Refrigeration cycle method and system for 70MPa hydrogen filling station

A circulation system and refrigeration cycle technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of no safe release pipeline, limited installation conditions, and defective safety performance in the cooling system, and achieve Optimizing energy consumption during the filling process, saving installation space, and flexible control of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

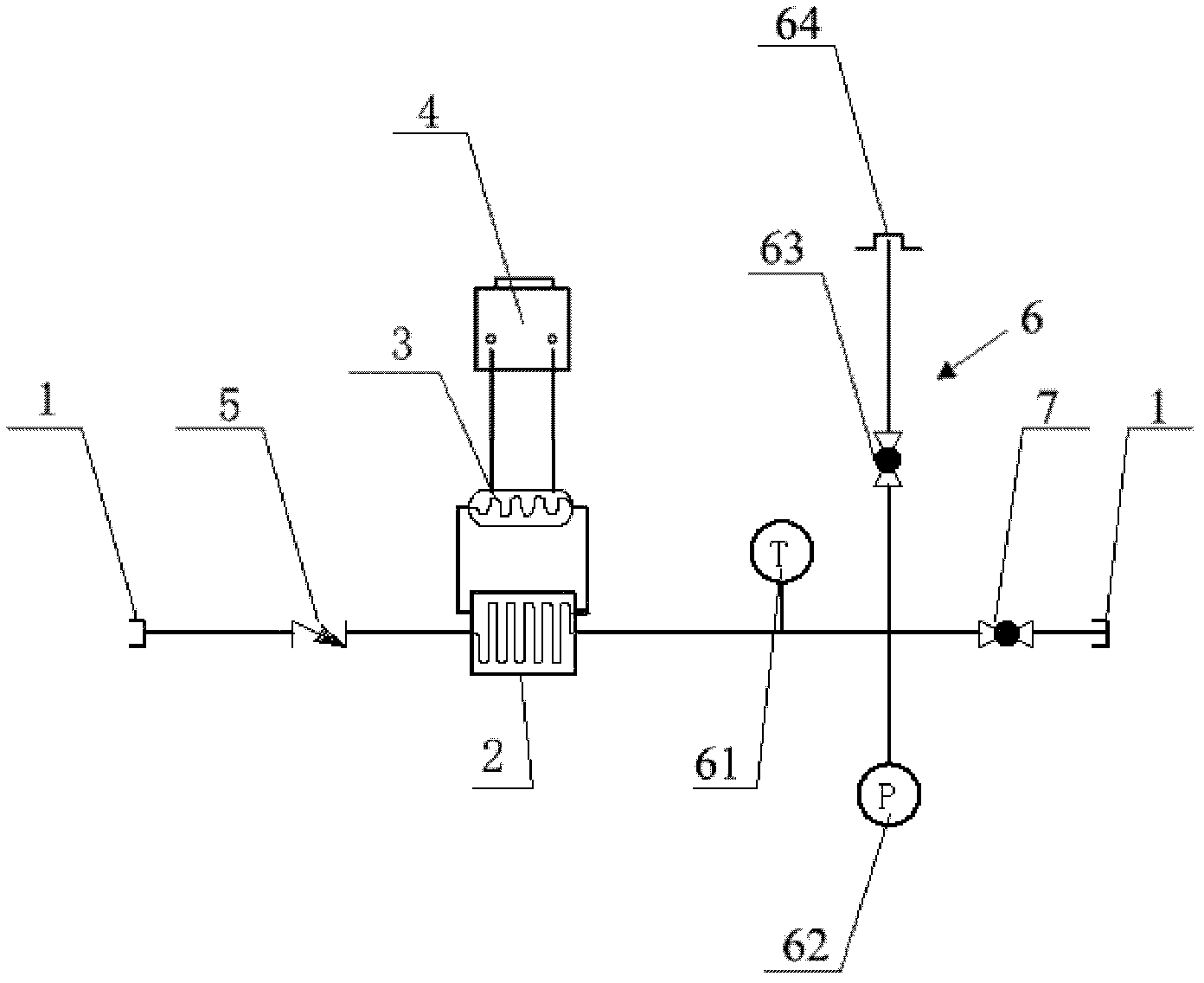

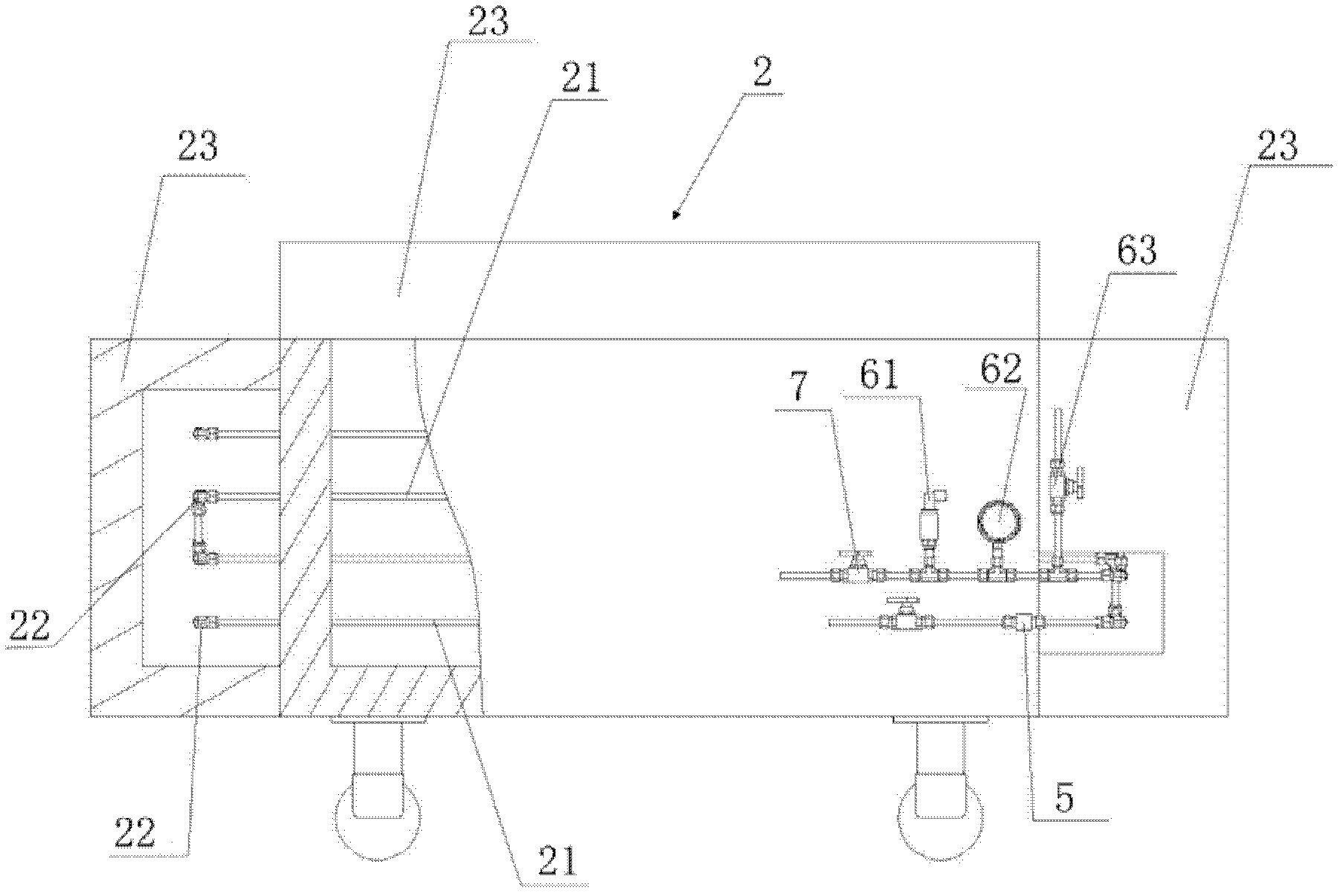

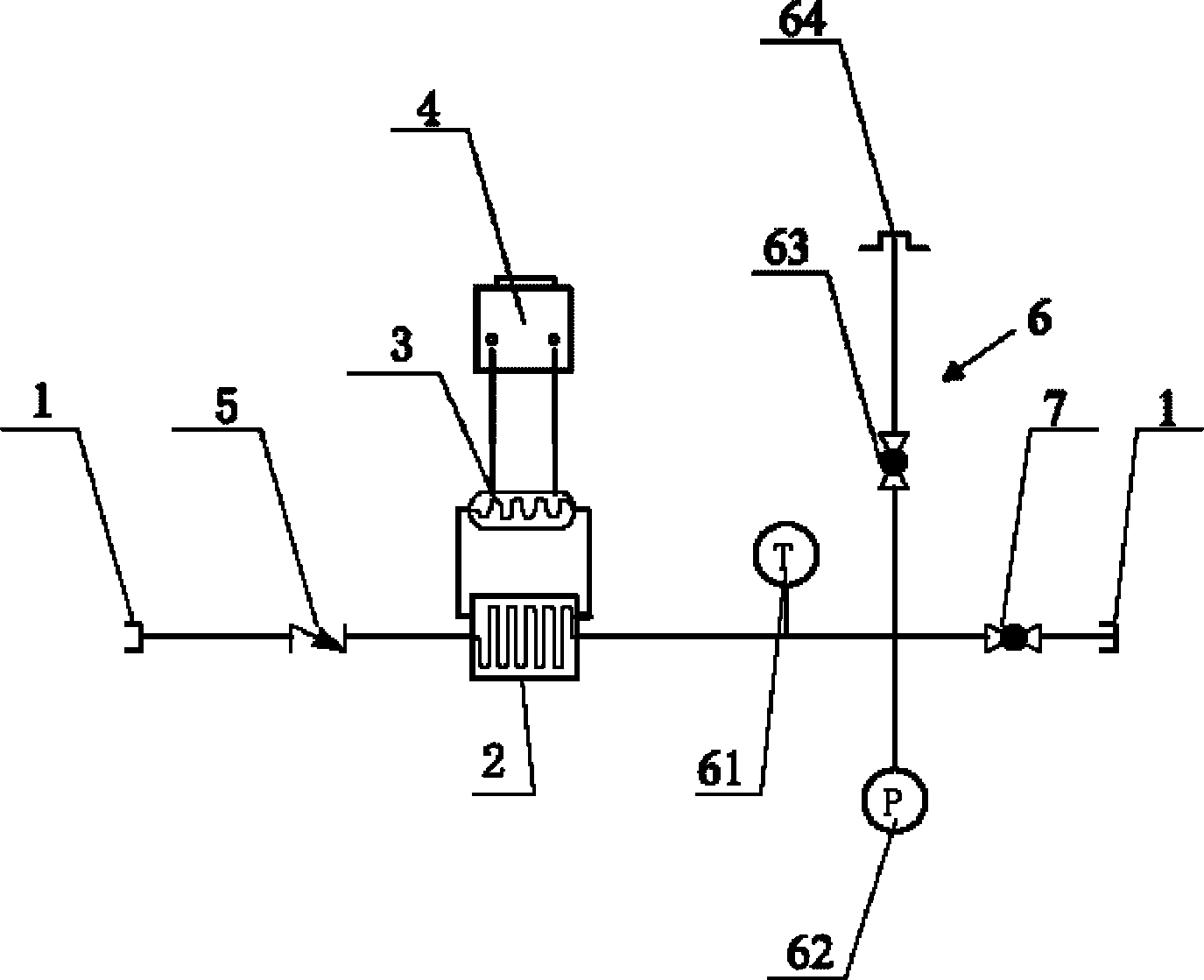

[0030] Such as figure 1 A refrigeration cycle system for a 70MPa hydrogen refueling station is shown, which includes: two quick-change joints 1, one of which is connected to a high-pressure hydrogen source and its booster pump, and the other is connected to a 70MPa hydrogen refueling machine; The first heat exchanger 2, in which the high-pressure hydrogen and the cooling liquid perform the first heat exchange; a second heat exchanger 3, in which a condensing agent is arranged, and the cooling liquid and the condensing agent after the first heat exchange are in the The second heat exchange is performed in the second heat exchanger 3; a refrigeration unit 4 is connected with the second heat exchanger 3, and the refrigeration unit 4 refrigerates the condensate in the second heat exchanger 3 through a compressor.

[0031] Further, the system also includes a safety relief device 6, which is arranged at the gas downstream outlet of the first heat exchanger 2, and is used for safely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com