Device for machining hole

A technology for processing holes and processing systems, applied in the field of mechanical processing and manufacturing, can solve the problems that the dimensional accuracy and roughness requirements of finished holes cannot be effectively guaranteed, and the high rejection rate of boring holes, so as to improve the qualified rate of finished products and the quality of holes. The effect of roughness requirements, improving production efficiency, and increasing pull-off force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

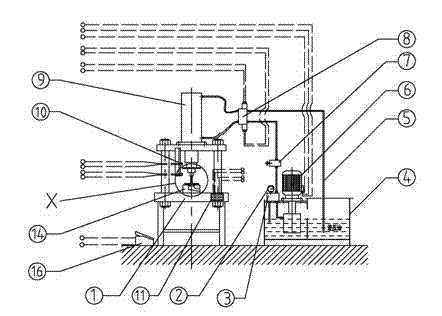

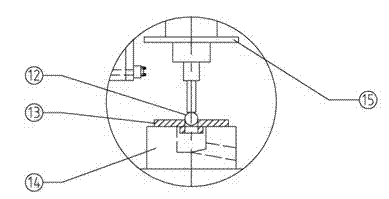

[0012] Embodiment: The device for processing holes in this embodiment is as attached figure 1 and 2 As shown, it mainly includes a hydraulic system, a control system and a processing system; the processing system includes steel balls 12 matching the hole diameter of the workpiece 13, and the hydraulic system processes the holes on the workpiece 13 by squeezing the steel balls 12.

[0013] In the embodiment, the hydraulic system includes an oil cylinder 4, an oil pipe 5, a pressure gauge 2, an electric motor, an oil pump and a filter 6, a throttle valve 7, an overflow valve 3, a three-position four-way solenoid valve 8 and a hydraulic cylinder piston 9; The system includes a travel switch 10 , a button 11 and a foot switch 16 .

[0014] The processing system comprises a base 1, on which there is a spacer 14, a workpiece 13, a steel ball of fixed size 12 and a travel switch block 15.

[0015] The workpiece 13 of this embodiment is an automobile water pump flange. During proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com