Tapping travel control mechanism for tapping equipment

A stroke control and equipment technology, which is applied in metal processing equipment, thread cutting machines, manufacturing tools, etc., can solve the problems of large space occupation, inability to use, complicated installation, etc., and achieves convenient installation, commissioning and maintenance, simple design and manufacture, and small occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

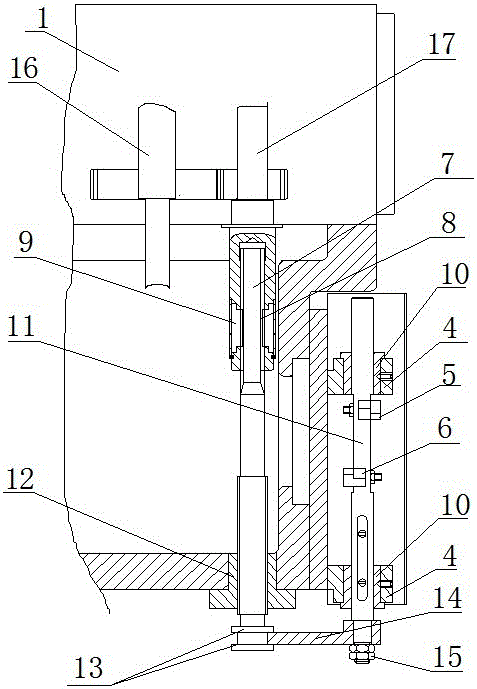

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

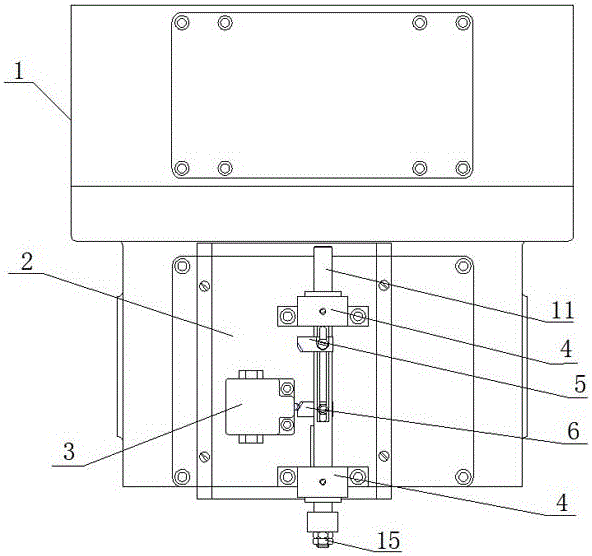

[0012] like figure 1 and figure 2 As shown, this embodiment includes a rod 11 , a cam bar 7 , a cam nut 12 , a connecting plate 14 , a travel switch 3 and a housing 2 . The housing 2 is fixed on one end of the spindle box 1, and one end thereof is connected with a rod 11 that can slide along the guide sleeve 10, and 4 is a guide sleeve bracket. In the spindle box 1, except each main shaft 16, there is also a transmission shaft 17, and the end that the transmission shaft 17 stretches out from the spindle box 1 is hollow. One end of the cam bar 7 is slidably connected in the hollow of the power transmission shaft 17, and its preferred structure is: at least one key 9 is fixed on the hollow inner wall of the power transmission shaft 17, and the relative position of the cam bar 7 is provided with a key corresponding to the key 9. Matching slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com