Full-backwater multichannel circulating energy saver for fuel gas hot-water boiler

A gas-fired hot water and economizer technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems that the return water of the hot water boiler system cannot return to the economizer, the water flow rate is high, and the boiler cannot operate normally. Achieve the effects of avoiding low-temperature corrosion, improving thermal efficiency, and reducing temperature difference stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

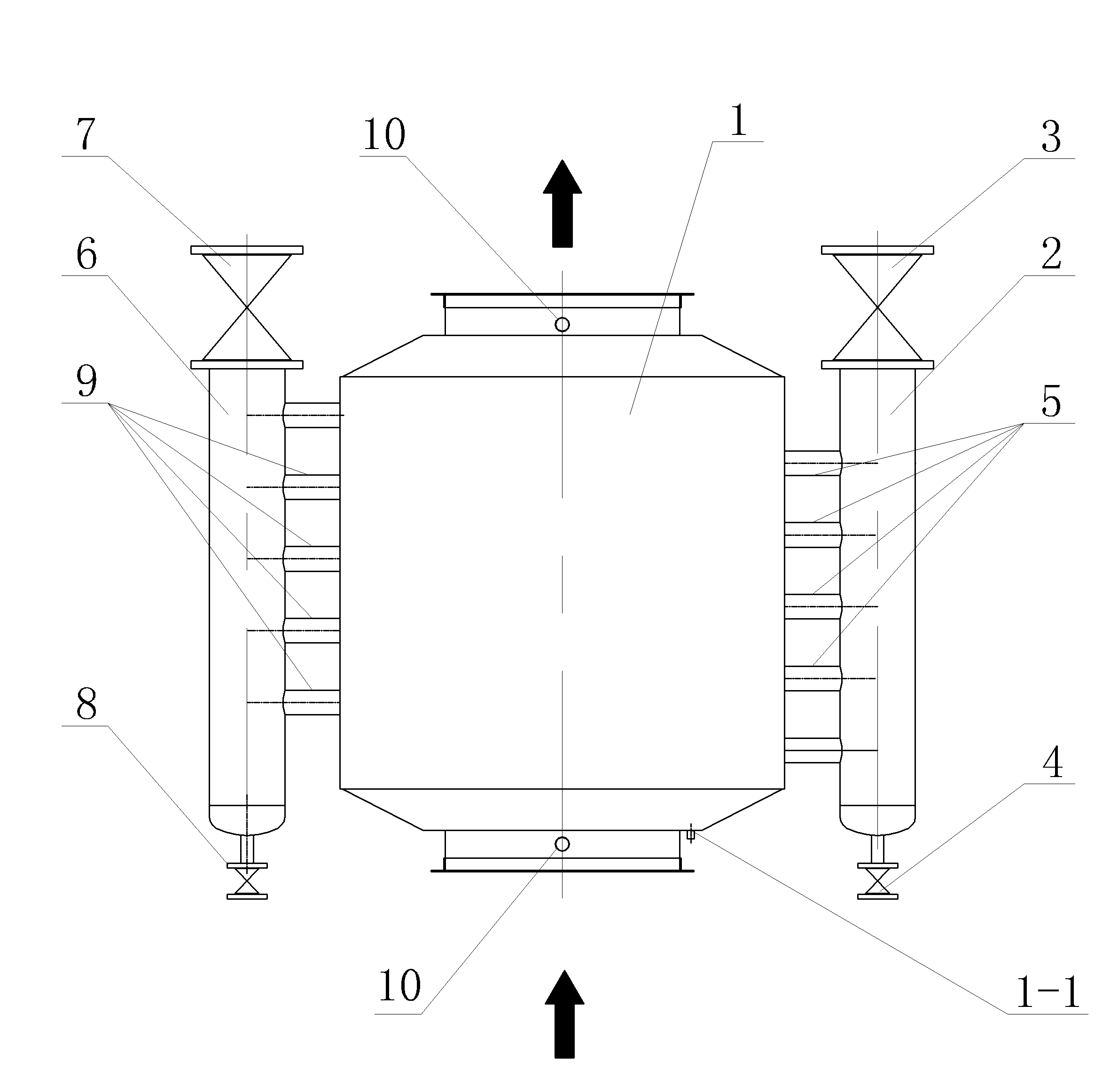

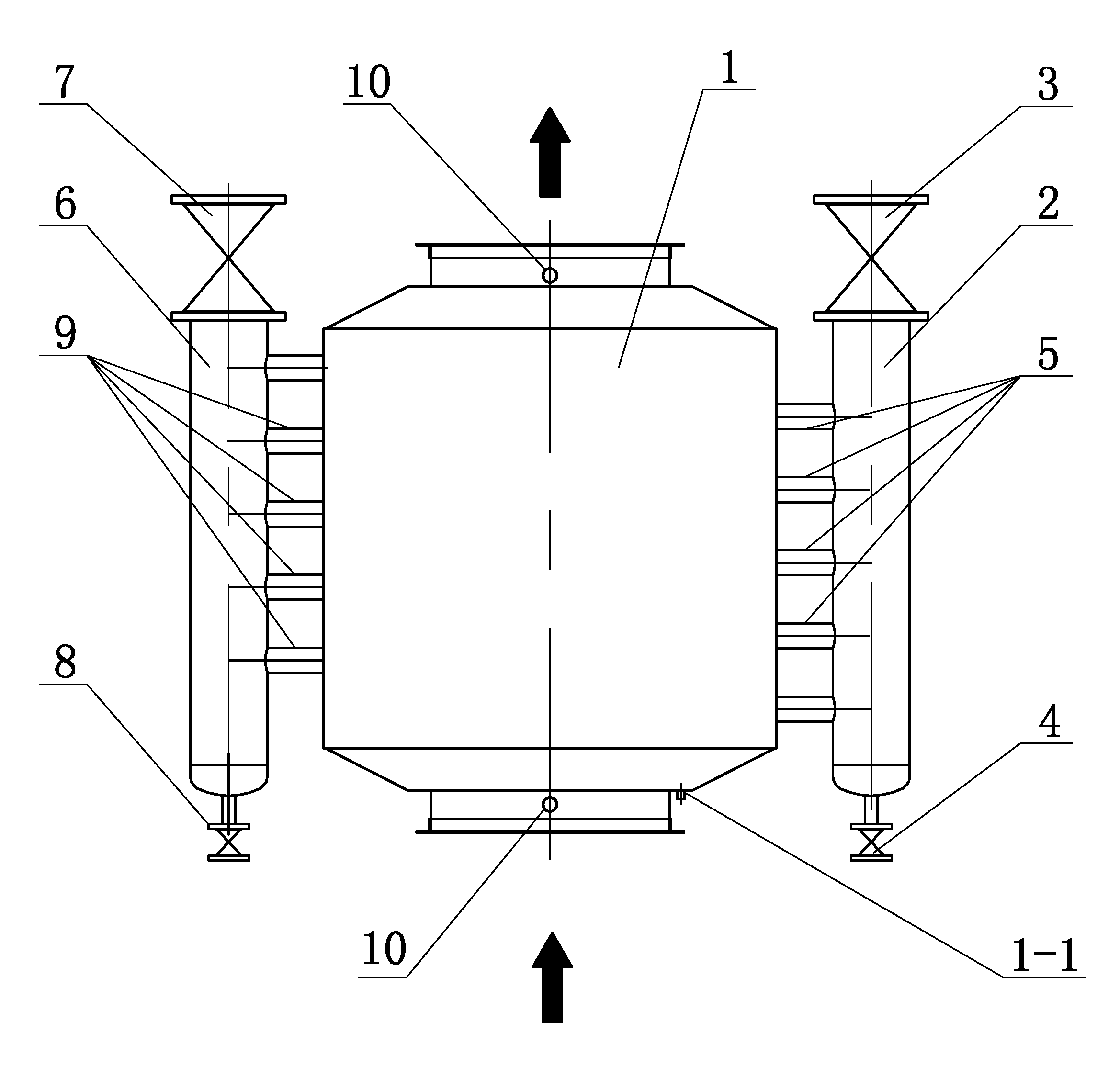

[0010] Specific implementation manner one: such as figure 1 As shown, the fuel-fired gas hot water boiler full-return water multi-cycle economizer of this embodiment includes an economizer body 1, and a flue gas condensate drain 1-1 is processed at the lower end of the economizer body 1. The circuit circulation economizer also includes a circulating water outlet header 2, a first water control valve 3, a first drain valve 4, a circulating water inlet header 6, a second water control valve 7, a second drain valve 8, and a plurality of first A pipeline 5 and a plurality of second pipelines 9, the circulating water outlet header 2 is in communication with the economizer body 1 through a plurality of first pipelines 5, and the circulating water inlet header 6 passes through a plurality of second pipelines 9 is connected to the energy-saver body 1, the upper end of the circulating water outlet header 2 is equipped with a first water control valve 3, the lower end of the circulating ...

specific Embodiment approach 2

[0011] Specific implementation manner two: such as figure 1 As shown, the number of the first pipeline 5 in this embodiment is 2-10. With this design, multi-channel circulation is adopted to reduce the water flow rate in the tube, so that all circulating water in the boiler returns to the main body of the economizer. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation manner three: such as figure 1 As shown, the number of second pipelines 9 in this embodiment is 2-10. With this design, multi-channel circulation is adopted to reduce the water flow rate in the tube, so that all circulating water in the boiler returns to the main body of the economizer. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com