Connecting pipe structure, four-way reversing valve and air conditioner

A technology of taking over structure and copper pipe, applied in the direction of valve shell structure, valve device, valve details, etc., can solve the problems of low welding quality, can not well meet the working requirements of four-way directional valve, etc., to ensure the welding quality , Solve welding difficulties and improve the effect of welding air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

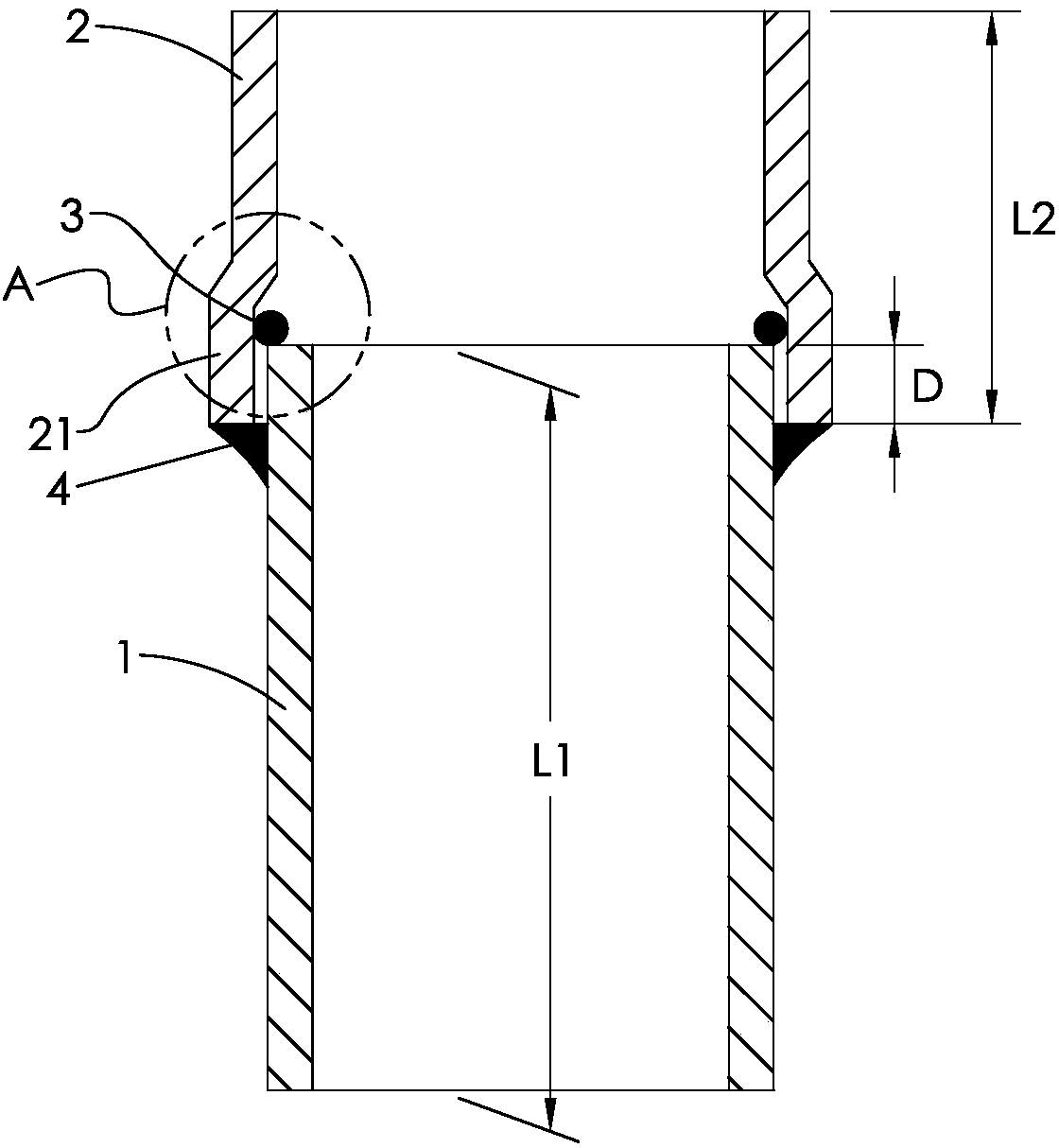

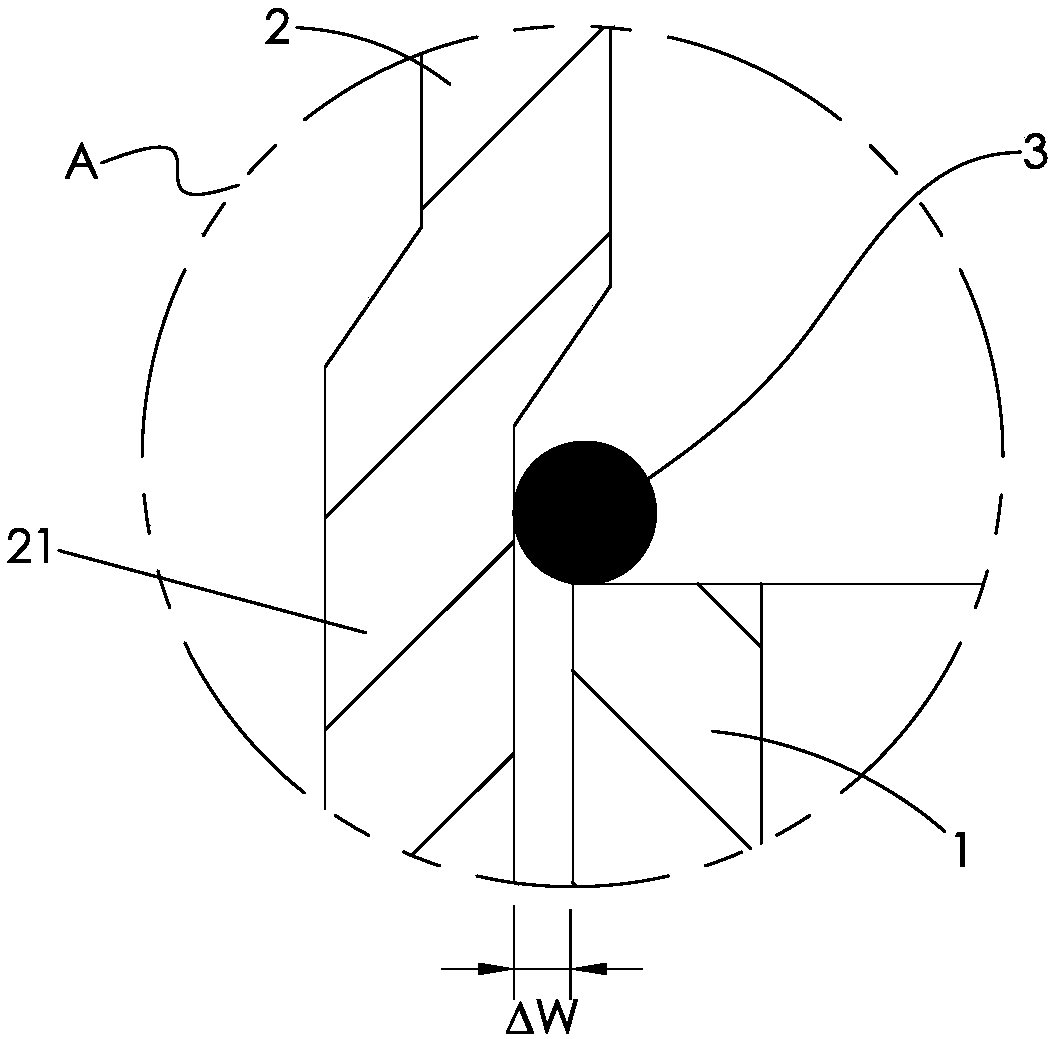

[0033] like figure 1 As shown, the connecting pipe structure provided by Embodiment 1 of the present invention includes an axially hollow steel pipe 1 and a copper pipe 2, the front end of the steel pipe 1 is inserted into the rear end of the copper pipe 2, the front end of the copper pipe exceeds the front end of the steel pipe, and the steel pipe It is fixed by welding with the copper pipe. The rear end surface of the copper pipe 2 and the outer wall of the steel pipe 1 are fixed by fusion welding, and the front end surface of the steel pipe 1 and the inner wall of the copper pipe 2 are fixed by brazing, and the solder 3 used for brazing is arranged at the front end of the steel pipe between the surface and the inner wall of the copper tube.

[0034] After melting, the solder 3 can effectively fill the gap between the steel pipe 1 and the copper pipe 2, thereby ensuring the airtightness of welding between the steel pipe and the copper pipe. The rear end of the copper pipe ...

Embodiment 2

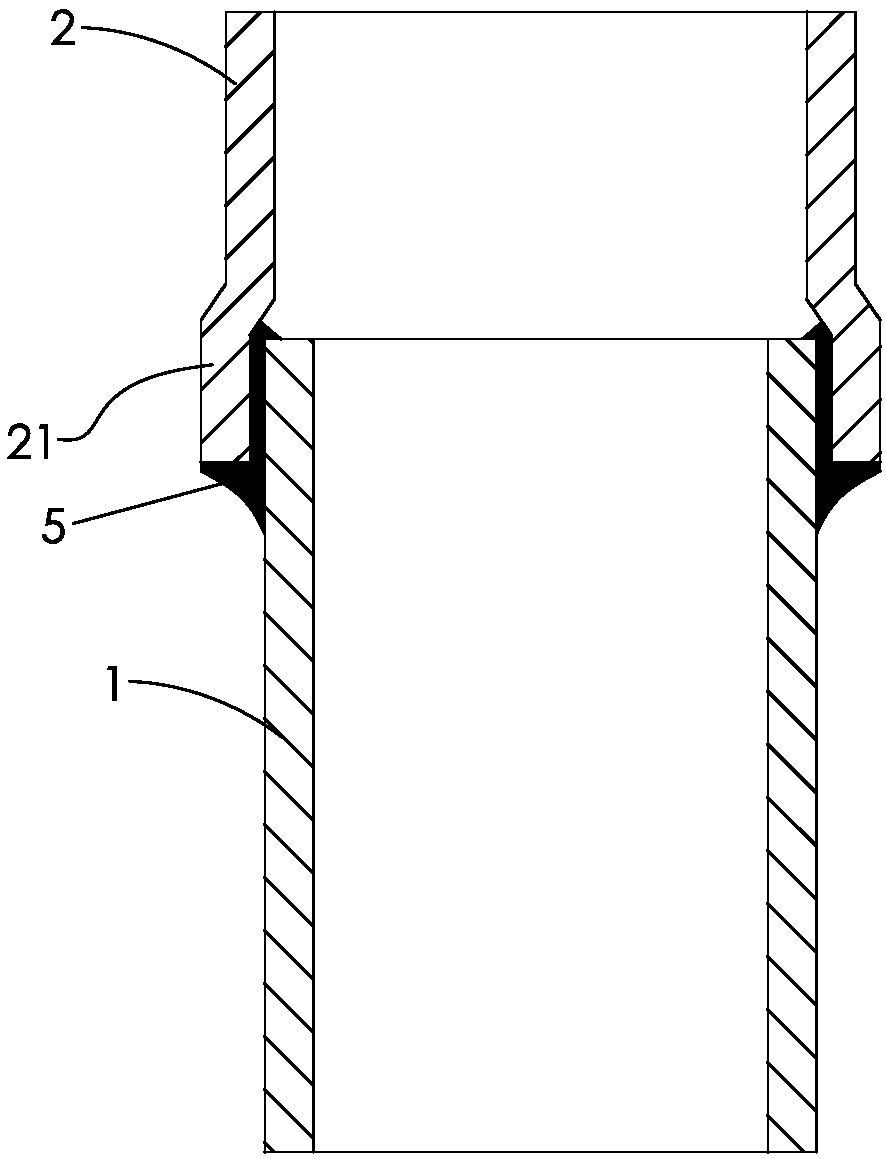

[0048] like Figure 4 As shown, the difference between Embodiment 2 of the present invention and Embodiment 1 above is that since the inner diameter of the copper pipe 2 is greater than the outer diameter of the steel pipe 1, in order to insert the front end of the steel pipe into the copper pipe to meet the requirements of the welding gap, the copper pipe 2 The necking section 22 is formed at the rear end after the necking process, and the necking section is the positioning part.

[0049] like Figure 5 As shown, after the welding is completed, the brazing filler metal 3 and the welding seam 4 are combined to form a weld seam 5 to realize the welding and fixing between the steel pipe 1 and the copper pipe 2 .

[0050] The other structures of the second embodiment are the same as those of the first embodiment above, and will not be repeated here.

Embodiment 3

[0052] like Figure 6 As shown, the difference between the third embodiment of the present invention and the first embodiment above is that the rear end of the copper pipe 2 matches the front end of the steel pipe 1, and the circumferential direction of the copper pipe is provided with a Between the positioning concave ring 23, the positioning concave ring is the positioning part.

[0053] In this embodiment, the cross-sectional shape of one side of the positioning concave ring 23 along the axial direction is arc-shaped, and the solder 3 is placed between the positioning concave ring 23 and the front end surface of the steel pipe 1 .

[0054] like Figure 7 As shown, after the welding is completed, the brazing filler metal 3 and the welding seam 4 are combined to form a weld seam 5 to realize the welding and fixing between the steel pipe 1 and the copper pipe 2 .

[0055] The other structures of the third embodiment are the same as those of the first embodiment above, and wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com