Load simulator based on follow-up moment load

A technology of load simulator and dynamic torque, which is applied in the direction of instruments, machine/structural component testing, measuring devices, etc., to achieve the effects of reducing interference torque interference, stable force/torque, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

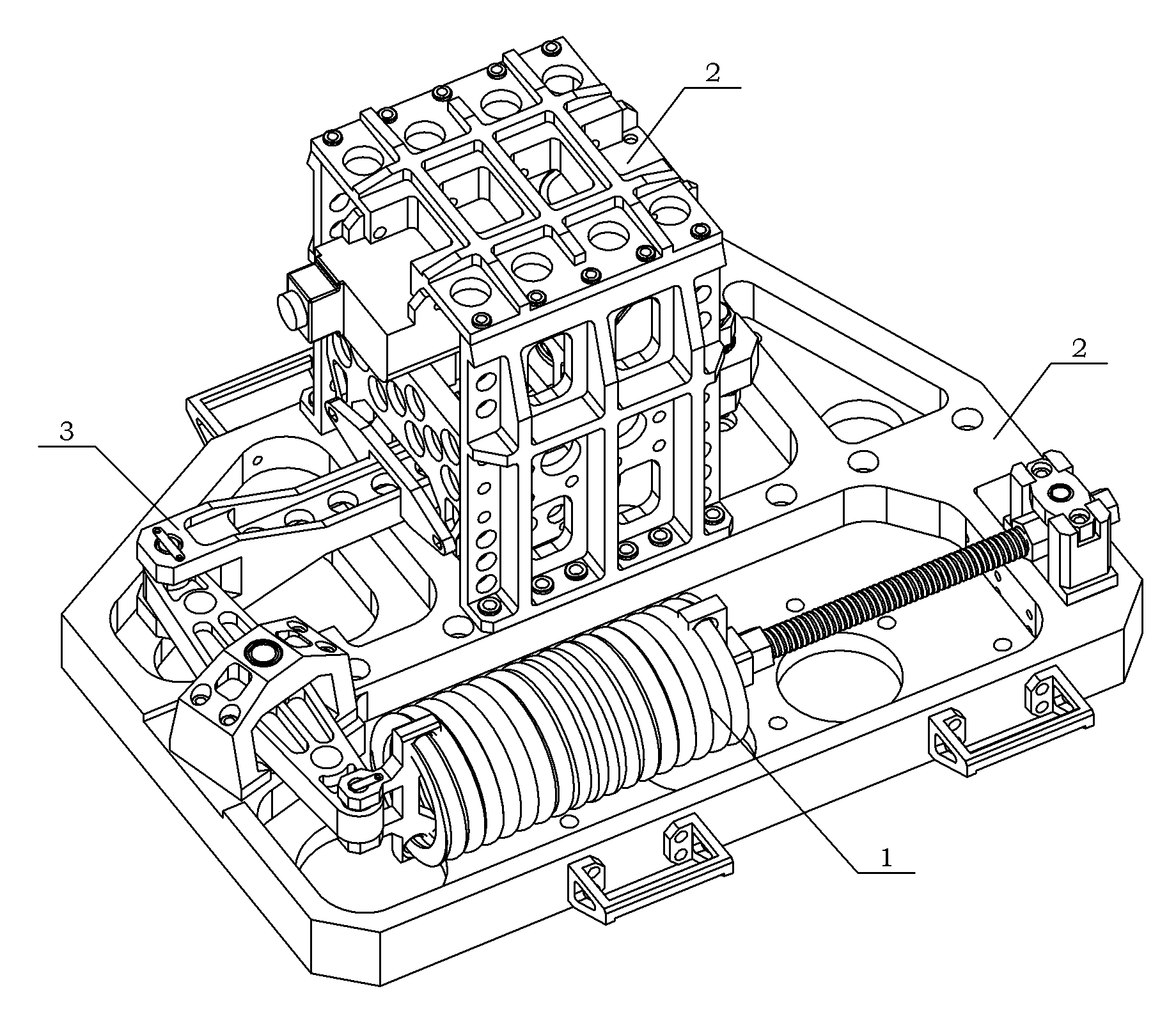

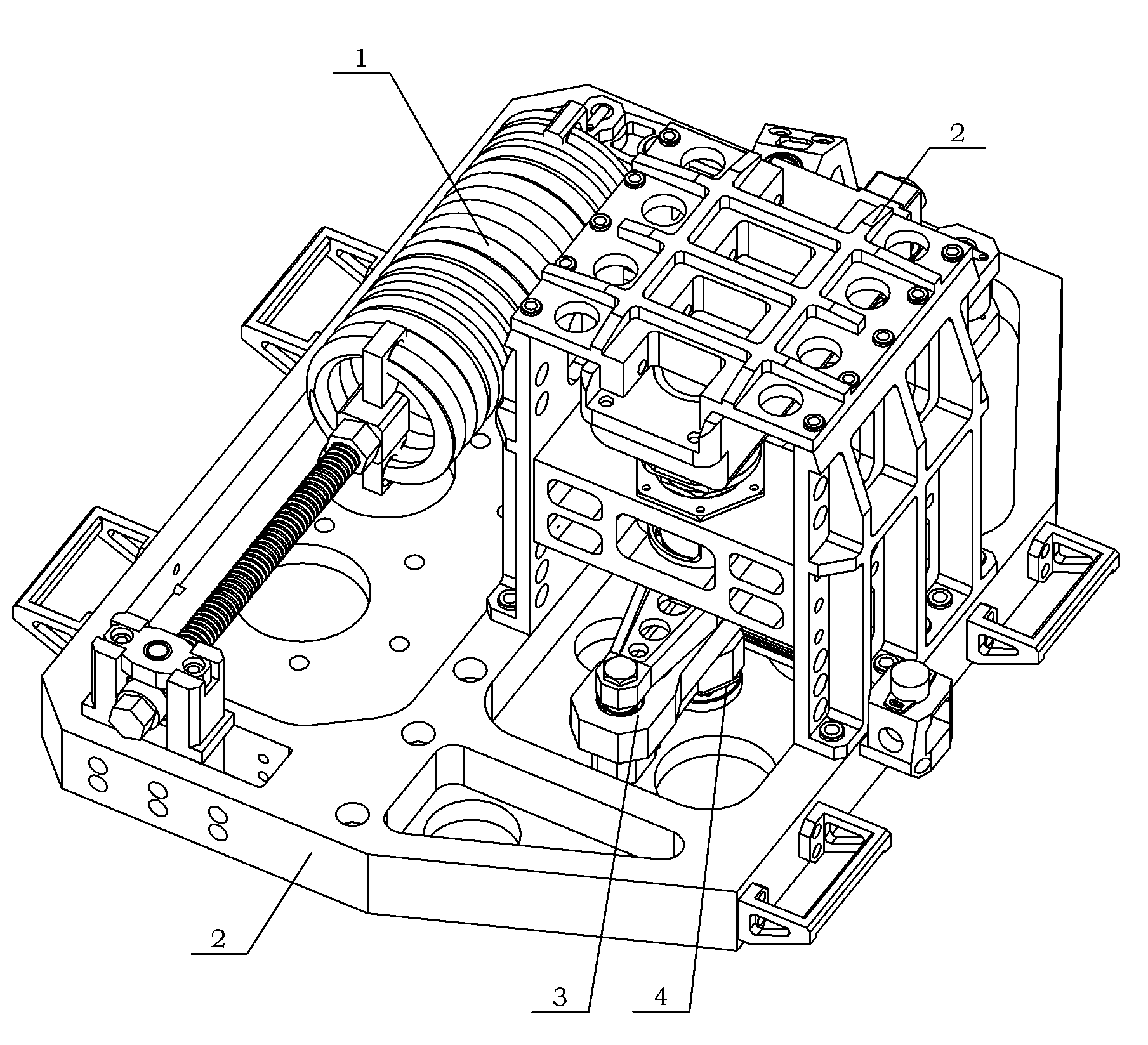

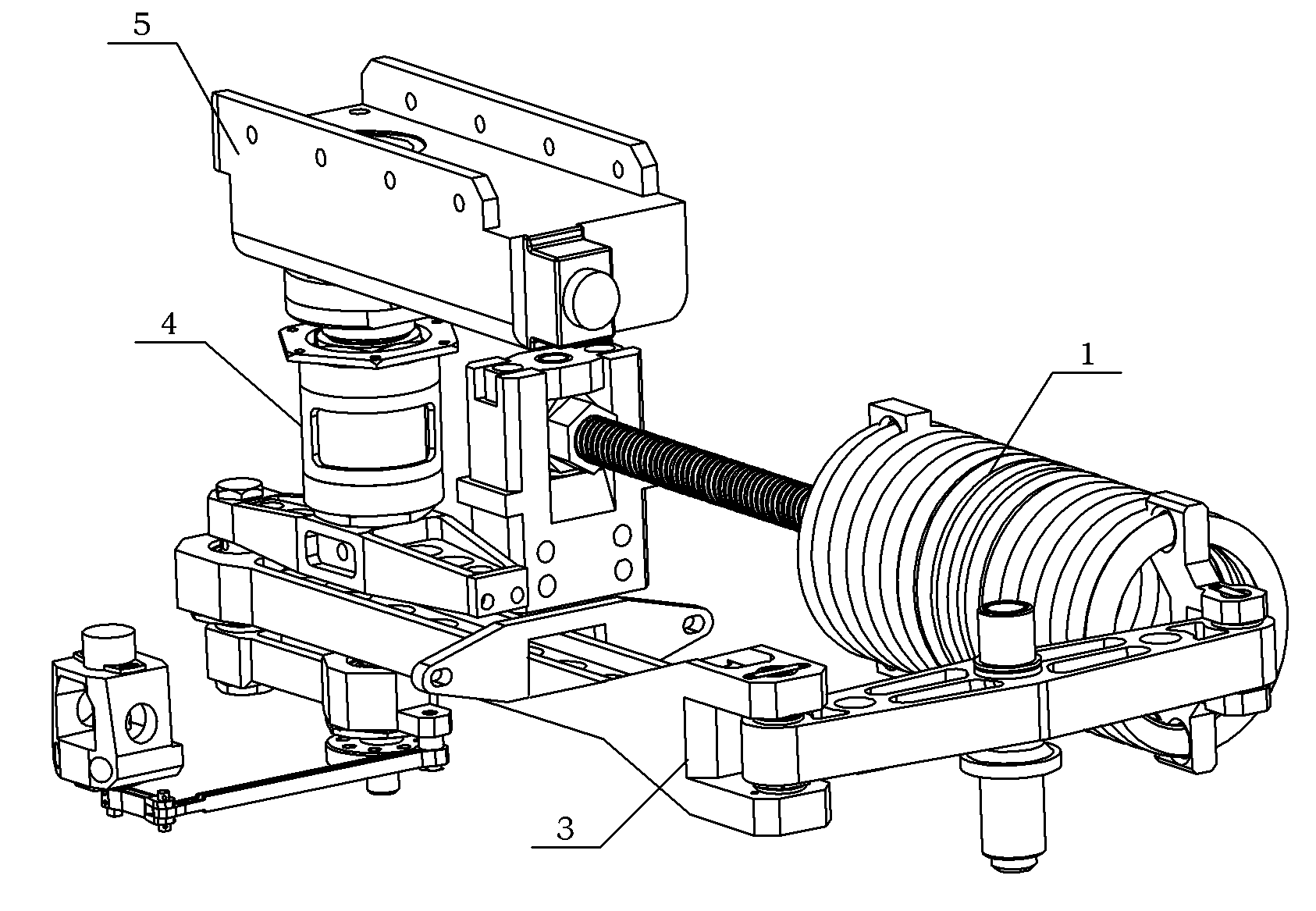

[0034] see figure 1 , Figure 1A , Figure 1B Shown, a kind of load simulator based on follower moment load of the present invention, it comprises elastic force application assembly 1, skeleton assembly 2, connecting rod assembly 3 and torque measurement assembly 4; Elastic force application assembly 1, connecting rod assembly 3 and the torque measurement assembly 4 are installed on the skeleton assembly 2.

[0035] The elastic force applying component 1 is used to load the test piece 5 with different gradients of pre-applied force.

[0036] Skeleton assembly 2 is used on the one hand to realize the support and fixed installation of the elastic force application assembly 1, connecting rod assembly 3 and torque measurement assembly 4 in the load simulator based on the follower moment load designed by the present invention; The load simulator of the follow-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com