External dynamic test cylinder of sensor

A dynamic test cylinder, external technology, applied in the fluid pressure actuation system test, fluid pressure actuation device, mechanical equipment and other directions, can solve the problems of difficult maintenance, high price, difficult manufacturing, etc., to achieve convenient installation, commissioning and maintenance , good practicability, moderate test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

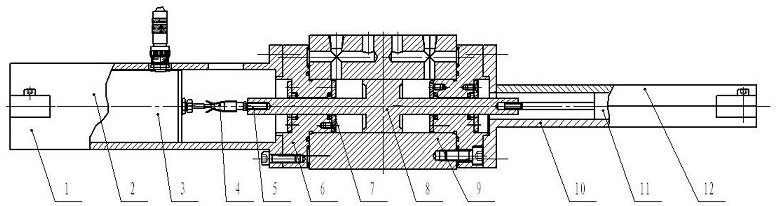

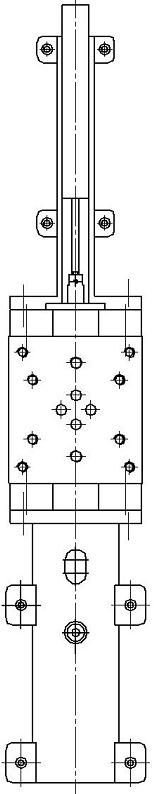

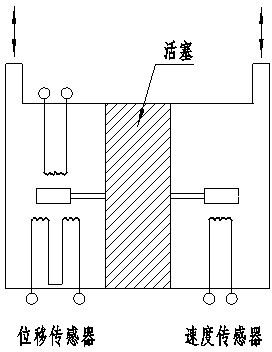

[0021] The present invention is specifically described in conjunction with accompanying drawing, as figure 1 -Shown in 2, the overall structure of the device is mainly composed of three parts: dynamic cylinder, speed sensor 3 and displacement sensor 11;

[0022] Described dynamic cylinder is made up of piston 8, cylinder body 9 and the end cover 6 of cylinder body 9 both sides; The lower end cover 1 of the sensor is connected by screws, the moving rod of the speed sensor 3 is connected with the connecting screw 5 installed on the guide rod of the piston 8 through the connecting clip 4, and the speed sensor 3 is fixed on one side of the dynamic cylinder; the displacement sensor 11 is freely assembled on the lower end cover 10 of the displacement sensor, the upper end cover 12 of the displacement sensor is connected with the lower end cover 10 of the displacement sensor by screws, the iron core of the displacement sensor 11 is connected with the guide rod of the piston 8 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com