Automobile air-conditioning compressor swash plate and production method thereof

A technology for automotive air conditioners and compressors, applied in the field of auto parts, can solve the problems of poor high temperature strength and high temperature hardness, product internal stress, low dimensional machining accuracy, etc., to improve wear resistance and strength, avoid deformation and jam, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

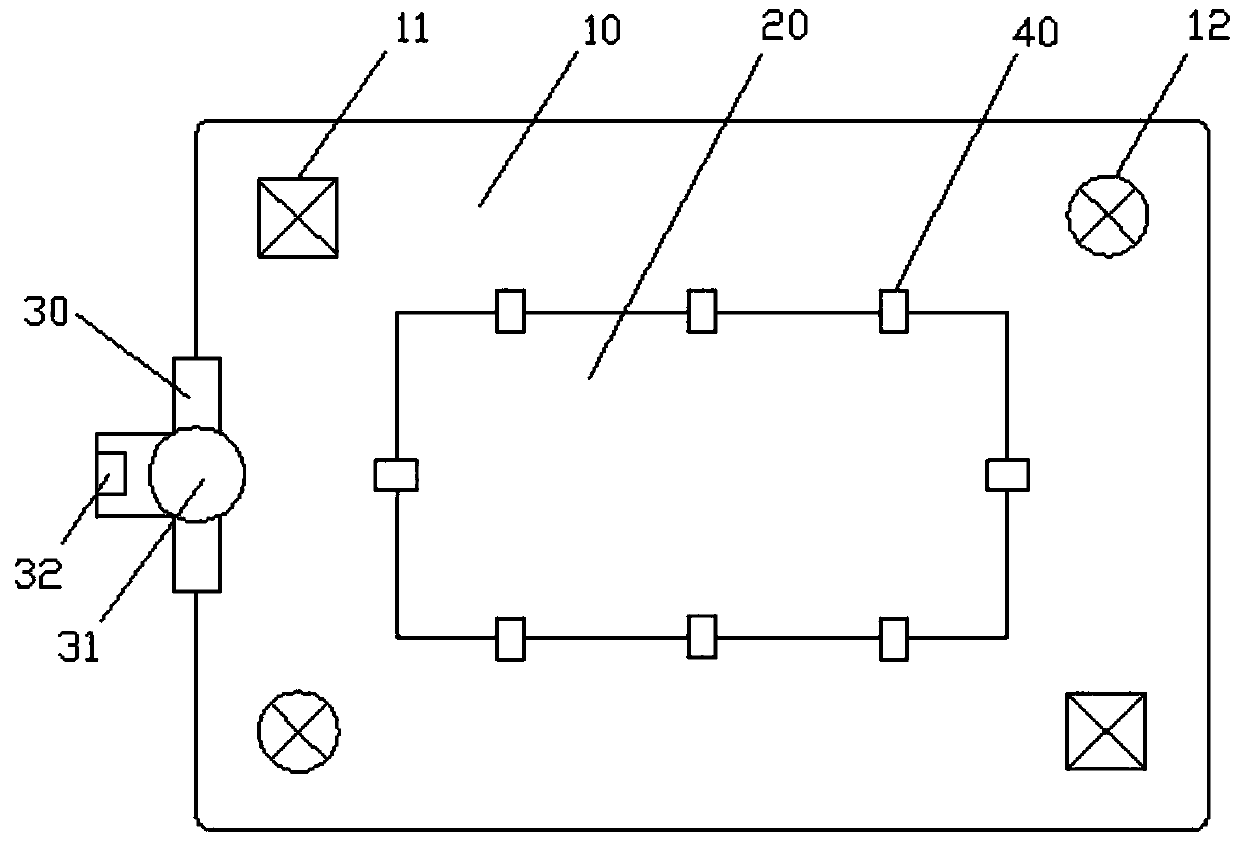

[0027] like figure 1 Shown is a car air-conditioning compressor swash plate according to the present invention, said swash plate is made of aluminum alloy comprising the following components by weight percentage: silicon: 10%; copper: 3%; magnesium: 0.2%; Nickel: 0.6; Manganese: 0; Molybdenum: 0.2%; Iron: 0; Zinc: 0; Chromium: 0.2%; Titanium: 0; Carbon: 0.1%; Rhenium: 0.2%; the balance is aluminum.

[0028] Further, the composition of the swash plate also includes powder lubricant, and the weight percentage of the powder lubricant is ≤0.1%.

[0029] Further, the weight percentage of silicon is 10.5%, the weight percentage of magnesium is 0.22%, the weight percentage of nickel is 0.8%, the weight percentage of molybdenum is 0.25%, the weight percentage of chromium is 0.3%, and the weight percentage of carbon is 0.12% %, the weight percentage of rhenium is 0.25%.

[0030] Specifically, the production method of the swash plate of the automobile air-conditioning compressor inclu...

Embodiment 2

[0046] like figure 1 Shown is a swash plate of an automobile air-conditioning compressor according to the present invention, and the swash plate is made of an aluminum alloy comprising the following components by weight percentage: silicon: 12%; copper: 4%; magnesium: 0.3%; Nickel: 1.2%; manganese: 0.2%; molybdenum: 0.4%; iron: 0.4%; zinc: 0.1%; chromium: 0.6%; titanium: 0.2%; carbon: 0.2%; rhenium: 0.4%; balance aluminum.

[0047] Further, the composition of the swash plate also includes powder lubricant, and the weight percentage of the powder lubricant is ≤0.1%.

[0048] Further, the weight percentage of silicon is 11.5%, the weight percentage of magnesium is 0.28%, the weight percentage of nickel is 1.0%, the weight percentage of molybdenum is 0.35%, the weight percentage of chromium is 0.5%, and the weight percentage of carbon is 0.18% , The weight percent of rhenium is 0.35%.

[0049] Specifically, the production method of the swash plate of the automobile air-conditio...

Embodiment 3

[0065] like figure 1 As shown, it is a swash plate of an automobile air-conditioning compressor according to the present invention, and the swash plate is made of aluminum alloy comprising the following components by weight percentage: silicon: 11%; copper: 3.5%; magnesium: 0.25%; Nickel: 0.9%; manganese: 0.1%; molybdenum: 0.3%; iron: 0.2%; zinc: 0.05%; chromium: 0.4%; titanium: 0.1%; carbon: 0.15%; rhenium: 0.3%; balance aluminum.

[0066] Further, the composition of the swash plate also includes powder lubricant, and the weight percentage of the powder lubricant is ≤0.1%.

[0067] Further, the weight percentage of silicon is 11%, the weight percentage of magnesium is 0.25%, the weight percentage of nickel is 0.9%, the weight percentage of molybdenum is 0.3%, the weight percentage of chromium is 0.4%, and the weight percentage of carbon is 0.15% , the weight percentage of rhenium is 0.3%.

[0068] Specifically, the production method of the swash plate of the automobile air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com