Conveying roller way and conveying method for centering and splicing steel structural components

A technology of conveying roller table and steel structure, which is applied in the direction of roller table, conveyor, conveyor objects, etc., can solve the problems of increasing labor cost, reducing operation efficiency and safety, and low degree of automation, and achieves convenient installation, commissioning and maintenance , Improve operational safety and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

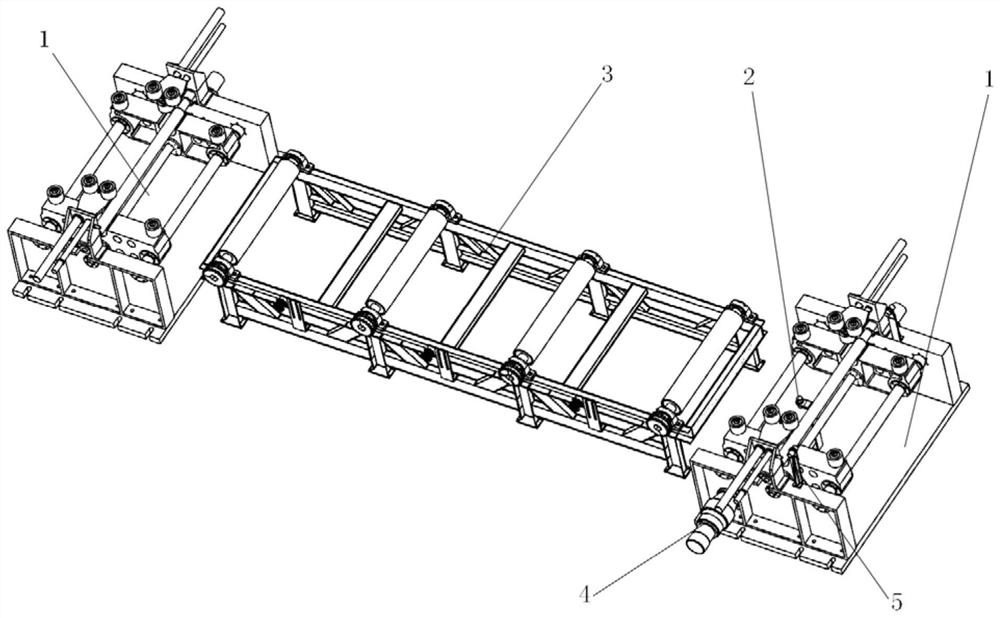

[0055] Example 1: see attached Figure 1-6 , a conveying roller table for centering and splicing of steel structural components, comprising a conveying roller table 3 and two centering and centralizing devices 1; the two centering and centering devices 1 are respectively arranged at the front and rear ends of the conveying roller table 3; The centering and centering device 1 at the front end of the conveying roller table 3 is equipped with a conveying roller table power part 4, a web incoming material sensor 5 and a wing plate incoming material sensor 2; the conveying roller table power part 4 drives the conveying roller through the roller table active chain 405. The conveying roller 302 on the lane 3 rotates;

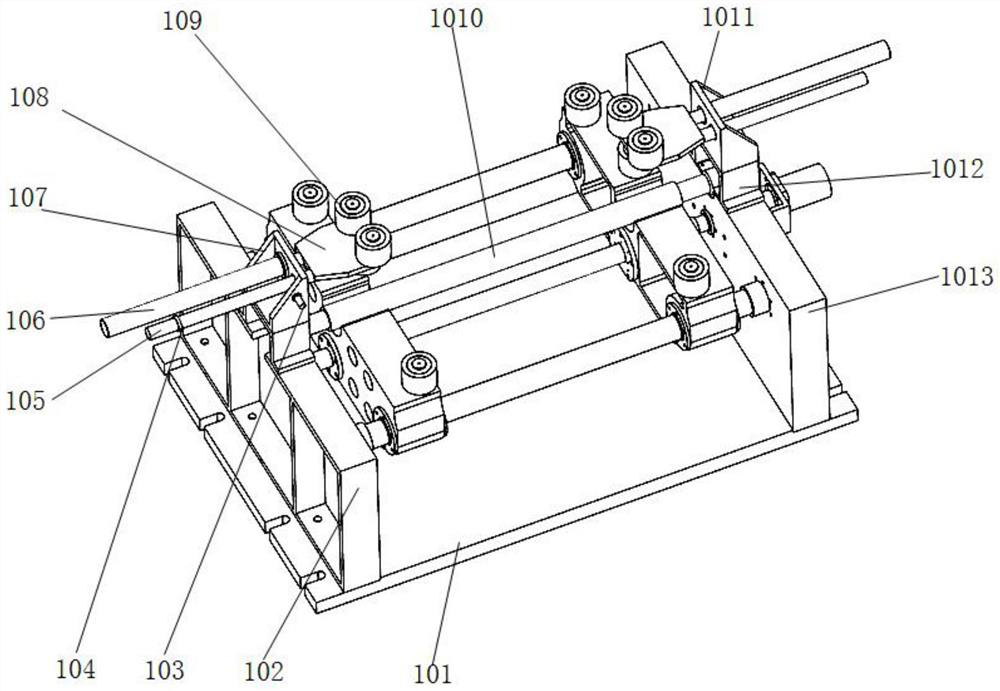

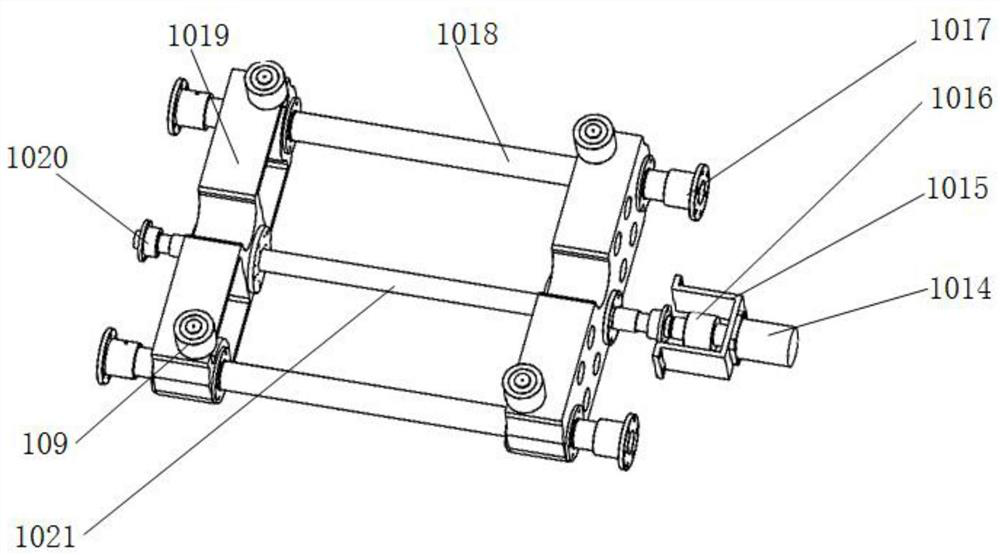

[0056] The centering and centering device 1 includes a base 101 on which a left support seat 102 and a right support seat 1013 are installed, a web centering device and a wing plate centering device; the wing plate is installed on the base 101 at the front end of the c...

Embodiment 2

[0066] Example 2: see attached Figure 1-7 , a conveying method using a conveying roller table for centering and splicing of steel structural members, using the conveying roller table in Example 1, comprising the following steps:

[0067] Step 1, wing plate righting: reset the system, hoist the wing plate on the conveying roller 3, the wing plate incoming sensor detects the incoming material from 2, and after the time set by the delay is reached, the wing plate centering motor 1014 is started, and the wing plate is dragged The centering and centering wheels 109 on the centering slide 1019 are simultaneously pressed against both sides of the wing plate, and when the torque sensor 1016 reaches the preset value, it means that the wing plate has been clamped, and the wing plate centering motor 1014 is stopped and maintained;

[0068] Step 2, web centering: hoist the web to the wing plate that has been centered on the conveying roller table 3, the web incoming sensor 5 detects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com