Dry-heat rock heat exchange device capable of achieving local secondary heat exchange

A heat exchange device and secondary heat exchange technology, applied in the direction of indirect heat exchangers, heat exchanger types, geothermal energy, etc., can solve the problems of low water temperature at the water outlet and low heat exchange efficiency, so as to improve heat exchange efficiency, Small footprint and low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment the present invention is described in further detail:

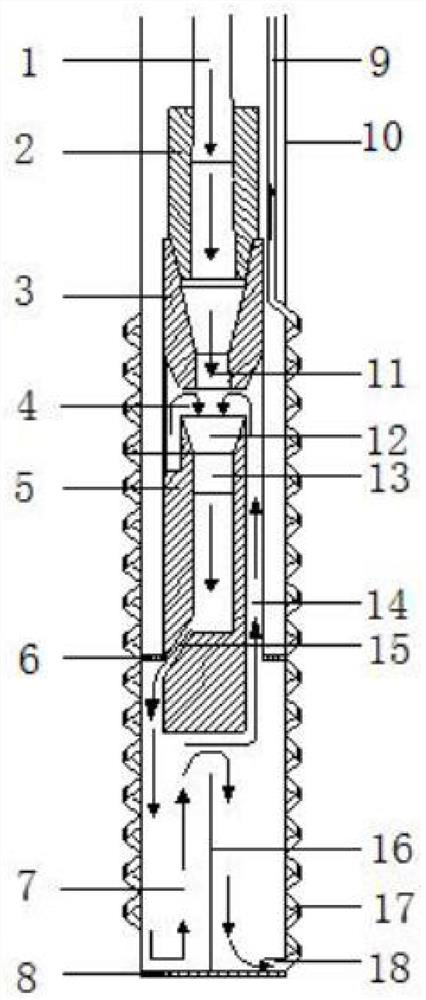

[0027] see figure 1 , the direction of the arrow in the figure is the direction of water flow. The structure of a specific embodiment of the present invention includes a water supply pipe 1, a different-diameter joint 2, a nozzle joint 3, a spray chamber 4, a diffuser 5, an upper head 6, a water collector 7, a bottom head 8, a return pipe 9, and heat insulation Pipe 10, nozzle 11, mixing chamber 12, throat pipe 13, return water channel 14, water outlet channel 15, intermediate partition 16, return water channel 17 and return water port 18. The water supply pipe 1, the nozzle 11, the spray chamber 4, and the diffuser 5 are sequentially arranged in the heat insulation pipe 10 from top to bottom. The water collector 7 communicates with the heat insulation pipe 10 and is arranged at the bottom of the heat insulation pipe 10. The water supply pipe 1 passes through The diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com