Four-level gear reducer with two shafts concentric

A technology of gear reducer and concentric shaft, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the problems of weight increase, reducer volume increase, complex structure, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

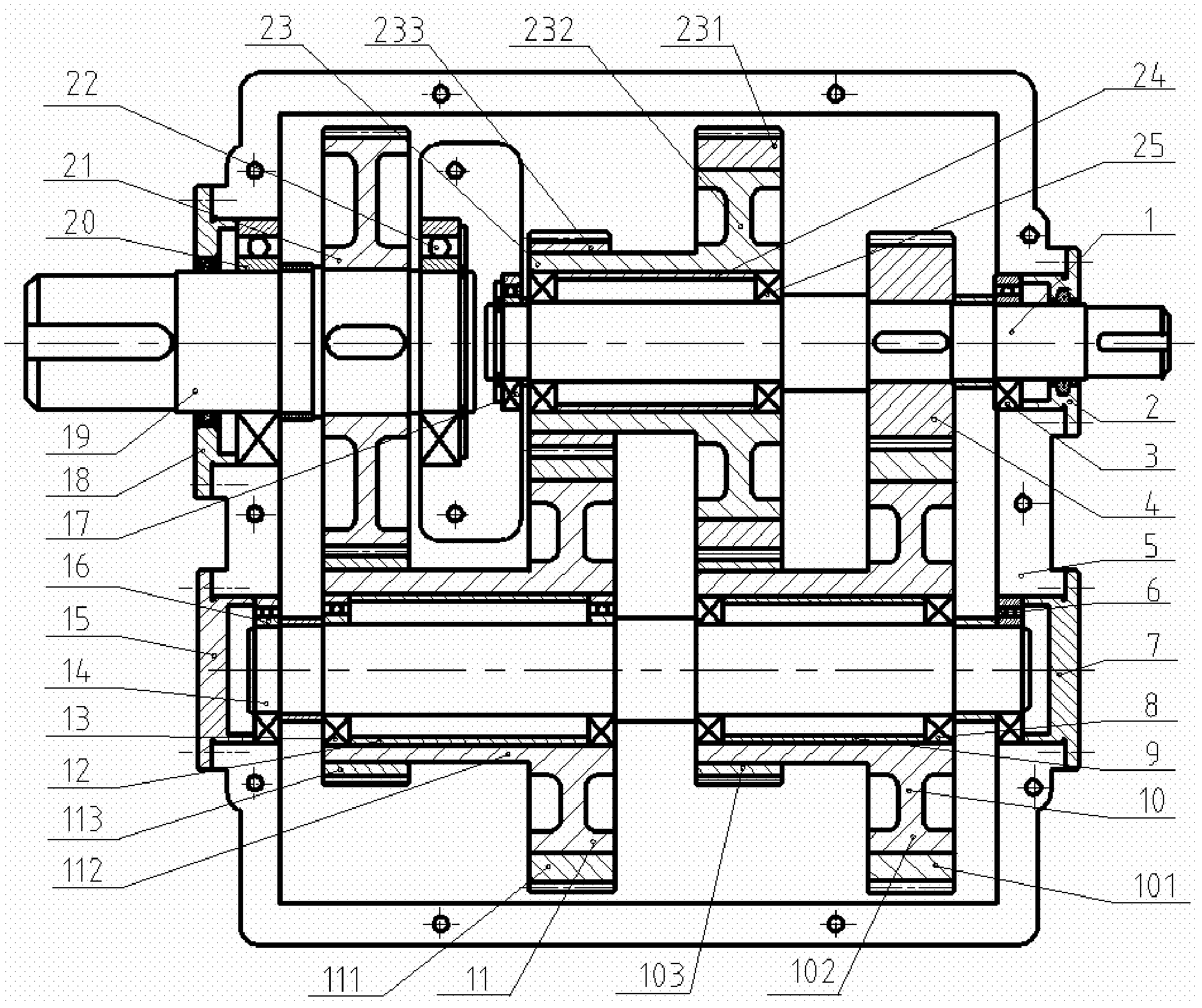

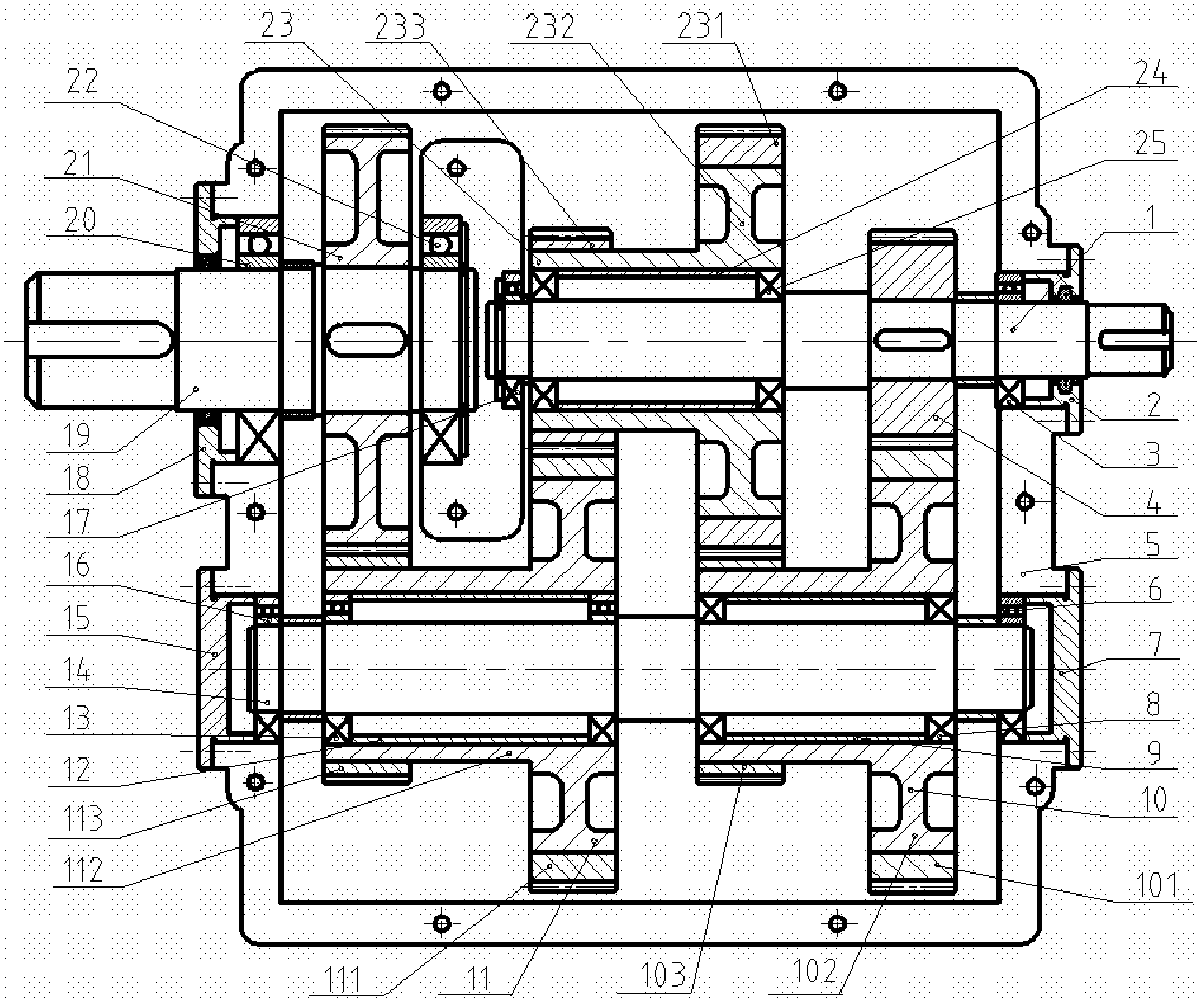

[0016] Such as figure 1 The shown four-stage gear reducer with two concentric shafts includes input shaft 1, input shaft through cover 2, input shaft bearing I3, input shaft gear 4, box body 5, intermediate shaft bearing I6, intermediate shaft end cover I7, Double gear I bearing 8, double gear I bearing sleeve 9, double gear I10, double gear II11, double gear II bearing sleeve 12, double gear II bearing 13, intermediate shaft 14, intermediate shaft end cover II15, intermediate shaft bearing II16, input shaft bearing II17, output shaft cover 18, output shaft 19, output shaft bearing II20, output shaft gear 21, output shaft bearing I 22, duplex gear III23, duplex gear III bearing sleeve 24. Duplex gear III bearing 25, characterized in that the input shaft 1 is supported on the box body 5 by the input shaft bearing I3 and the input shaft bearing II17, and the input end of the input shaft 1 is equipped with the input shaft through cover 2, the left The part is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com