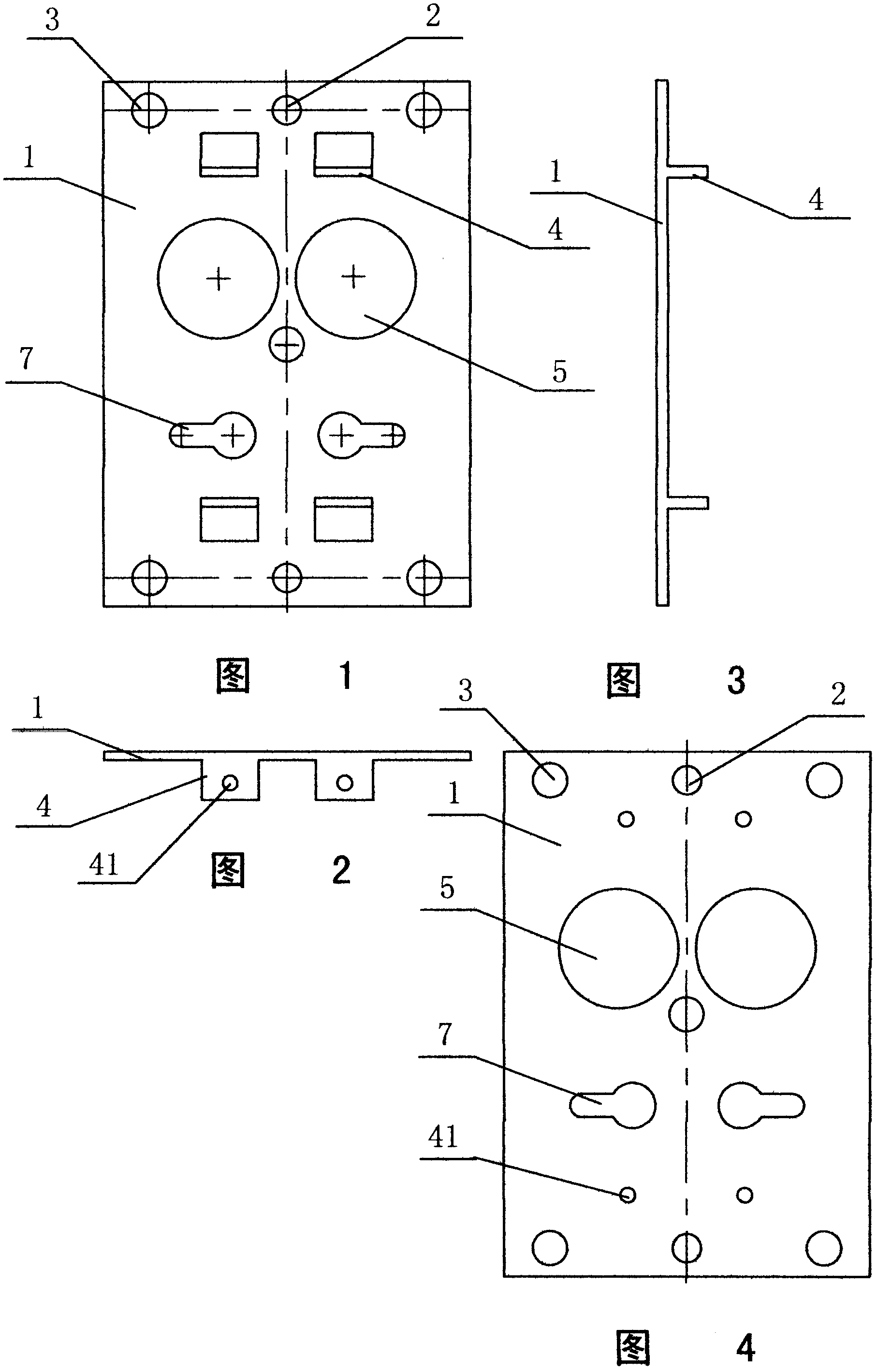

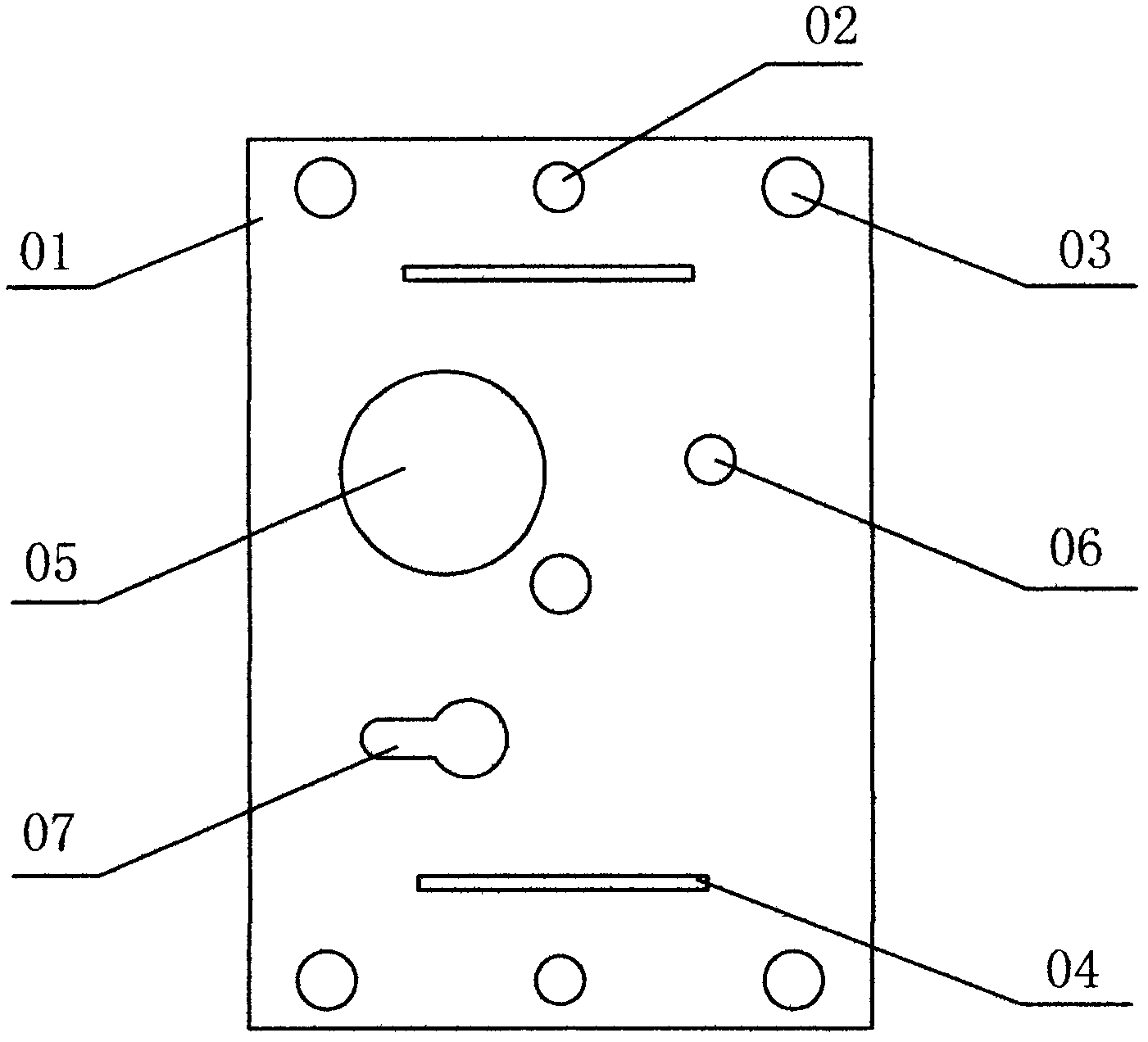

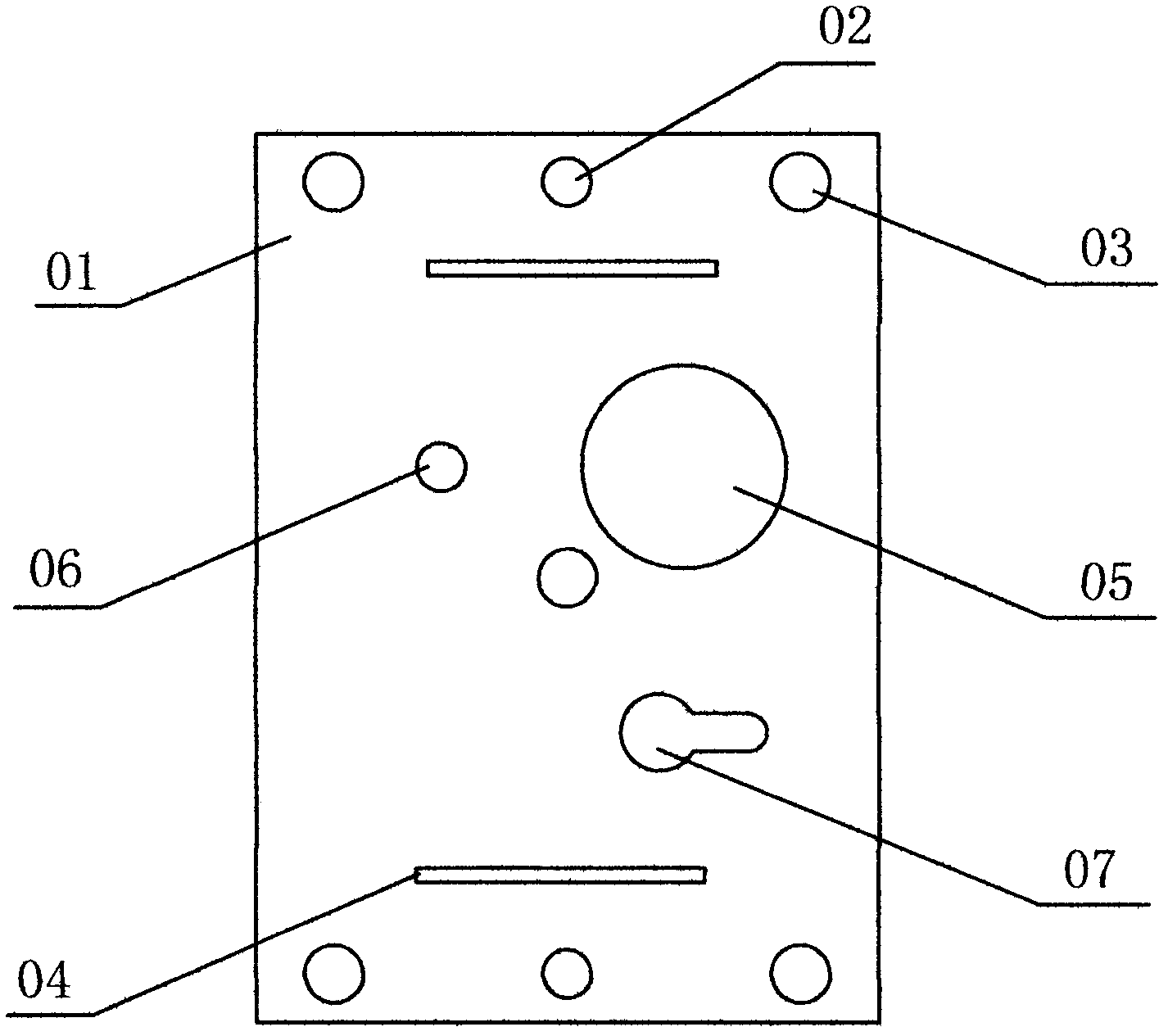

[0025] Below in conjunction with accompanying drawing the implementation details of the present invention are described as follows:

[0026] like figure 1 , 2 . As shown in 3, an electromagnetic locking bit plate for high-voltage switchgear, including a rectangular plate body 1, is located at the upper and lower midpoints of the upper and lower sides of the plate body, and has a screw hole 2 for installing a whole lock, located at the plate body The 4 and 1 connection electromagnetic lock panels at the four corners and the center are embedded holes 3, which are characterized in that the connecting line between the midpoints of the upper and lower sides of the board is the symmetrical axis, and there are two symmetrically distributed ones.

[0027] ——The upper and lower positioning connecting plates 4 perpendicular to the surface of the plate body for connecting the electromagnetic lock housing;

[0028] ——The positioning circular hole 5 corresponding to the handle hole or t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap