Vertical water-cooling double-cylinder type permanent magnet speed regulator

A permanent magnet speed governor, double-barrel technology, applied in the direction of permanent magnet clutch/brake, cooling/ventilation device, electric brake/clutch, etc. Equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

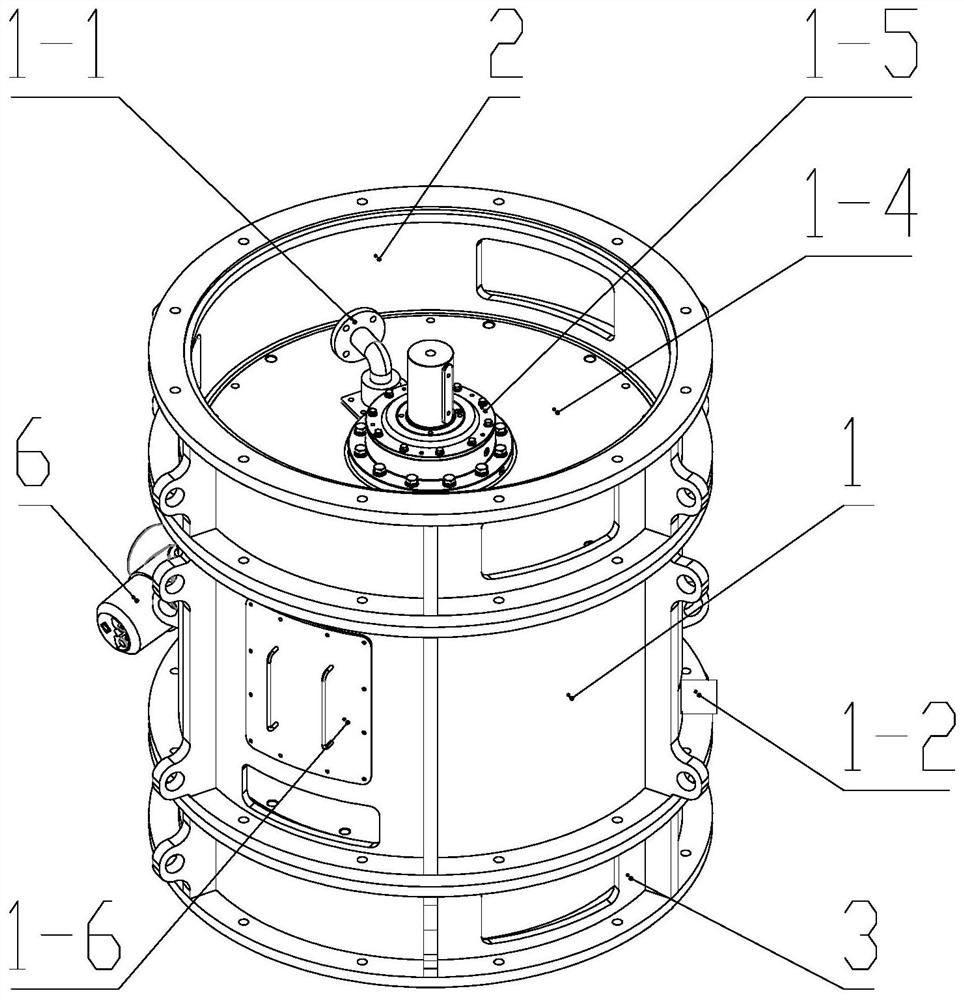

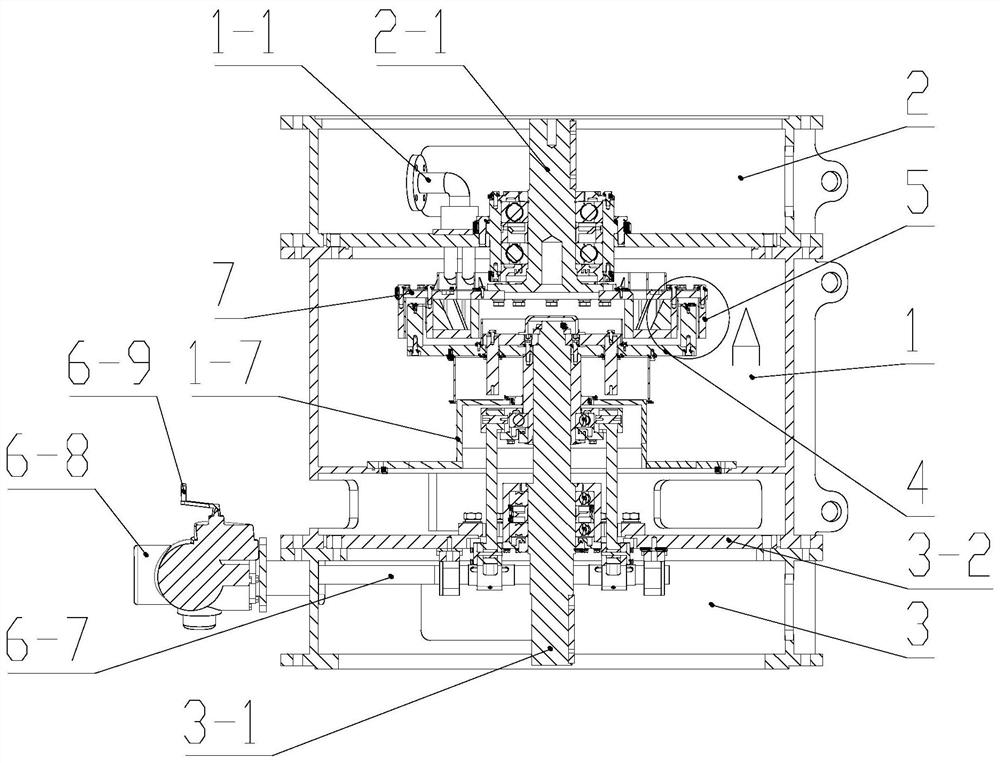

[0042] see Figure 1 to Figure 7, the present invention provides a vertical water-cooled double-tube permanent magnet governor, including a vertical cooling tube 1, the inside of the cooling tube 1 is hollow, the upper end of the cooling tube 1 is fixedly connected to the input support tube 2, and the lower end of the cooling tube 1 A load support cylinder 3 is provided, which also includes a permanent magnet rotor assembly 4 and a conductor rotor assembly 5 arranged inside the cooling cylinder 1. The permanent magnet rotor assembly 4 is fixedly connected to the load shaft 3-1, and the load shaft 3-1 is connected to the cooling cylinder 1. The lower end is rotationally connected; the conductor rotor assembly 5 is fixedly connected to the input shaft 2-1, and the input shaft 2-1 is rotationally connected to the upper end of the support cylinder;

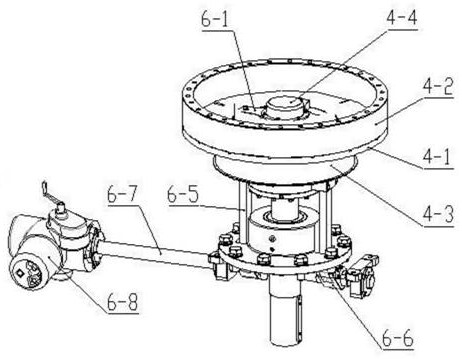

[0043] It also includes an adjustment mechanism 6 for adjusting the axial movement of the permanent magnet rotor assembly 4 along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com