Patents

Literature

53results about How to "Small disturbance torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

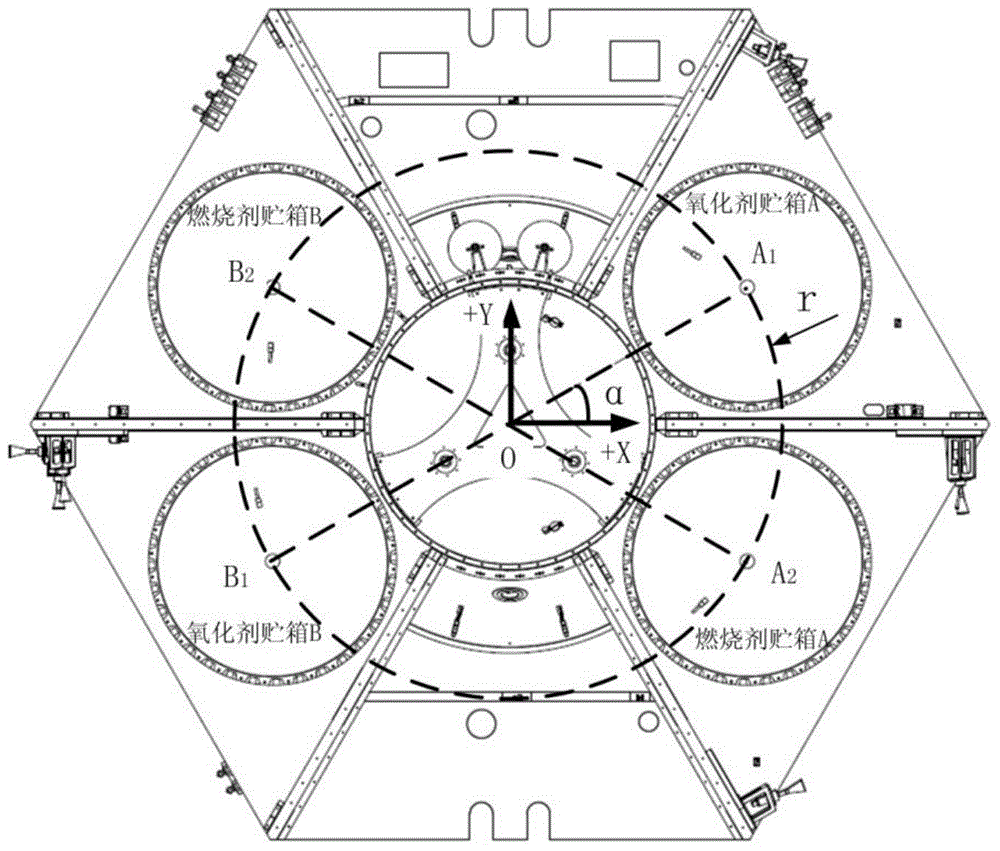

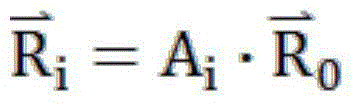

Zero-counterweight barycenter deploying method for parallel tiling tank satellite

ActiveCN104401506AAchieve regulationReduce the amount of change in the center of massSpacecraft guiding apparatusSatelliteBarycentric coordinates

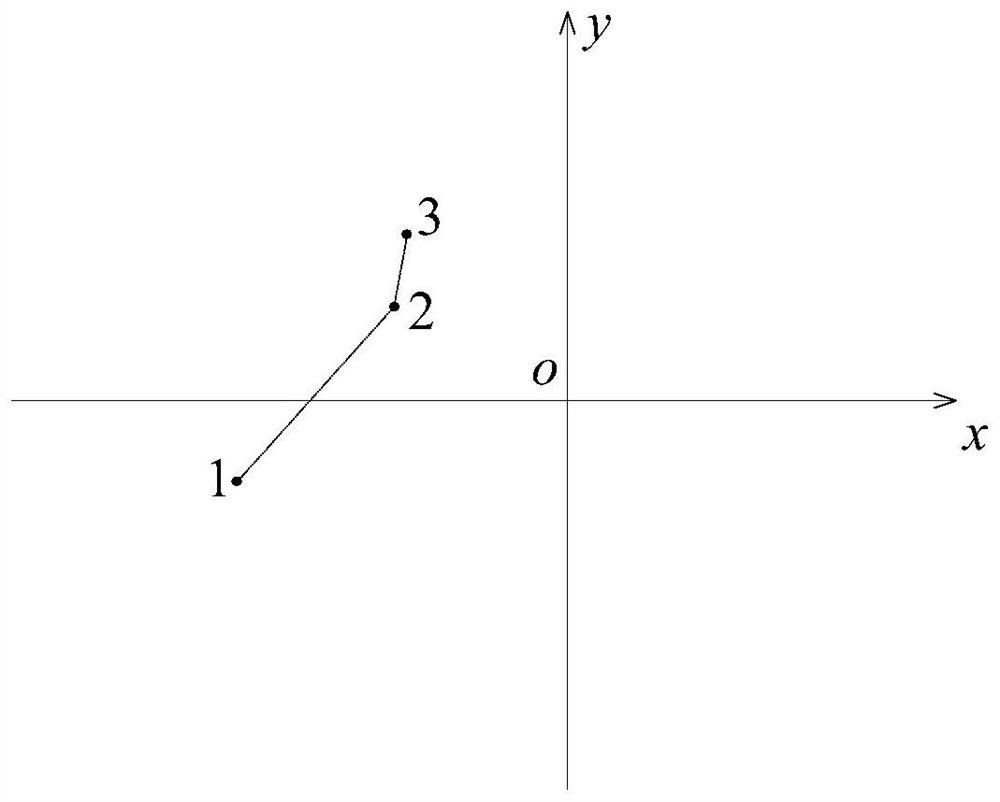

The invention provides a zero-counterweight barycenter deploying method for a parallel tiling tank satellite. The method comprises the following steps: (1) preliminarily calculating a satellite barycenter position; (2) preliminarily calculating an adjustable scope of a barycenter; (3) after testing mass characteristics of the satellite, acquiring a measured value of the barycenter, analyzing and calculating the mass and position of a to-be-adjusted propellant according to the measured value, and causing the barycenter to approach to the original point; (4) performing propellant filling for the satellite according to a calculating result of the filling quantity of the propellant of each tank, controlling different filling quantities, and meanwhile, setting a work state after filling. The invention provides the new barycenter deploying method for a parallel tiling tank layout high-orbital satellite; under the condition of not increasing the total mass of the satellite, the original barycenter offset of the satellite is reduced, so that the barycenter variation of a satellite orbital transfer section is reduced, the disturbance torque is reduced, the safety of the satellite orbital transfer is ensured, the consumption of the propellant is reduced, and the service life of the satellite is prolonged.

Owner:SHANGHAI SATELLITE ENG INST

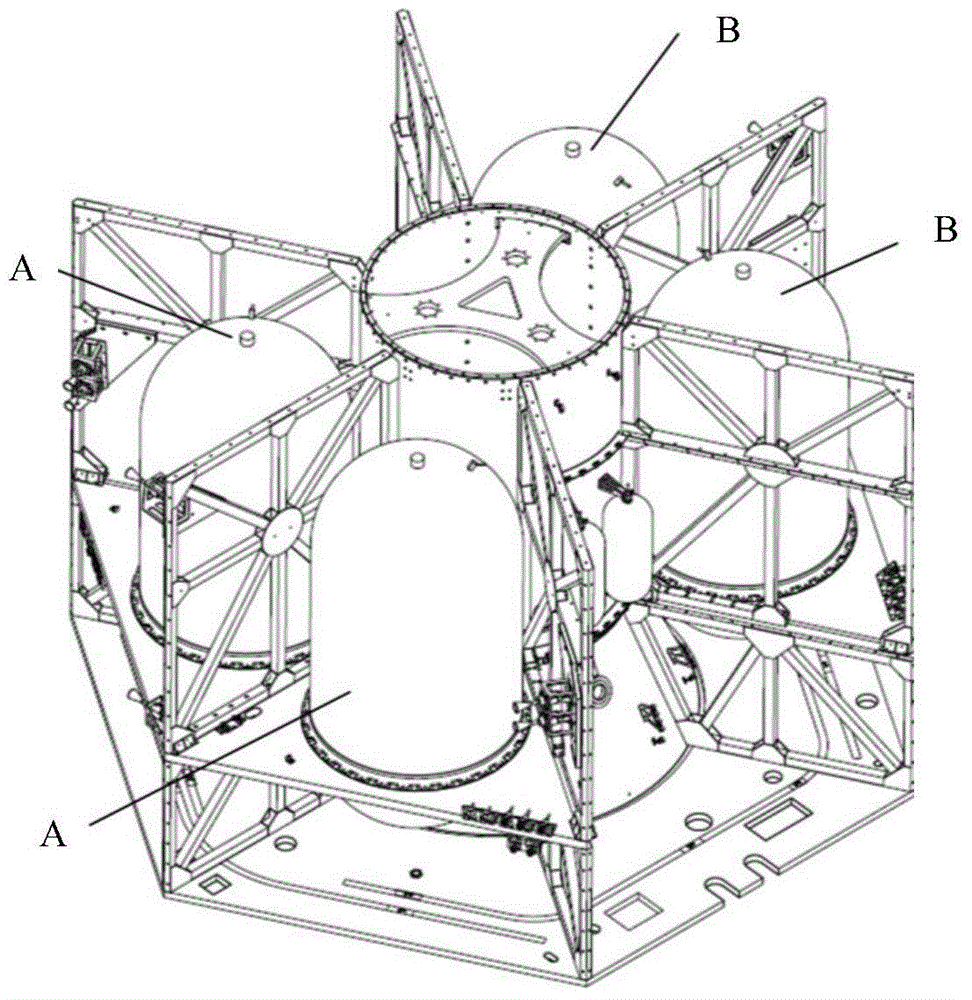

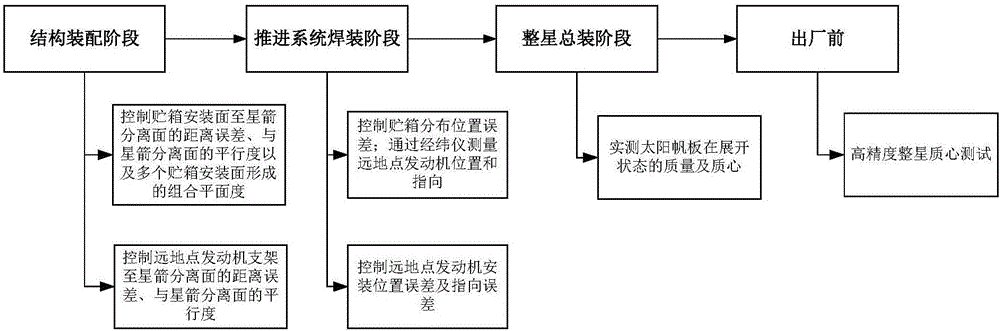

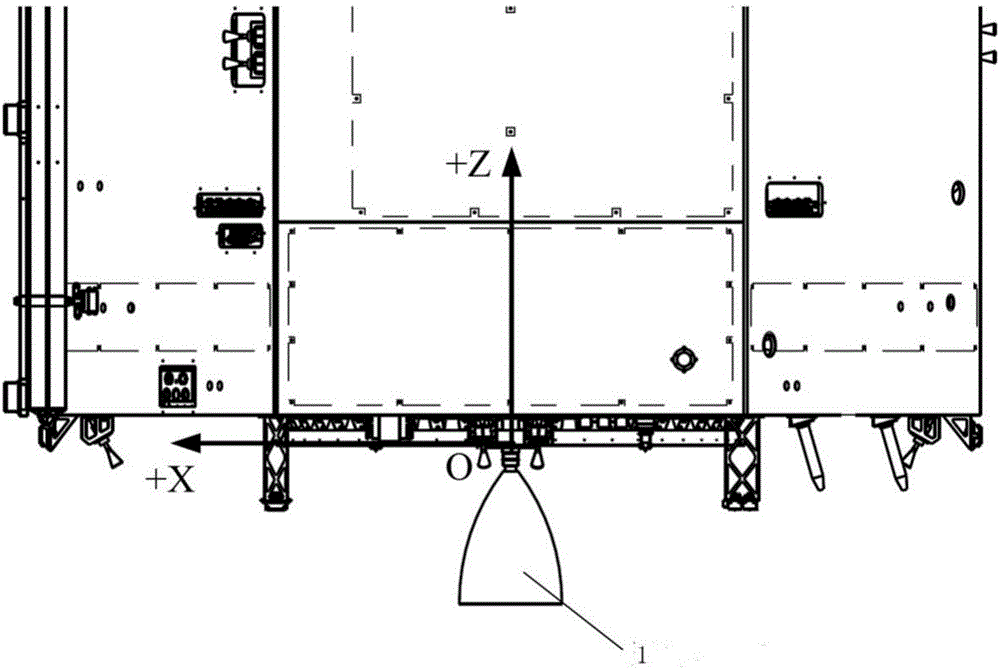

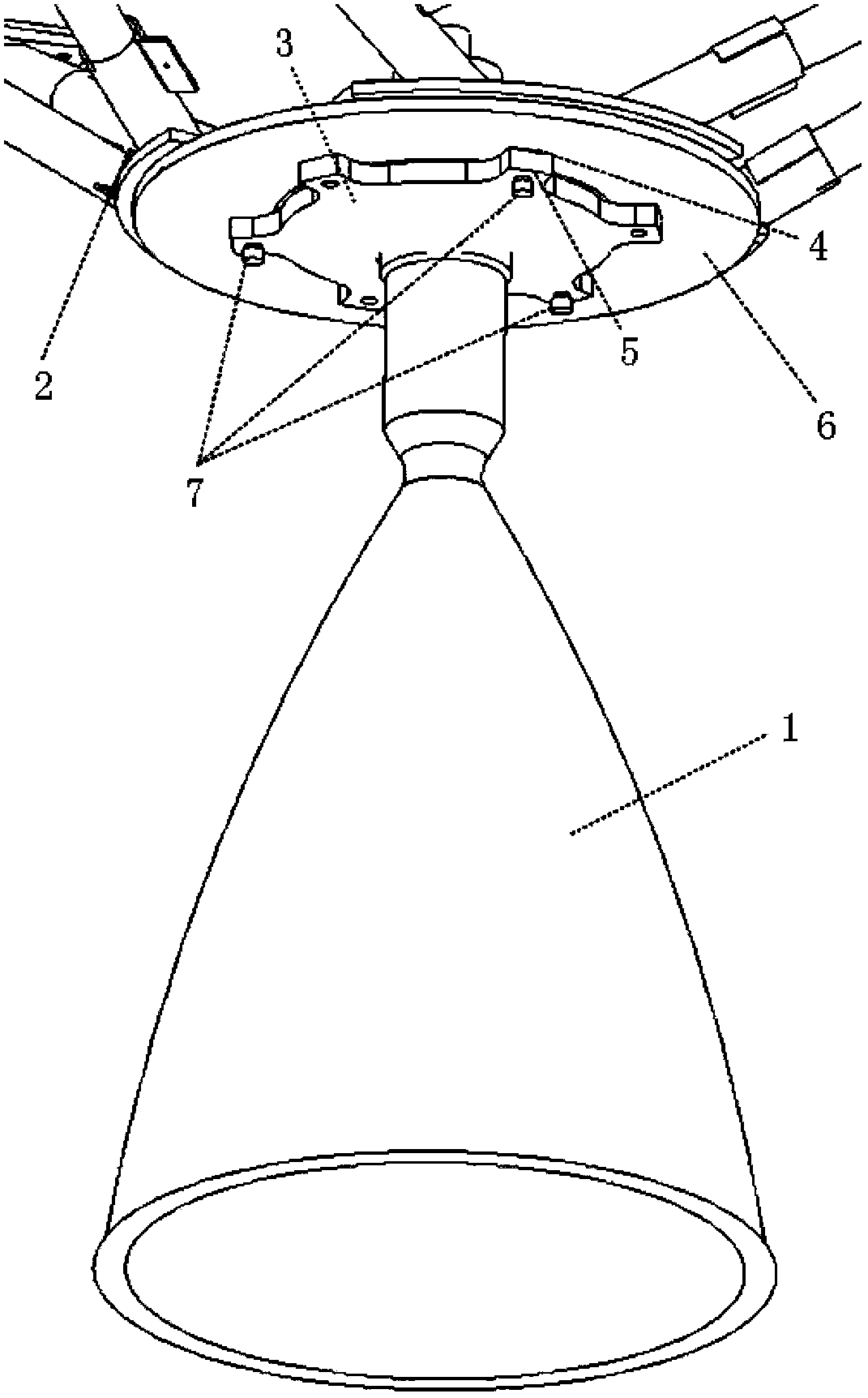

Transverse centroid high-precision guarantee method for parallel tiled tank satellite in AIT stages

ActiveCN106542114AImprove the determination accuracyReduce lateral centroid variationArtificial satellitesAircraft assemblyGeneral assemblySatellite orbit

The invention provides a transverse centroid high-precision guarantee method for a parallel tiled tank satellite in AIT stages. The transverse centroid high-precision guarantee method comprises the following steps: in the structural assembly stage, tank mounting plate form and position errors as well as apogee engine bracket mounting errors are controlled; in the propulsion system welding assembly stage, tank mounting position errors as well as apogee engine mounting position and pointing errors are controlled; in the whole satellite general assembly stage, the quality and the centroid are controlled when a solar array in the unfolded state; and before delivery, the whole satellite transverse centroid measurement is performed through high-precision centroid measurement equipment. According to the transverse centroid high-precision guarantee method provided by the invention, a plurality of transverse centroid guarantee measures are implemented in all the AIT stages of the whole satellite, the transverse centroid of the satellite is controlled to be near the origin when the solar array is in the initial unfolded state, the transverse centroid determination accuracy of the satellite is improved (lower than or equal to 1 mm), and the transverse centroid change of a satellite orbit maneuver section is reduced, thereby reducing the disturbance torque generated by an apogee engine and ensuring safe orbit maneuver; and meanwhile, the consumption of a propellant is lowered.

Owner:SHANGHAI SATELLITE ENG INST

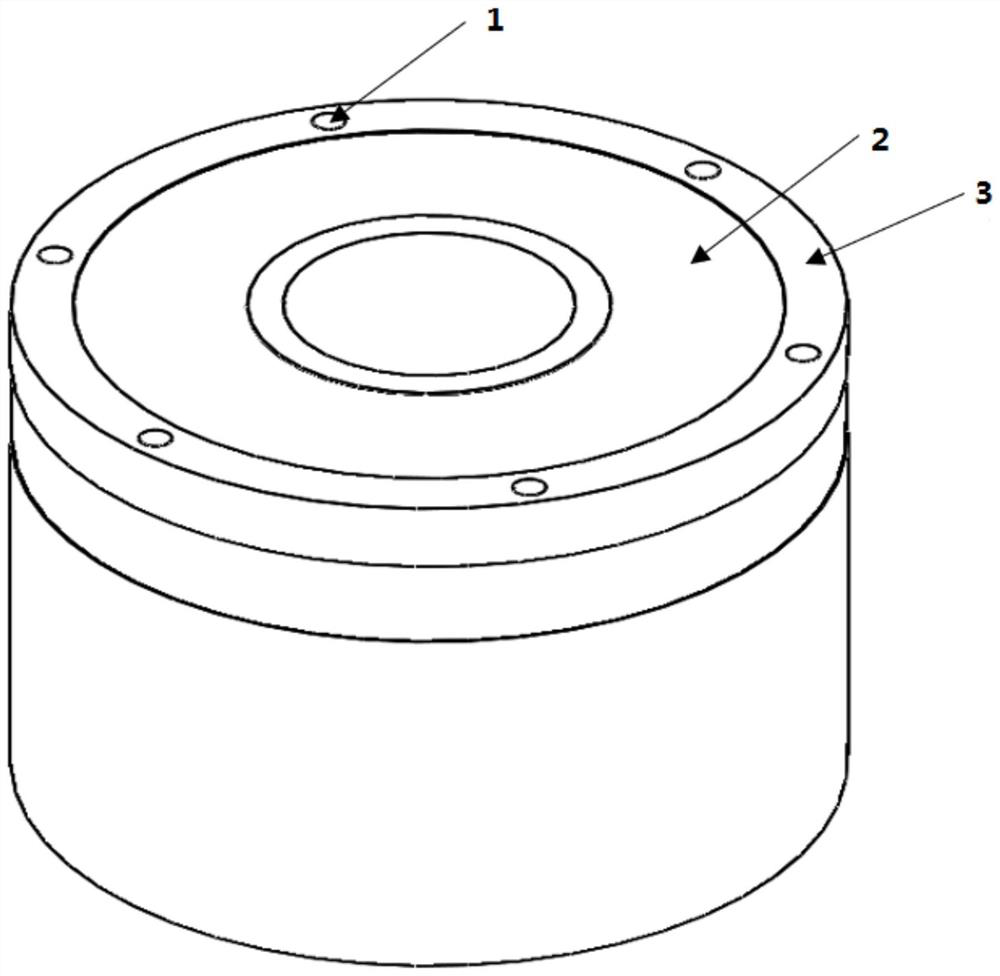

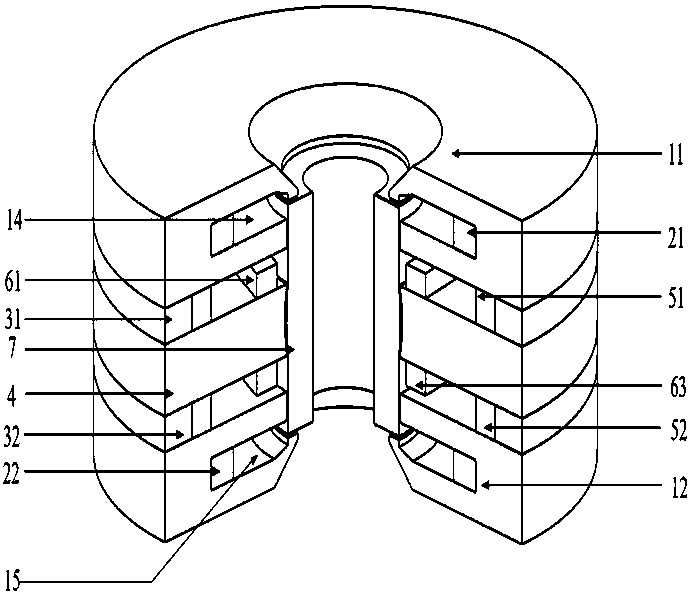

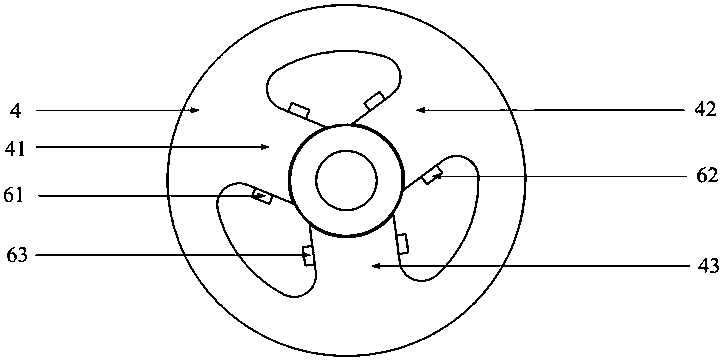

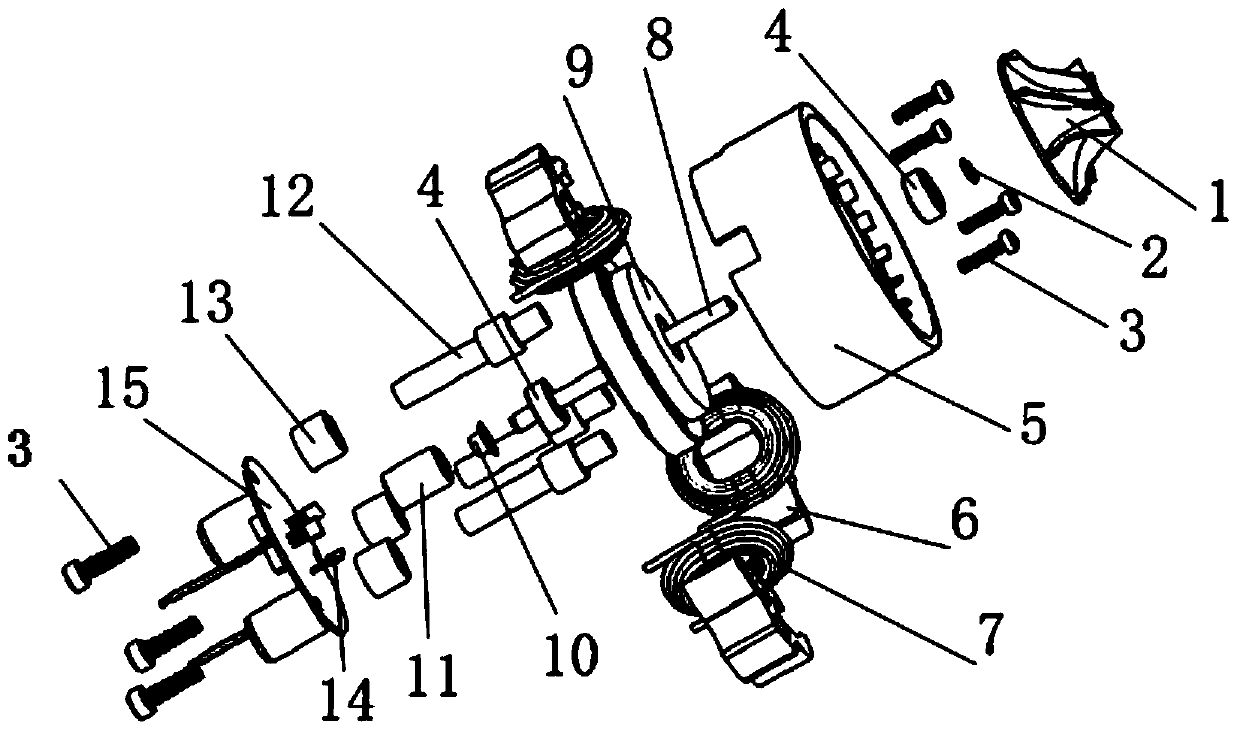

Magnetic suspension gyroscopes

ActiveCN101256077ASimple structureImprove reliabilityRotary gyroscopesMagnetic holding devicesGyroscopeMagnetic valve

The invention relates to a magnetically suspended gyroscope, which solves the technical problem that the existing gyroscope has bad precision and high hazard rate. The invention includes a shell, a gyro machine which is equipped in the shell, a sensor, a torquer, a floating ball and a magnetic suspension device, the magnetic suspension device includes a magnetic suspension magnetic valve, a press ring magnetic valve, a pressure spring, a press ring, a contact terminal, a platen and a limit ring; the magnetic suspension magnetic valve is equipped over the floating ball and fixed on the shell, the press ring magnetic valve is equipped around the magnetic suspension magnetic valve in a circle and fixed on the shell, many pressure springs are uniformly between the press ring and the press ring magnetic valve in circumference, the platen is fixed on the extension axis and is perpendicular to the axis, three equally spaced contact terminals are equipped on the outer circumference of the upper surface of the platen, the limit ring is equipped on the inner side of the shell to support the platen. The invention has the merits of high floating precision, low perturbed moment, good adaptive capacity to environment and high gyroscope precision.

Owner:中国航天时代电子公司第十六研究所

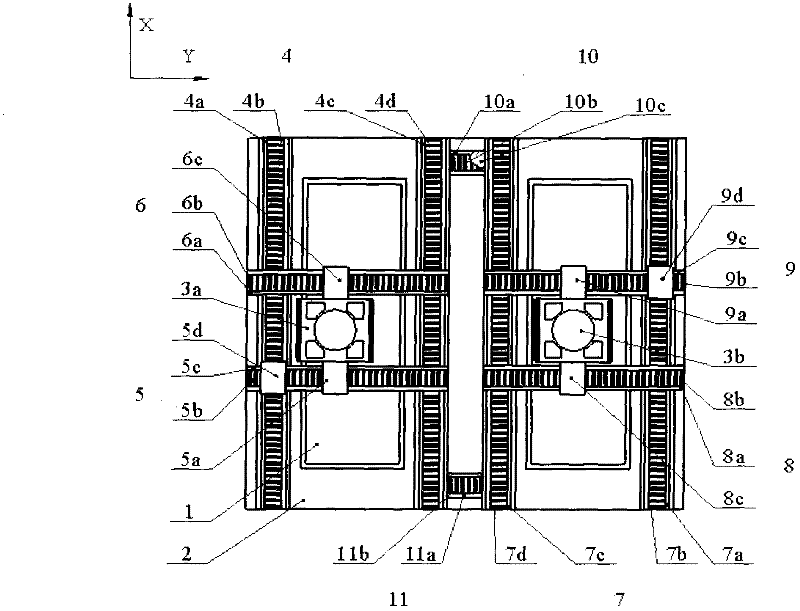

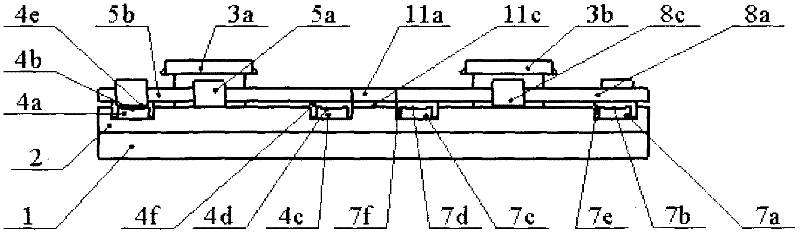

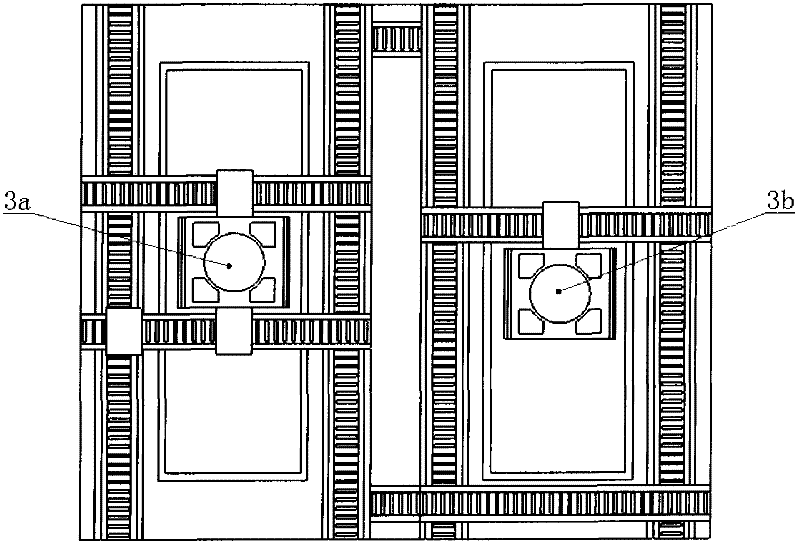

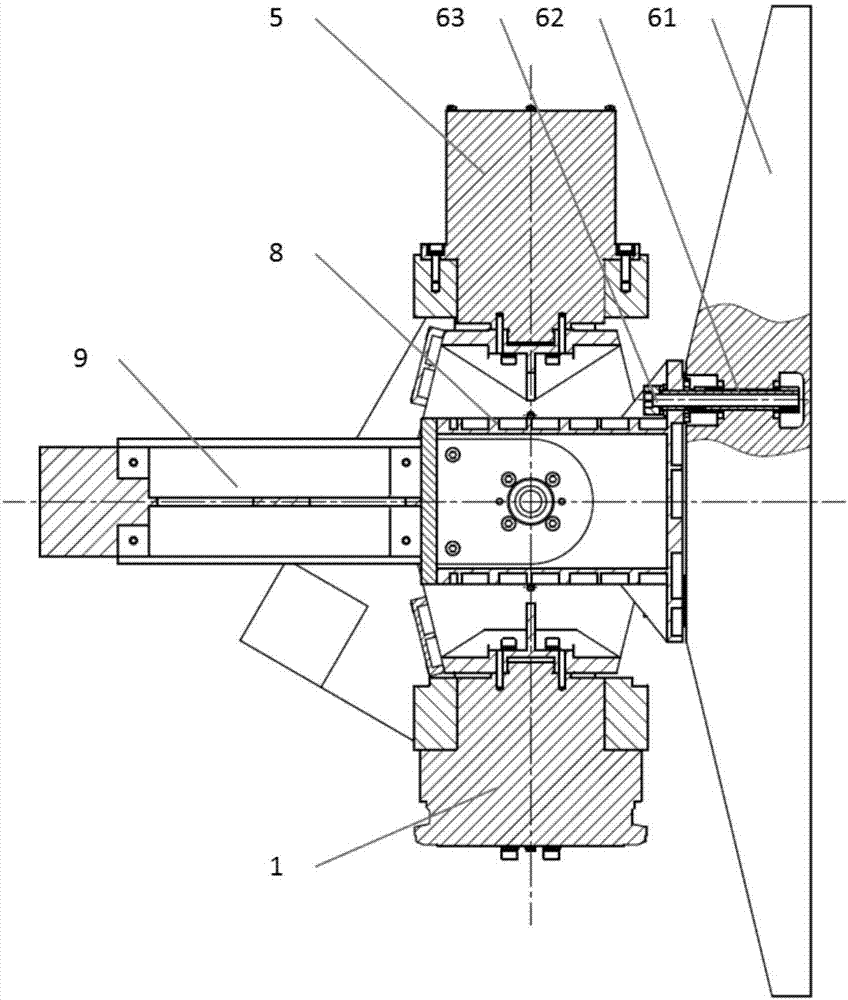

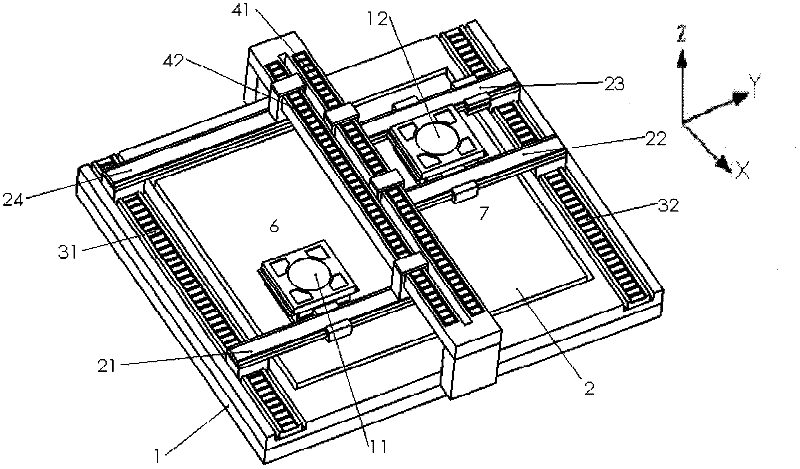

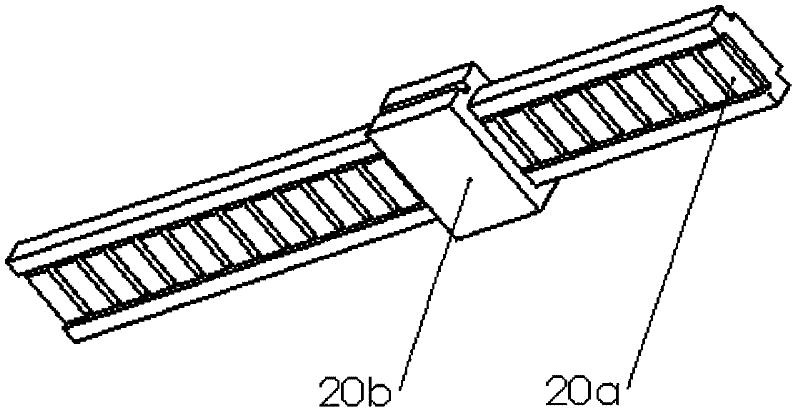

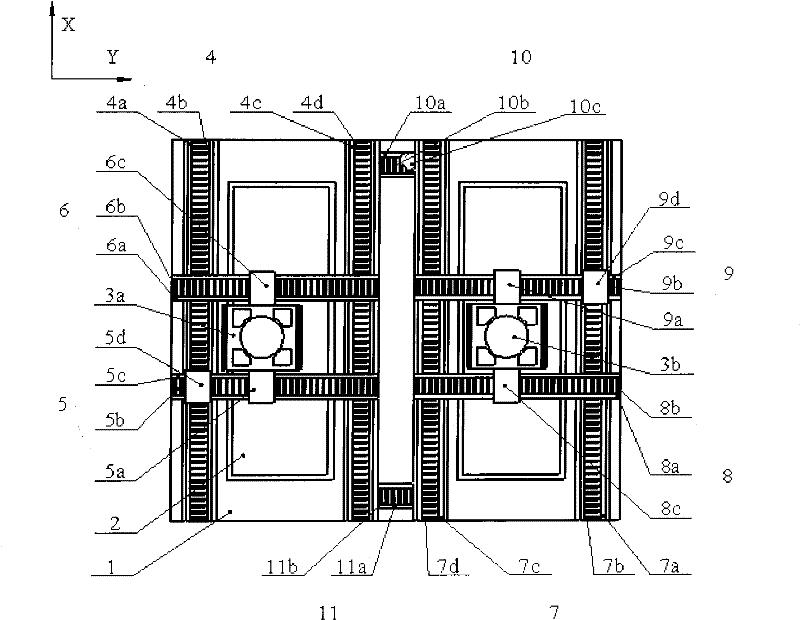

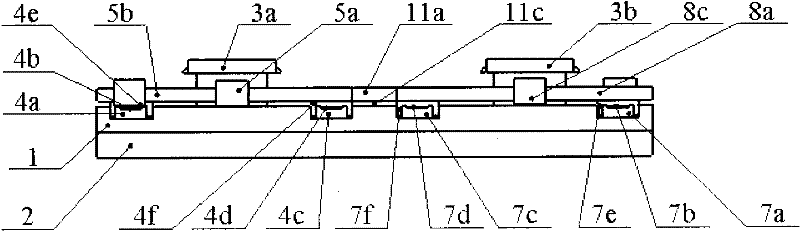

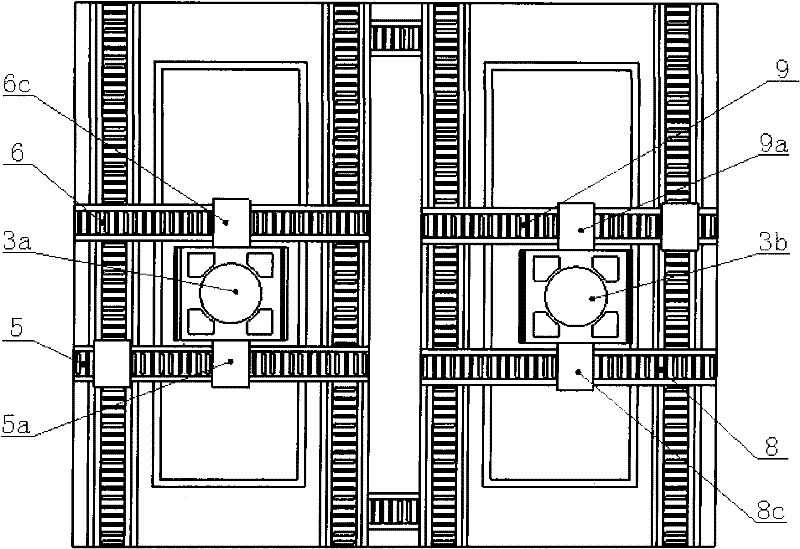

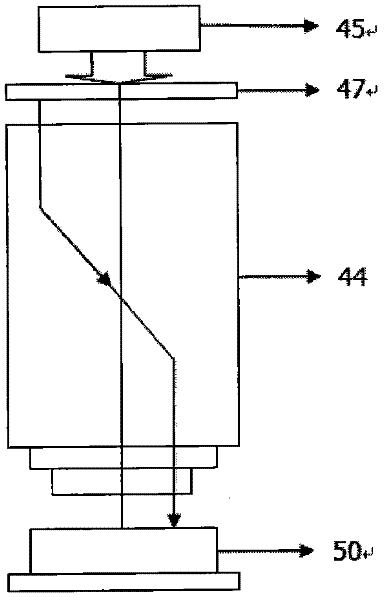

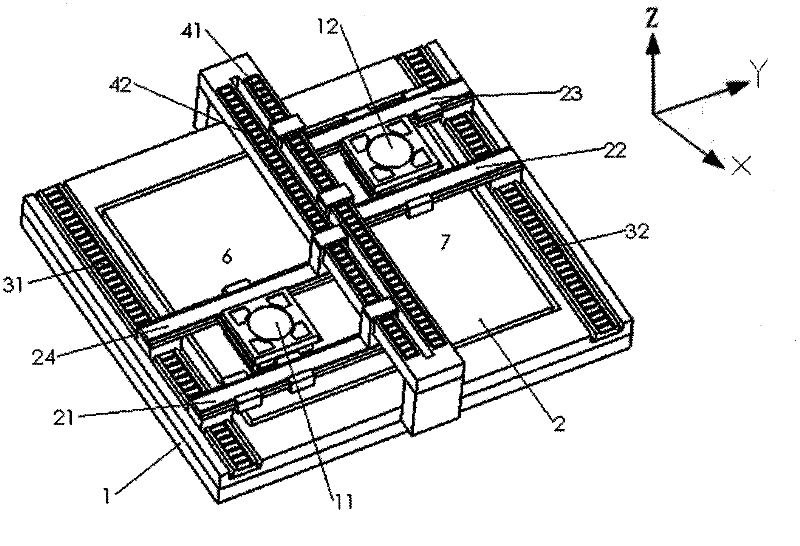

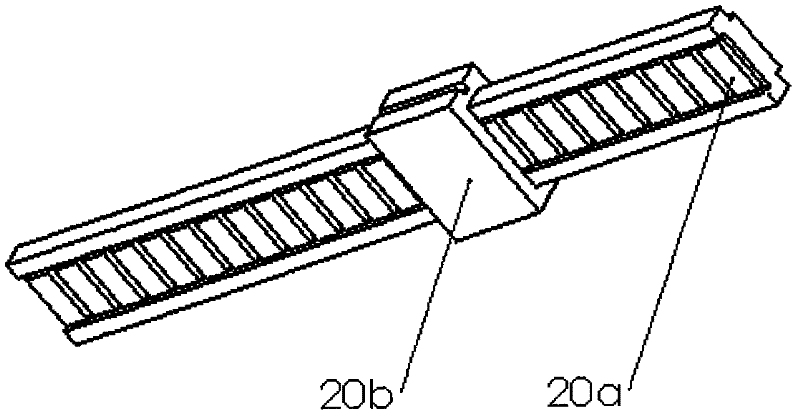

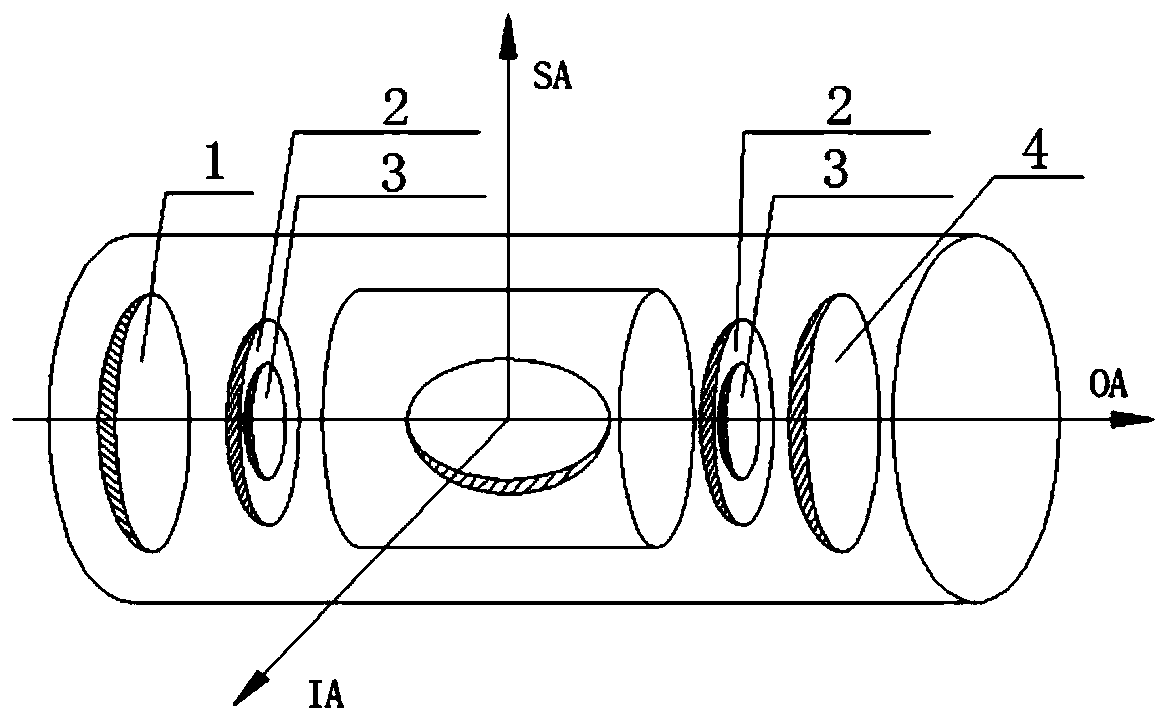

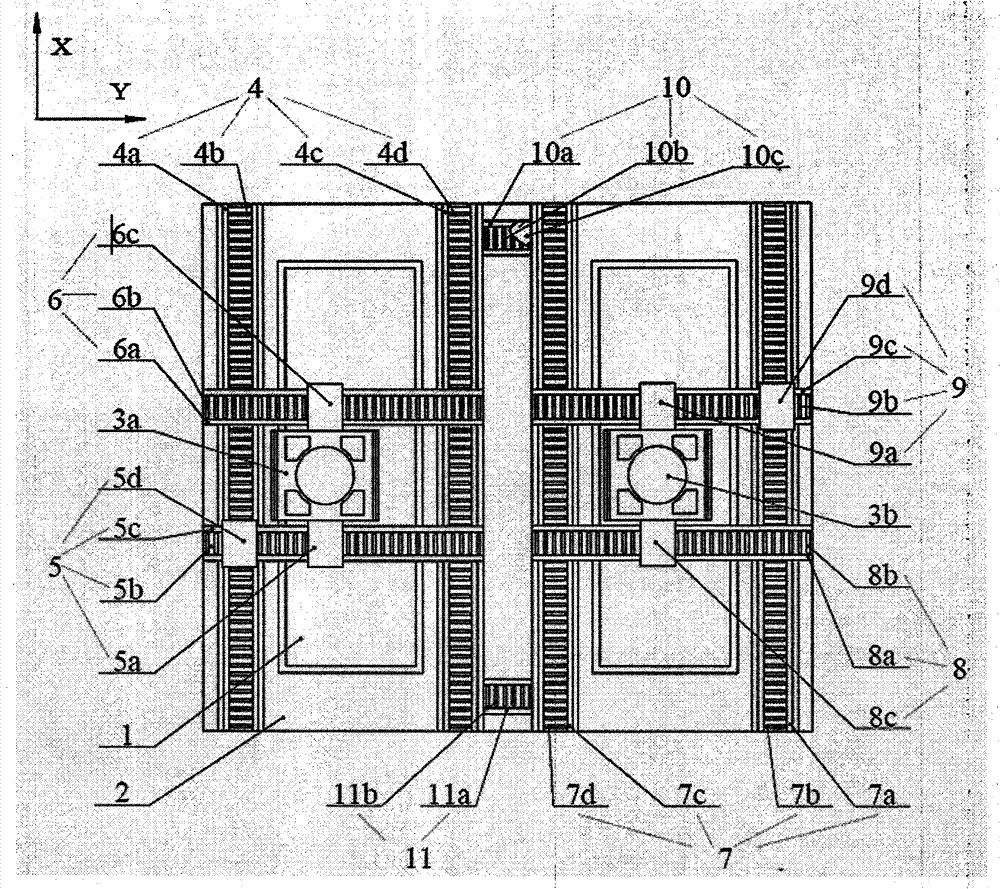

Exchange apparatus and method for double-workpiece stage based on double-guide rail double-drive step scanning

InactiveCN102419517AGreat driving forceSmall qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusButt jointElectric machine

The invention provides an exchange apparatus and method for a double-workpiece stage based on double-guide rail double-drive step scanning, belonging to the technical field of manufacture equipment for semiconductors. The exchange apparatus comprises a base station and workpiece stages located at an prealigning station and an exposure station; four Y-oriented rectilinear motion units and two X-oriented rectilinear motion units are preset on a balancing mass, and three-phase exchanging of the workpiece stages between a prealigning area and an exposure area is finished through butt joint between rectilinear motor stators of the Y-oriented rectilinear motion units and Y-oriented transitional rectilinear motion units; a first Y-oriented rectilinear motor mover 1 is fixedly connected with a first workpiece stage, a fourth Y-oriented rectilinear motor mover 1 is fixedly connected with a second workpiece stage, and the Y-oriented rectilinear motion units and the X-oriented rectilinear motion units form a double-guide rail double-drive structure at the exposure station. According to the invention, during exchanging of the workpiece stages, three phases are employed, which allows exchanging efficiency to be improved; in specific embodiments of the invention, the advantages of small inertia of motion, short time for stabilization, great structural rigidity, centroidal driving at the exposure station and the like are realized.

Owner:HARBIN INST OF TECH

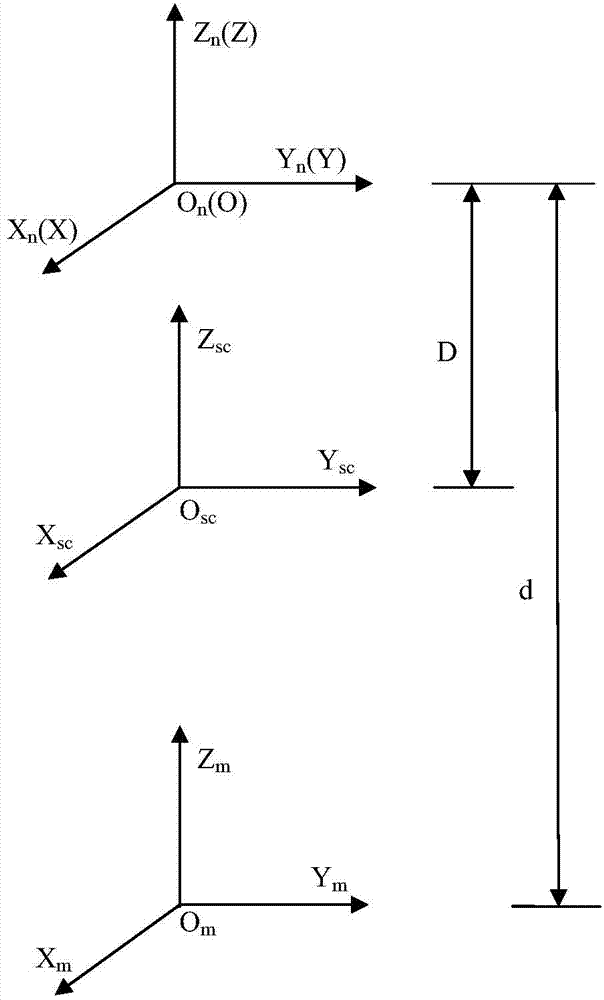

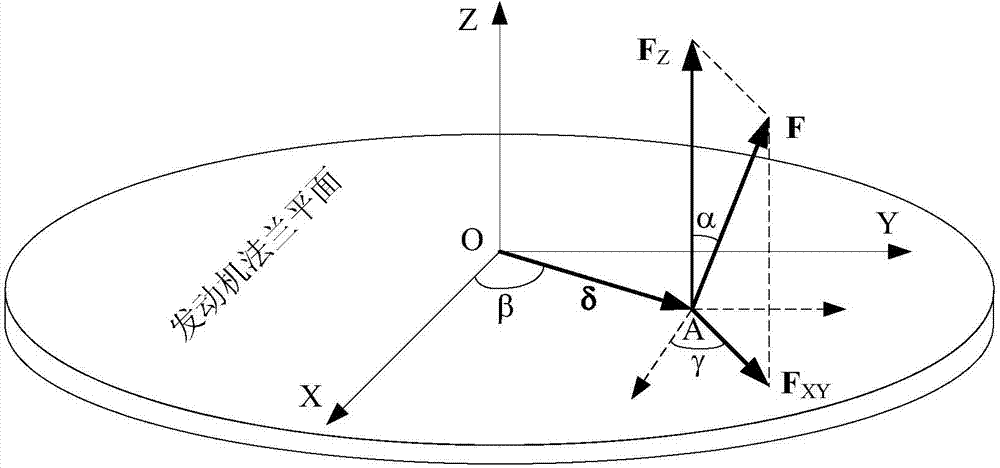

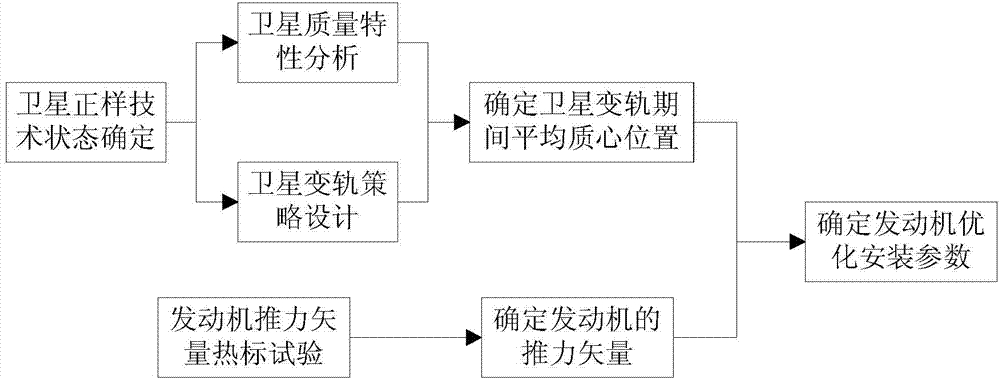

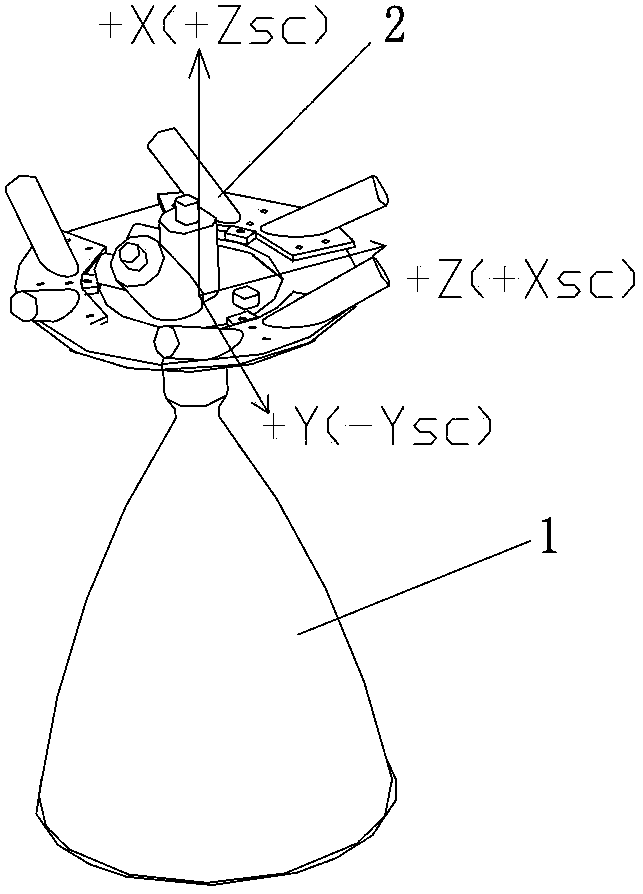

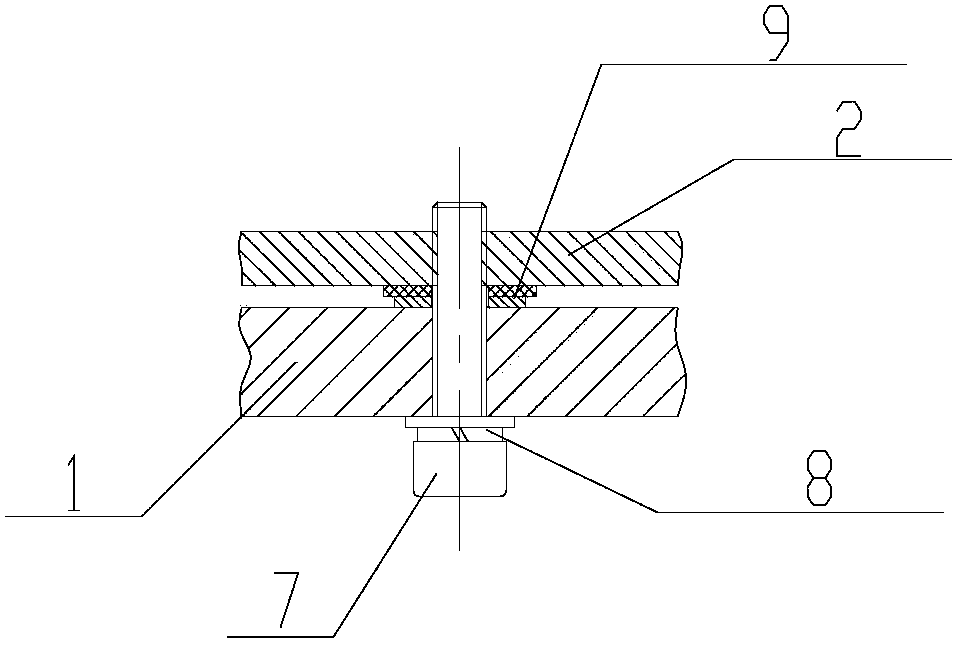

Method for determining mounting parameters of orbit control engines of satellites

ActiveCN103593505ASmall disturbance torqueExtended life on orbitSpecial data processing applicationsEngineeringOrbit

The invention discloses a method for determining mounting parameters of orbit control engines of satellites. The method includes determining a mounting position of each engine by the aid of included angles alpha<E>, beta <E> and gamma <E> among a normal line O<m>X<m> of an accurate measurement mirror of the engine and an axis O<sc>X<sc>, an axis O<sc>Y<sc> and an axis O<sc>Z<sc> of a mechanical coordinate system of the corresponding satellite and coordinates x<E>, y<E> and z<E> of the center O<m> of the accurate measurement mirror of the engine on the axis O<sc>X<sc>, the axis O<sc>Y<sc> and the axis O<sc>Z<sc> of the mechanical coordinate system of the satellite. The method has the advantages that change conditions of mass centers of the satellites and thrust vectoring thermal marking results of the engines are comprehensively considered, so that the mounting parameters of the engines can be optimally determined, disturbance torque generated in orbital transfer periods of the satellites can be reduced, satellite propellants can be saved, and the in-orbit lives of the satellites can be prolonged; thrust of each engine points to the average mass center of the corresponding satellite in the corresponding orbit transfer period, so that counterweights for the satellites can be reduced or can be omitted, and the effective load weight of each satellite can be increased.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

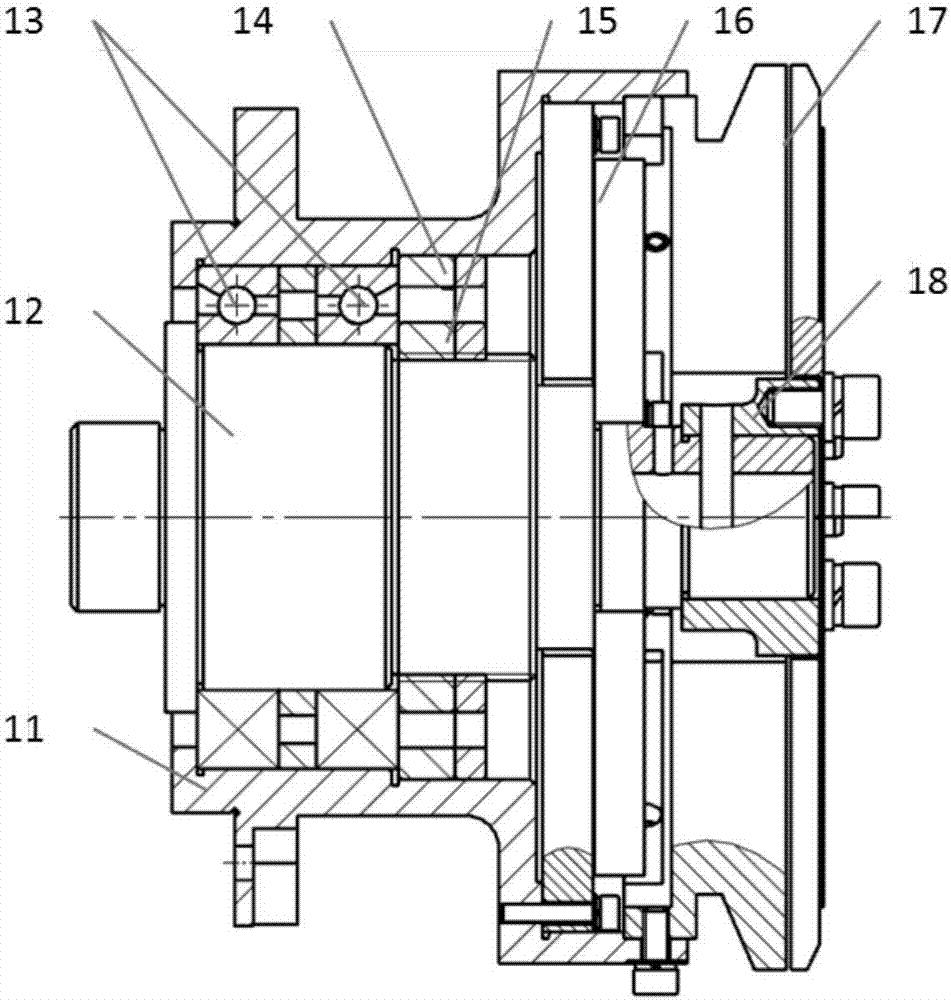

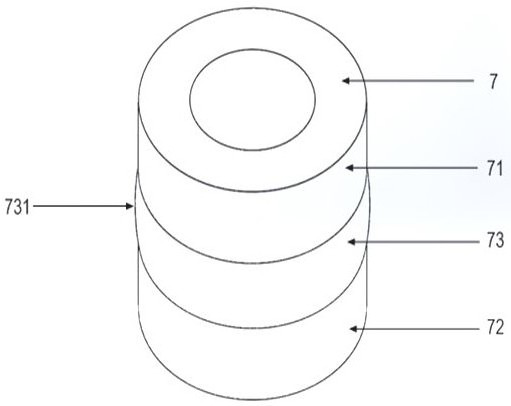

Vehicle-mounted magnetic suspension flywheel energy storage system with torsional gyroscopic effect suppression

ActiveCN110011469ASmall disturbance torqueReduce axial sizeMechanical energy handlingMagnetic bearingDegrees of freedom

The invention discloses a vehicle-mounted magnetic suspension flywheel energy storage system with a torsional gyroscopic effect suppression. The system comprises a five-degree-of-freedom magnetic bearing, a flywheel rotor and an outer rotor motor which are coaxially arranged, wherein the middle section of the flywheel rotor is a flywheel rotor main cylinder, the lower section is a lower end circular ring, the external part of the upper section of the flywheel rotor is an upper end circular ring, the middle of the upper section is an inner receiving pole, the lower section is a lower end circular ring, the inner receiving pole is of a hemispherical structure, the inner diameter of the upper end circular ring is greater than the inner diameter of the lower end circular ring, the diameter ofthe inner receiving pole is less than the inner diameter of the lower end circular ring, a circular ring-like groove is formed among the flywheel rotor main cylinder, the inner receiving pole and theupper end circular ring, the five-degree-of-freedom magnetic bearing is arranged in the circular ring-like groove, a cylindrical groove is formed between the flywheel main cylinder and the lower end circular ring, and the outer rotor motor is arranged in the cylindrical groove. The system is supported by adopting the unilateral highly integrated five-degree-of-freedom magnetic bearing, which reduces the axial size and suppresses the torsional gyroscopic effect.

Owner:JIANGSU UNIV

Satellite orbit control engine installation optimization method based on genetic algorithm

ActiveCN103984785AExcellent installation parametersOptimal determination methodGenetic modelsSpecial data processing applicationsControl systemGenetic algorithm

The invention provides a satellite orbit control engine installation optimization method based on a genetic algorithm. The method comprises the following steps that (1) an objective function of the engine installation optimization is determined according to the requirement of a control system on the satellite layout; (2) according to the engine geometrical parameters and the installation requirements, a constraint function of the engine installation optimization is determined; (3) an AMTLB genetic algorithm toolkit is used for carrying out engine installation parameter optimization. The satellite orbit control engine installation optimization method has the advantages that the interference moment in the orbital transfer period is further reduced, so the satellite fuel is saved, and the satellite on-orbit life is prolonged.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

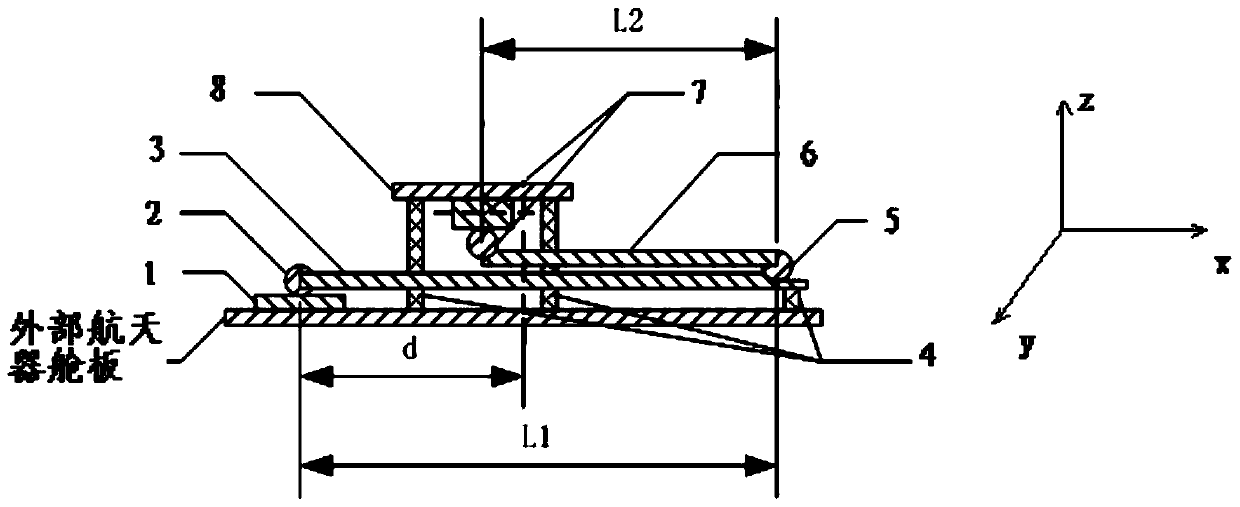

Two-dimensional directing mechanism for optical remote sensing instrument

ActiveCN107218960AImprove pointing accuracyLong axis decreaseMeasurement apparatus componentsGear wheelEngineering

The invention discloses a two-dimensional directing mechanism for an optical remote sensing instrument. The two-dimensional directing mechanism comprises an upper half shaft assembly, a lower half shaft assembly, a left half shaft assembly, a right half shaft assembly, a directing mirror assembly, an inner frame, an outer frame, a support frame and a counterweight. The lower half shaft assembly and the left half shaft assembly have the same structure. The upper half shaft assembly and right half shaft assembly have the same structure. The upper half shaft assembly, the lower half shaft assembly and the inner frame constitute a pitch axis system. The left half shaft assembly, the right half shaft assembly, the outer frame and the pitch axis system form an azimuth axis system. The two-dimensional directing mechanism is high in directing precision, light in weight, low in moment of inertia, small in interference torque of satellite platform, compact in structure, simple in structure, and directly driven to avoid a complex harmonic reducer or gear reduction mechanism, and highi in reliability.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

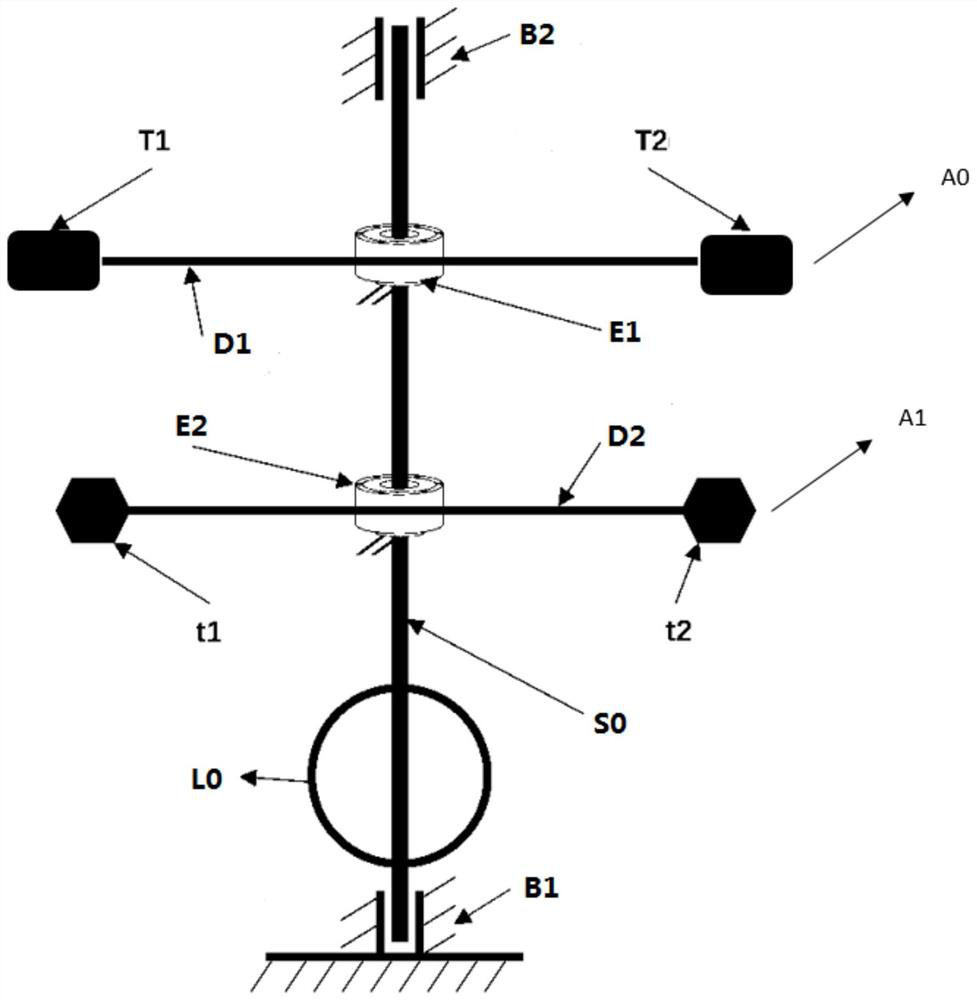

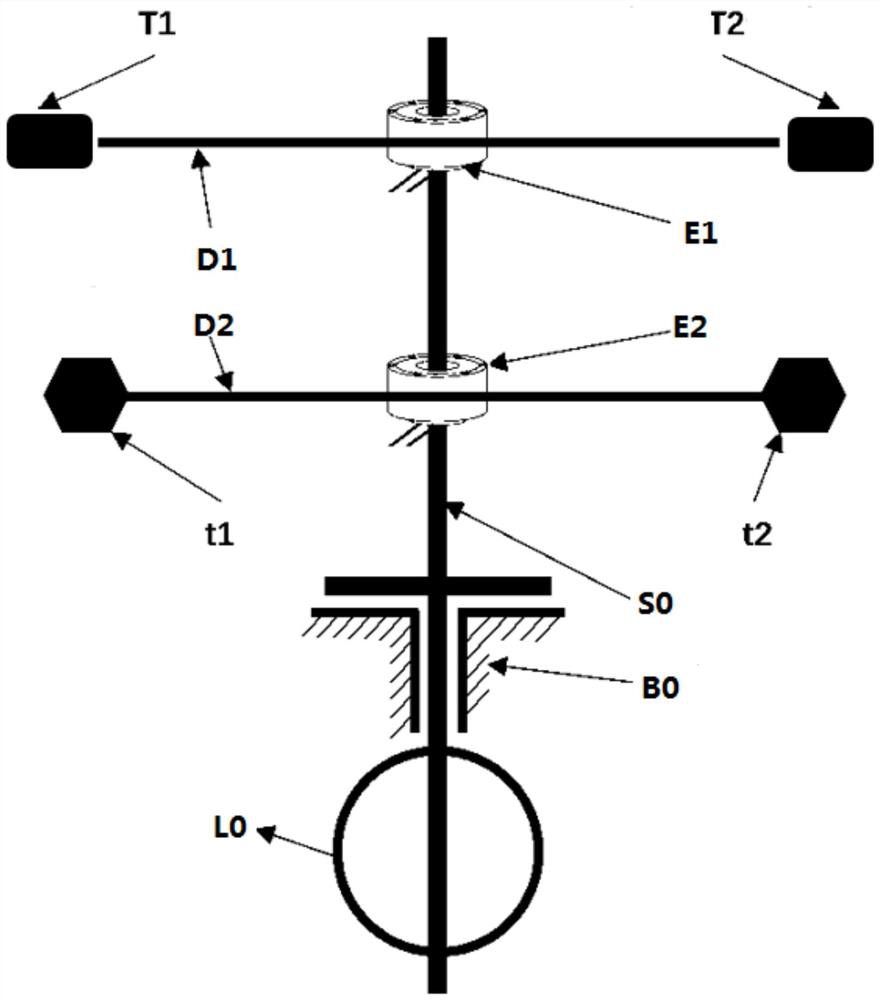

Coaxial contra-rotating terrestrial magnetism energy storage and release delivery ground experiment system and method

ActiveCN113075592AReduce power consumptionSmall sizeCosmonautic condition simulationsThree-component magnetometersTarget reachingMechanical engineering

The invention discloses a coaxial contra-rotating terrestrial magnetism energy storage and release delivery ground experiment system, which comprises a supporting through shaft and a magnetic moment generation device, and is characterized in that a first target delivery assembly and a second target delivery assembly are coaxially and rotatably mounted on the supporting through shaft, and are both used for mounting and releasing a delivery target; the working method comprises the steps that the first target delivery assembly and the second target delivery assembly are configured to receive a rotation starting signal of the magnetic moment generation device, then rotate oppositely with the supporting through shaft as a rotating shaft, and when the linear speed of a delivery target reaches the linear speed set by the system, the first target delivery component or the second target delivery component releases the delivery target. According to the invention, two sets of delivery devices rotate coaxially and oppositely, so that the air resistance moment in a ground experiment can be overcome, and the restriction that the target linear velocity has an upper limit is relieved, thereby being better used for ground principle verification of a terrestrial magnetism energy storage method.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI +1

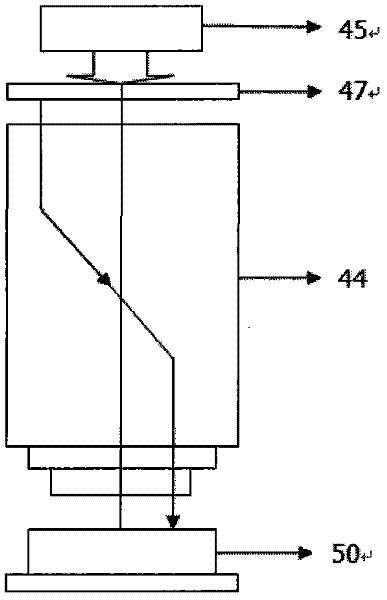

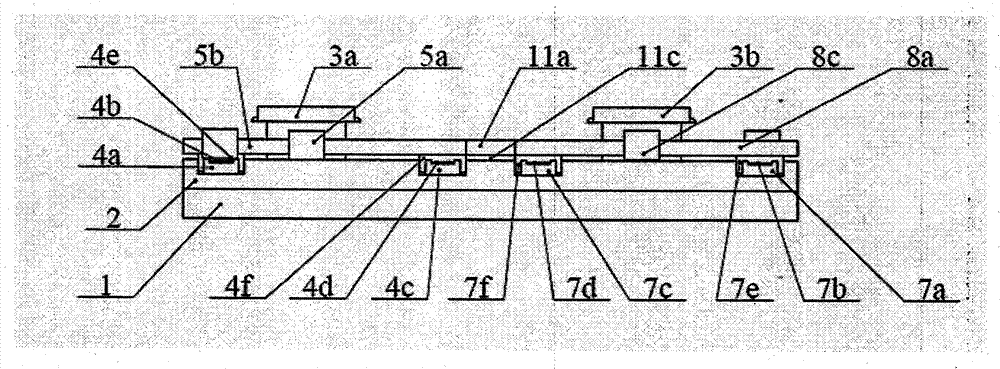

Device and method for exchanging of double workpiece tables on lintel type single/double guide rails in double-drive stepping scanning

InactiveCN102393609AGreat driving forceSmall inertiaPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistEngineering

A device and a method for exchanging of double workpiece tables on lintel type single / double guide rails in double-drive stepping scanning belong to semiconductor manufacturing equipment. The system comprises a silicon wafer table running at an exposure station and a silicon wafer table running at a pretreatment station, and the two silicon wafer tables are arranged on a same base table. Four linear movement units in the Y direction and two linear movement units in the X direction are arranged at the edge of the base table; two lintel type linear movement units higher than the working surface of the silicon wafer table in the X direction are arranged in the middle of the base table; and the linear movement in the X direction of the linear movement units in the Y direction can be realized by the linear movement units in the X direction, and the linear movement units in the Y direction and movement sliders of the movement units in the Y direction can realize the movement of the silicon wafer table in the X direction or in the Y direction. The device and the method can improve the torque interference resisting capacity of the guide rail and reduces or overcomes movement deviation and deformation deviation due to the interference of torque, thereby enhancing the movement precision of the silicon wafer table. The table exchanging process only needs three beats, so that the time for exchanging the double tables is shortened, and the production efficiency of a lithography machine is enhanced obviously.

Owner:HARBIN INST OF TECH

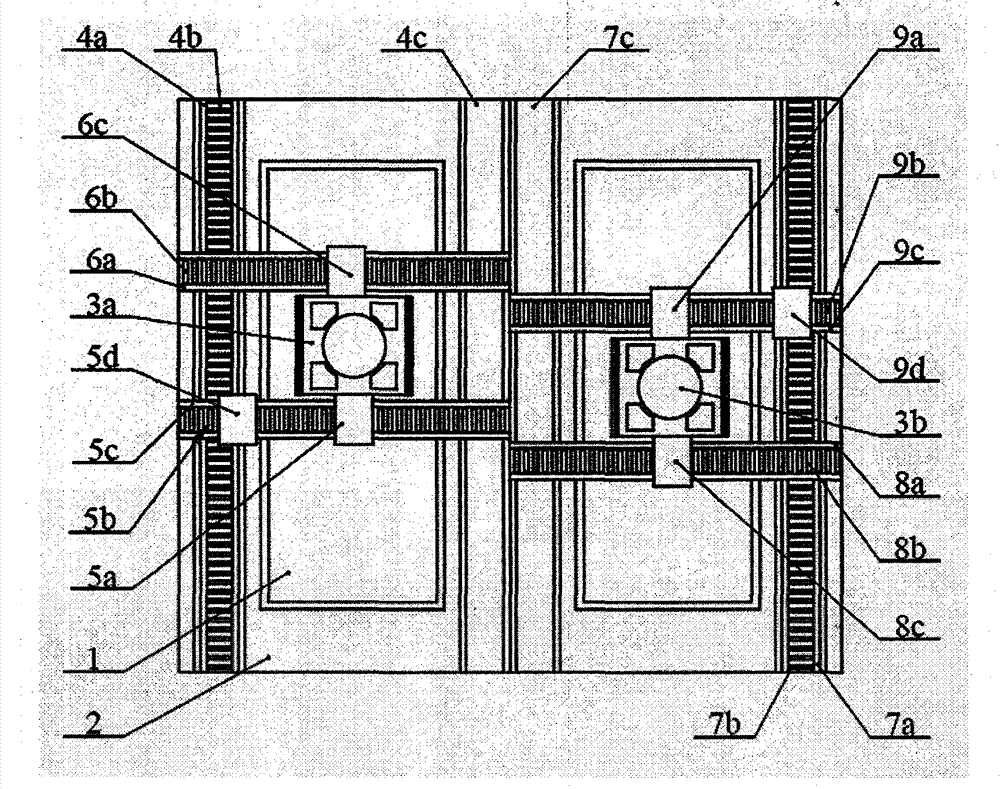

Double-rail double-drive-based three-beat double-workpiece bench exchange apparatus and method thereof

InactiveCN102393612AGreat driving forceSmall qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistButt joint

The invention which relates to a double-rail double-drive-based three-beat double-workpiece bench exchange apparatus and a method thereof belongs to the technical field of semiconductor manufacturing equipment. The apparatus is characterized in that: the apparatus comprises workpiece benches which operate on a prealigned station and an exposure station; the prealigned station and the exposure station are respectively provided with a well type driving unit which comprises a two side X-directional liner motion unit and a two side Y-directional liner motion unit; two Y-directional transitional liner motion units are arranged between the two well type driving units; and the bench replacement of the double-workpiece bench is completed through the butt joint of the Y-directional liner motion unit and the X-directional liner motion unit. According to the invention, the two workpiece benches are driven in the prealigned station and the exposure station in a dual side mass center mode, so the system angle rigidity is increased; only three beats are needed to exchange the two workpiece benches between the prealigned station and the exposure station, so the lithography efficiency is improved; and the apparatus has the advantages of small motion inertial, short stable time, large structure rigidity and the like in the concrete embodiment process.

Owner:HARBIN INST OF TECH

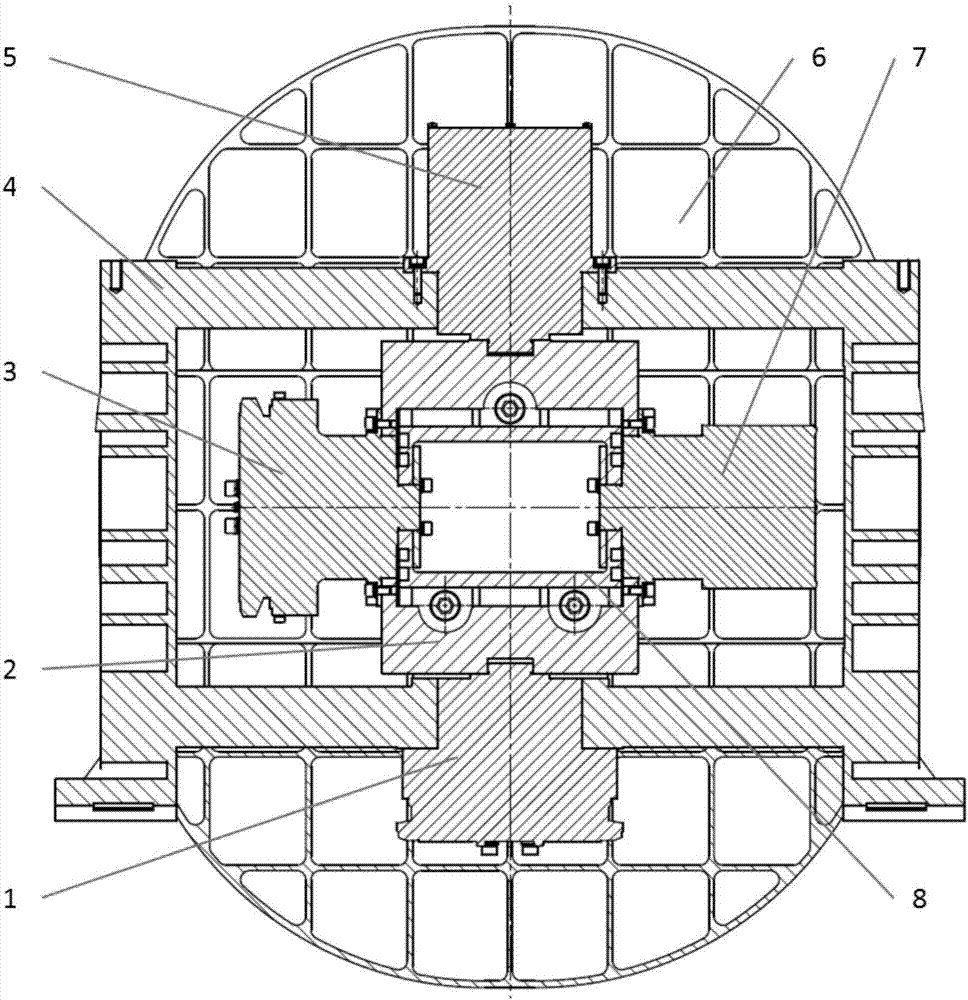

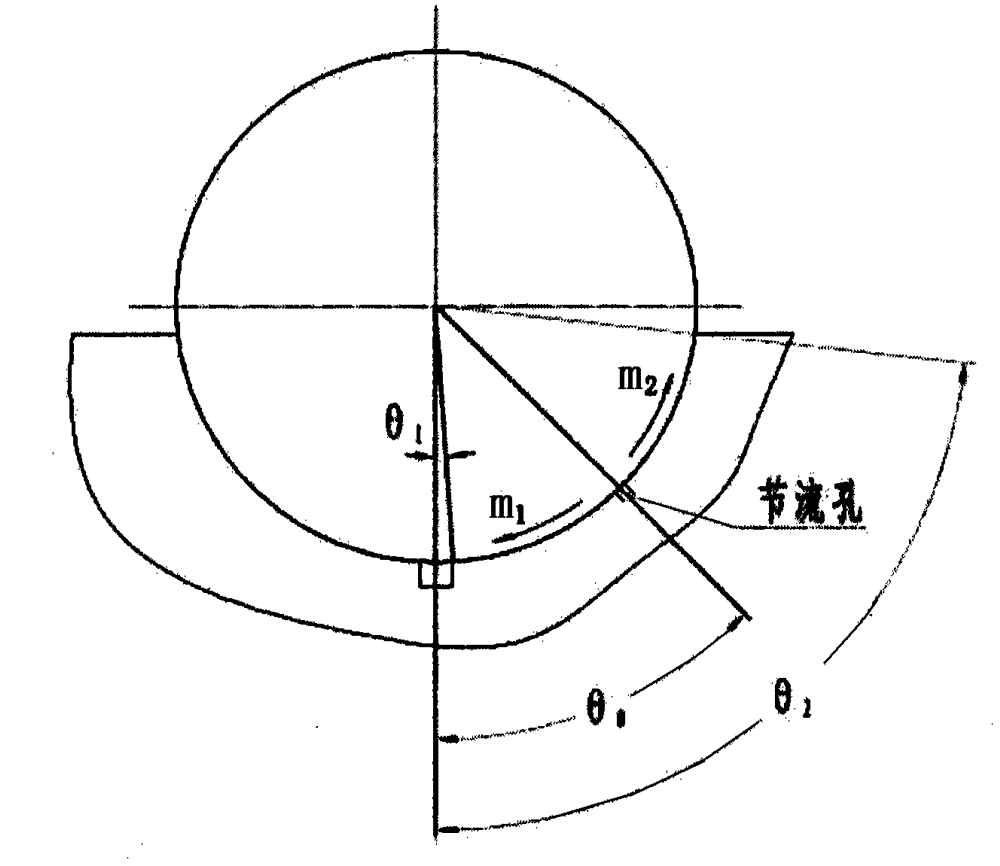

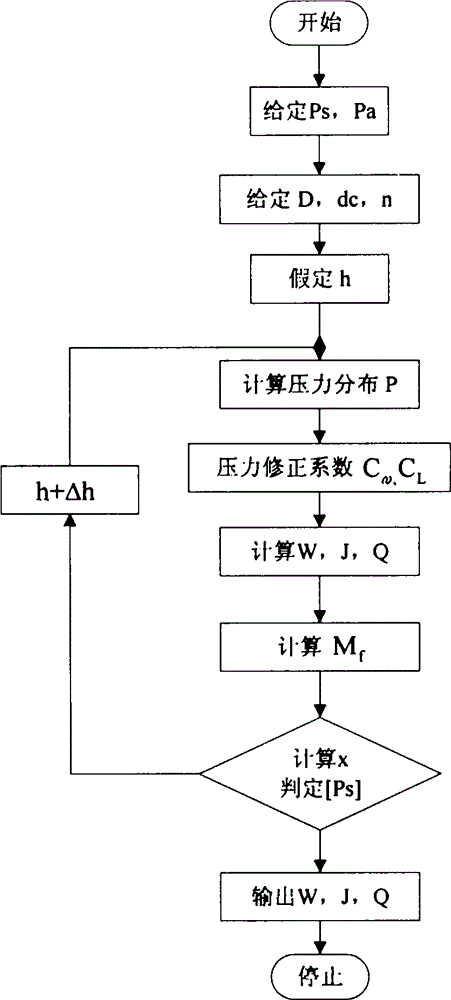

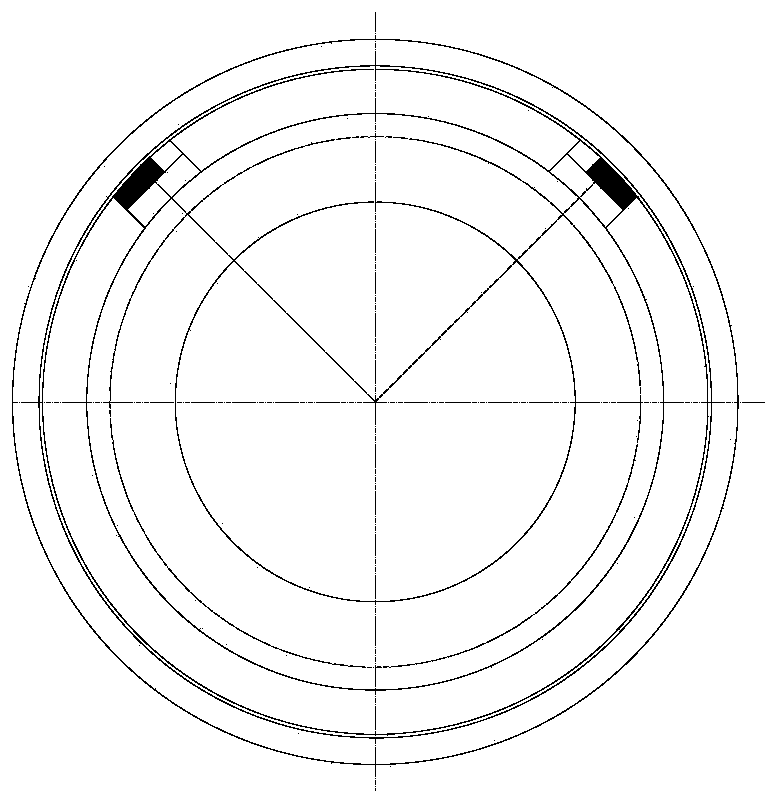

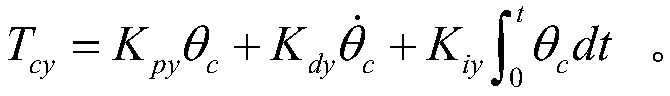

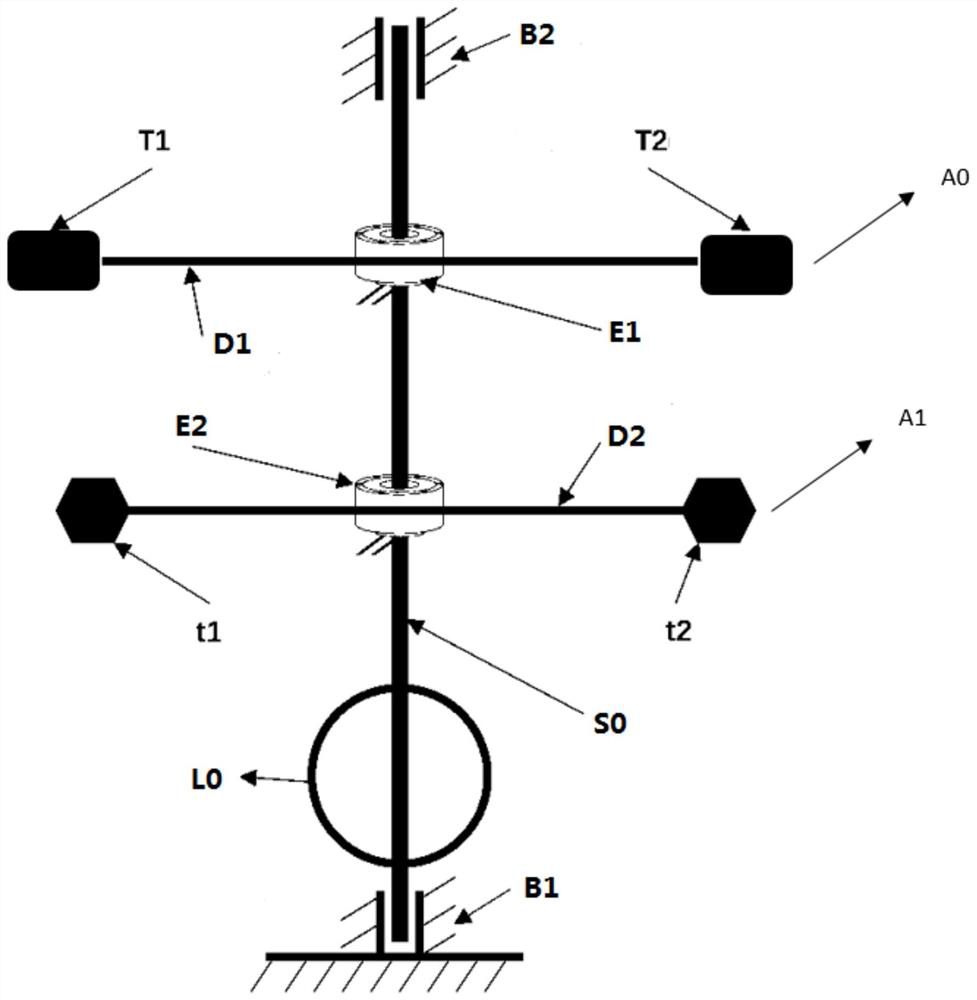

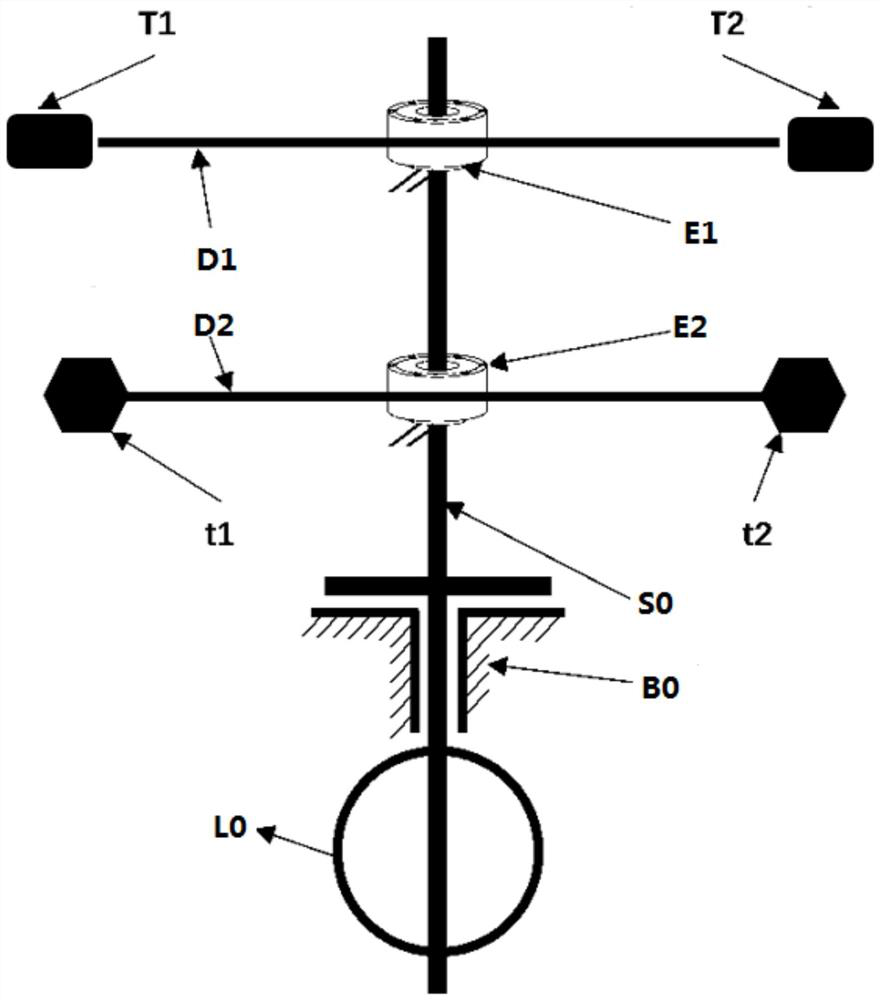

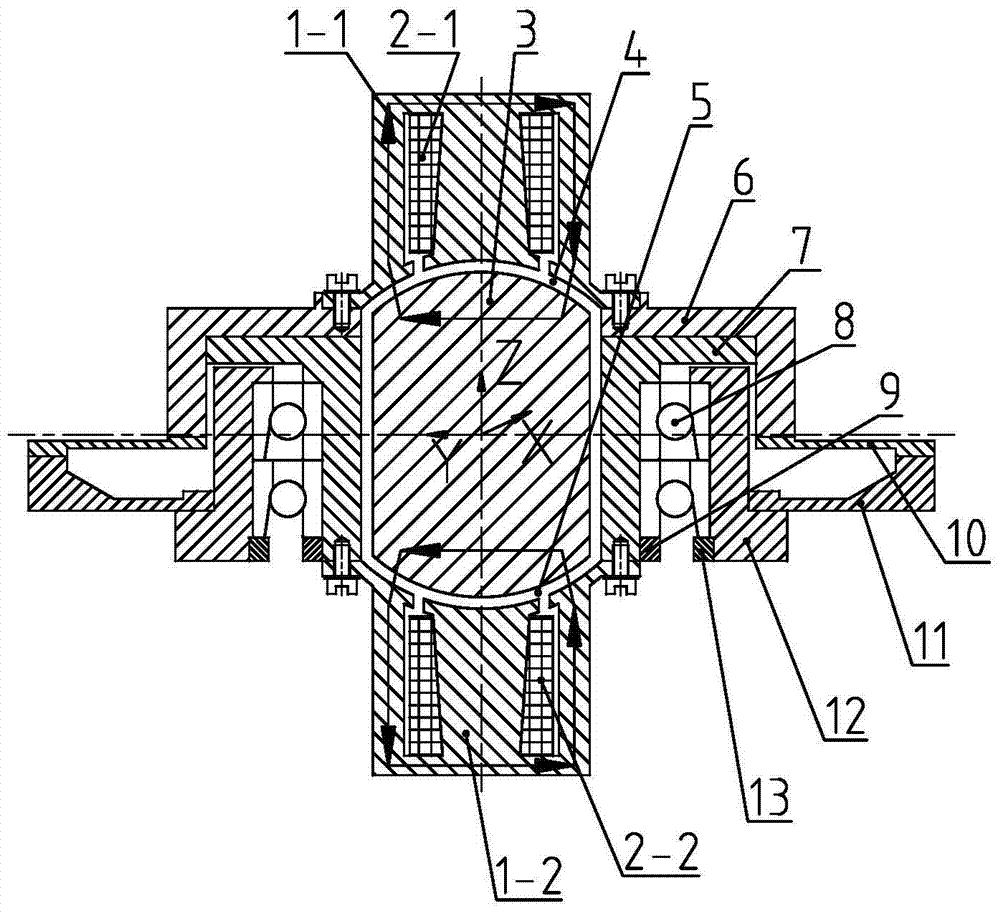

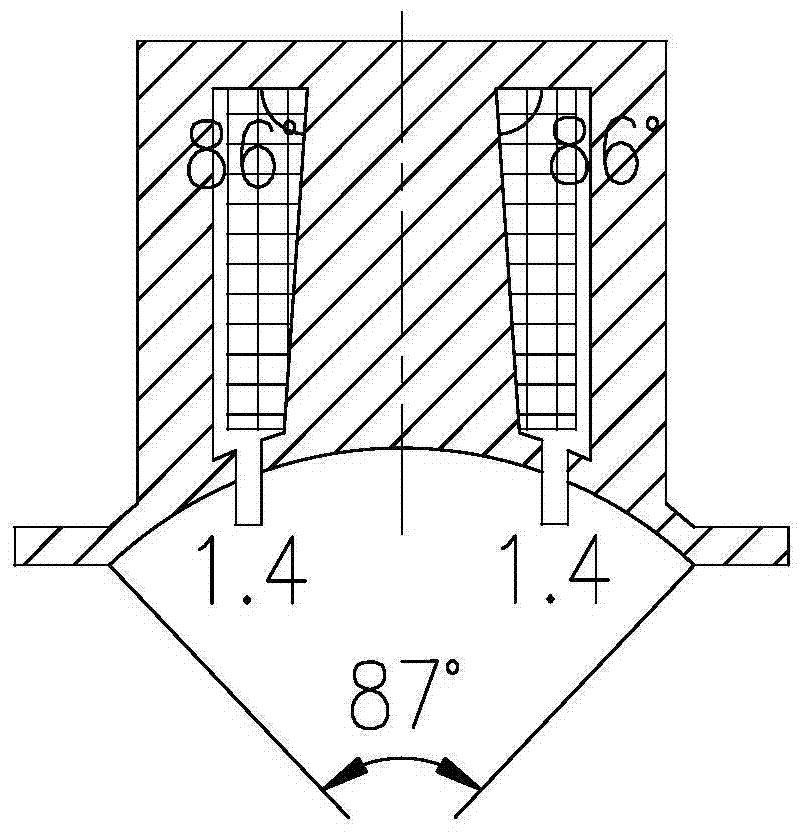

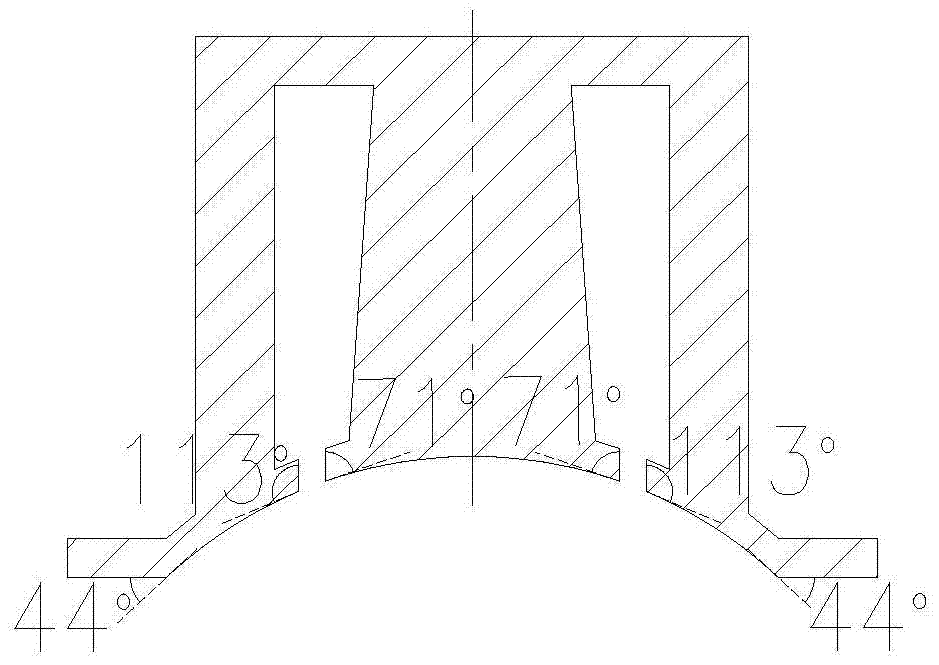

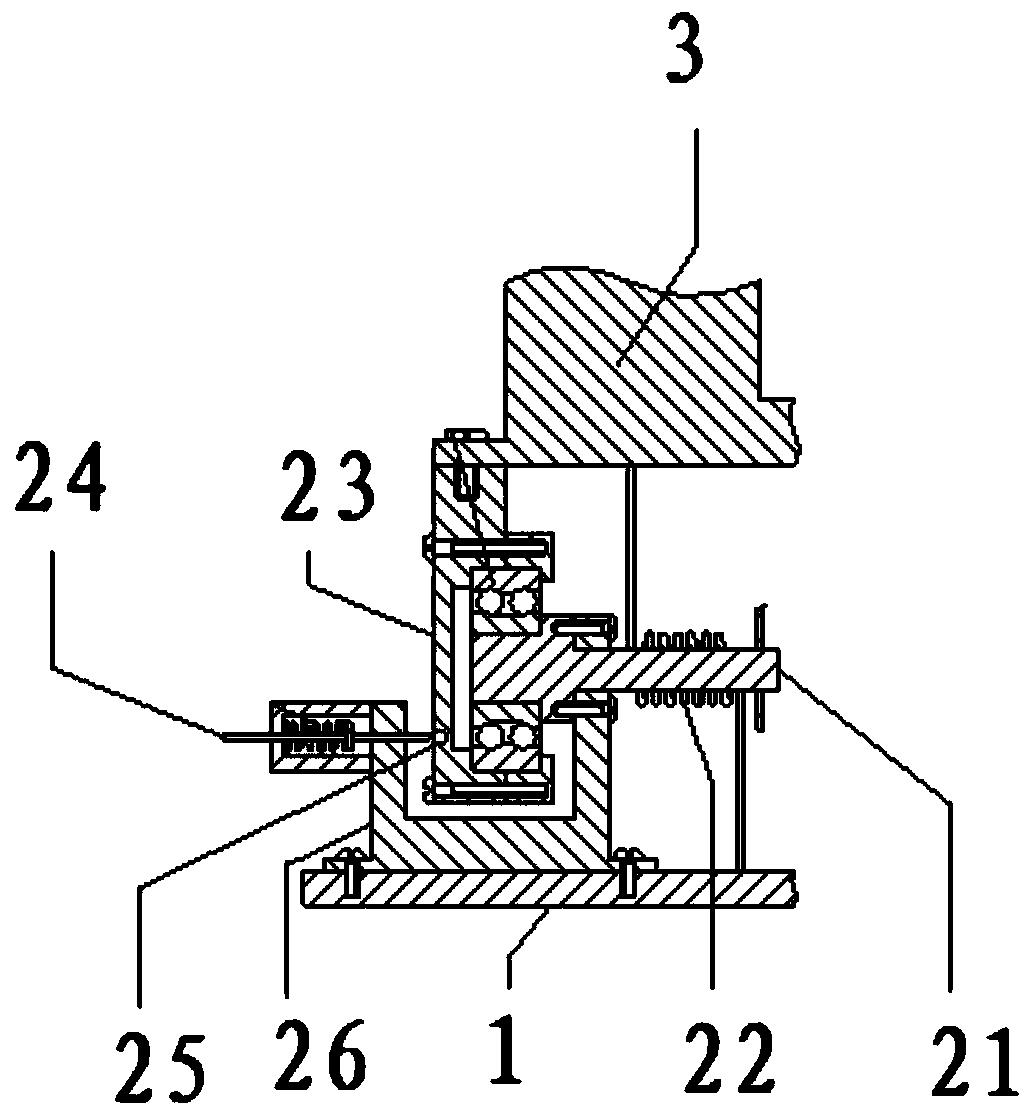

High-stability low-disturbance torque optimum design method of triaxial air bearing table

ActiveCN104318024AReduce processing difficultySmall disturbance torqueSpecial data processing applicationsThermodynamicsAir bearing

The invention provides a high-stability low-disturbance torque optimum design method of a triaxial air bearing table. According to the arrangement, indexes such as loading capacity, air supply pressure, thickness of air film, rigidity of the air film and a throttler of a ball bearing of the triaxial air bearing table are calculated for optimization and iteration, and the final design plan with optimal rigidity of the air film is obtained. In this way, production difficult is decreased in design, with factor of air source fluctuation considered, high stability and low disturbance torque of the system are guaranteed in design, and project realization is facilitated. The optimum design method is suitable to optimization design of a homotaxial air bearing table and is high in precision and stability, low in cost and applicable to engineering application of ground development of various high-precision spacecrafts.

Owner:HARBIN INST OF TECH

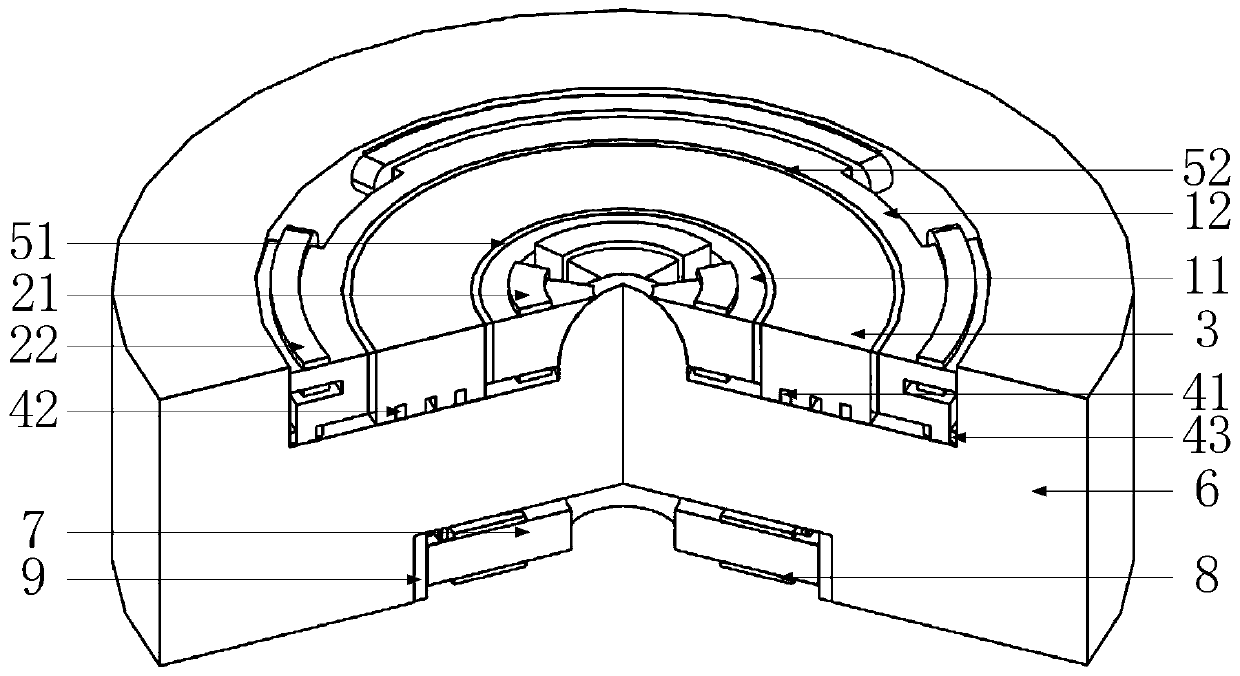

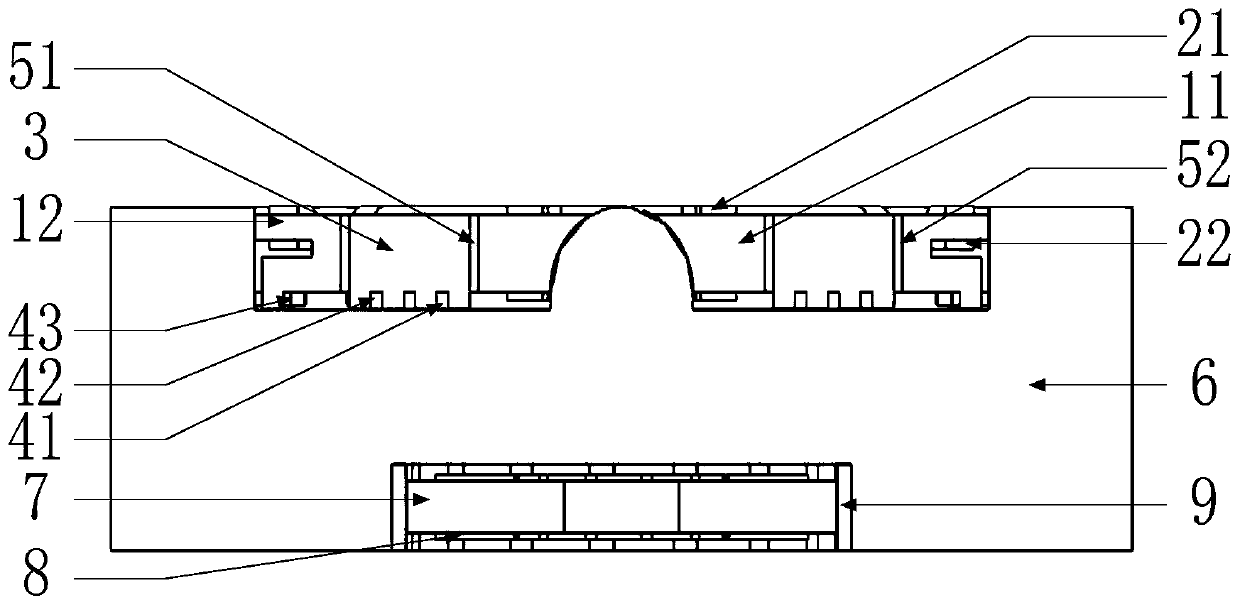

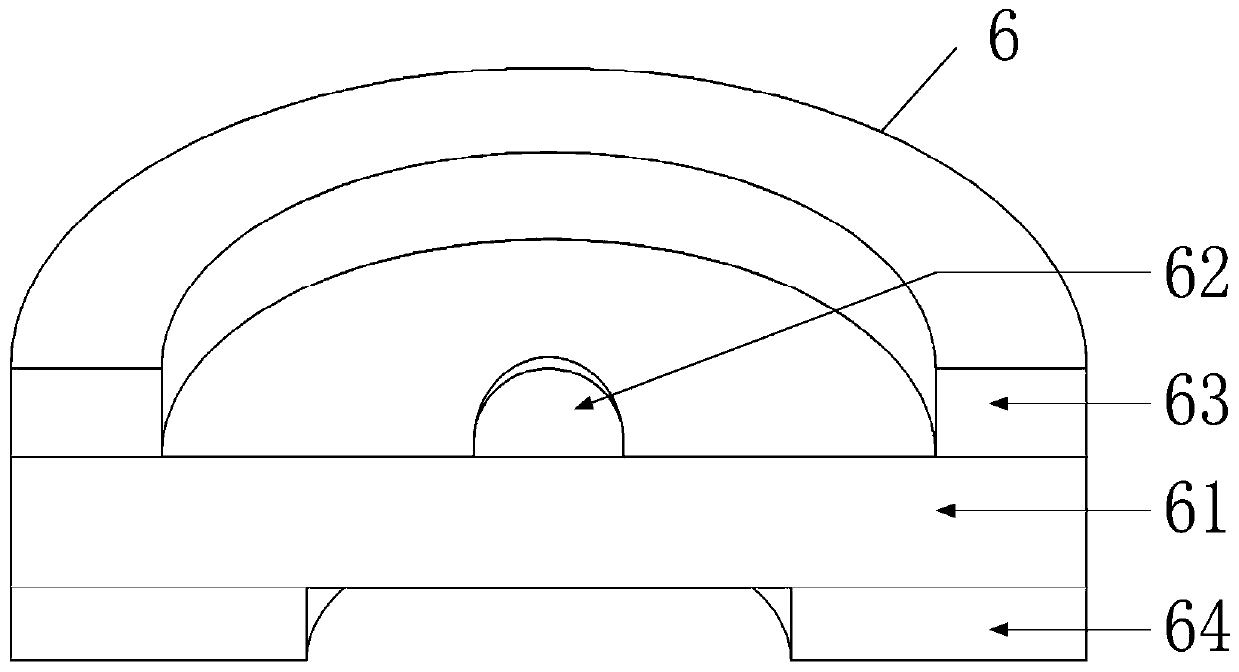

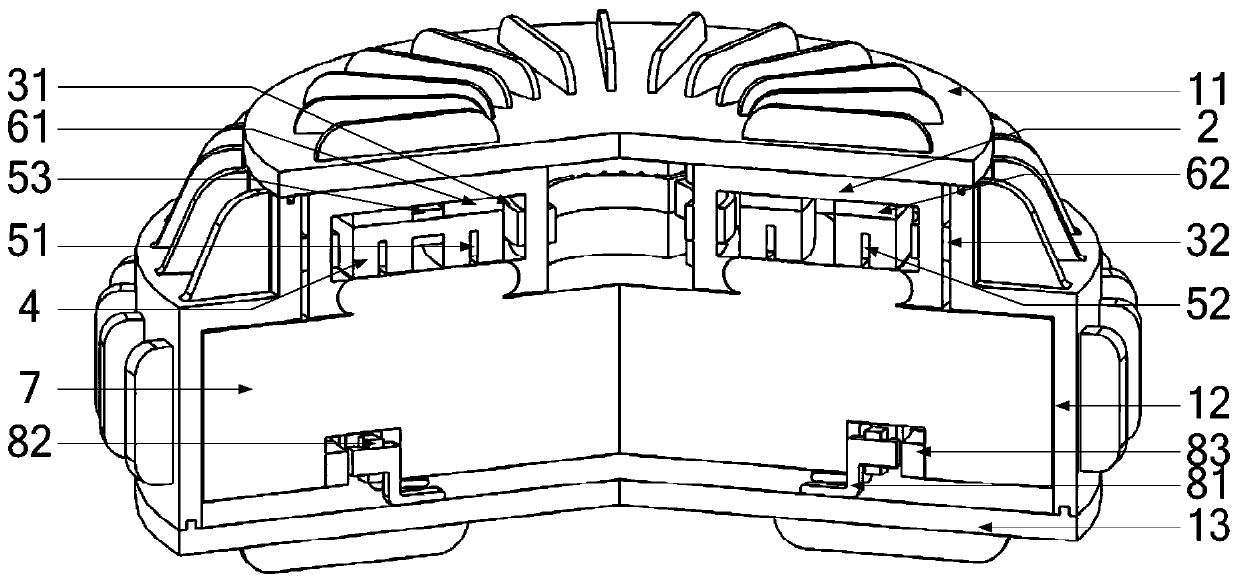

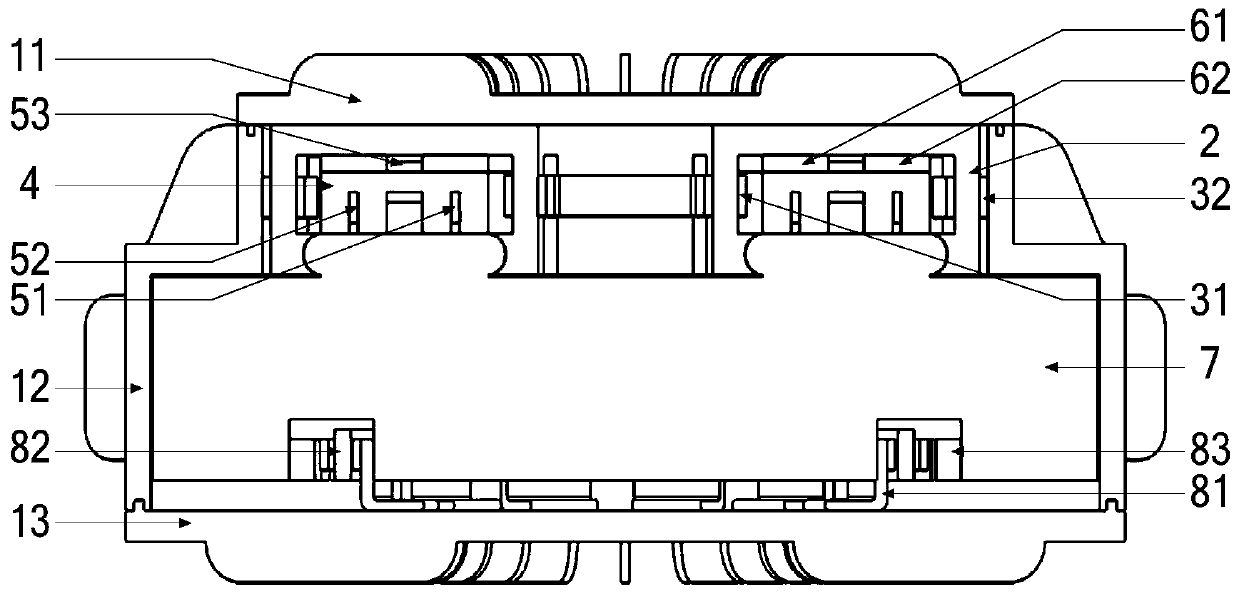

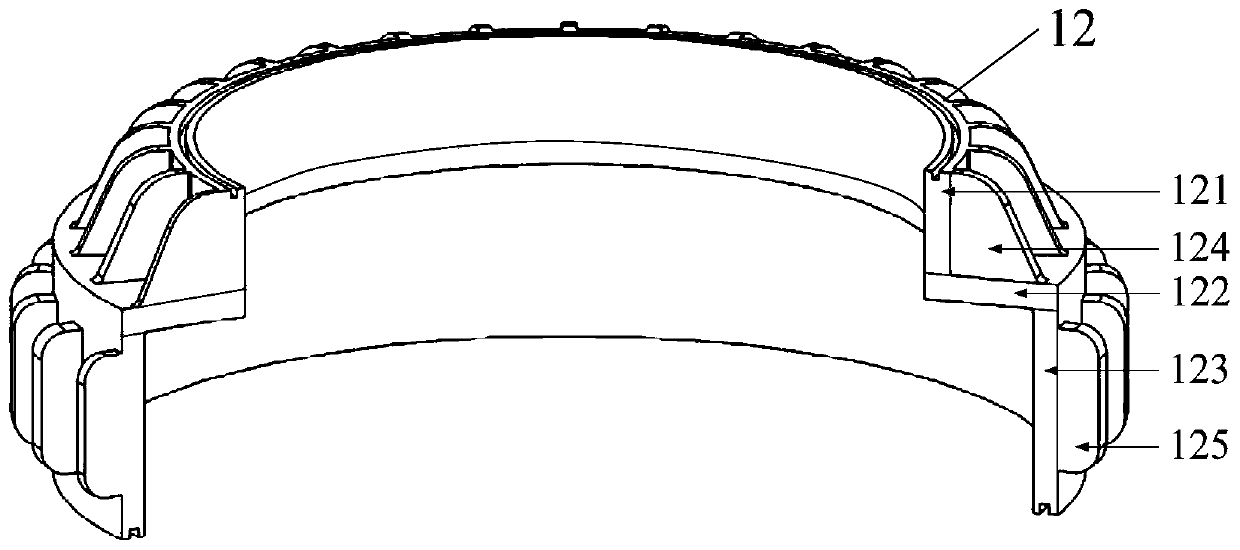

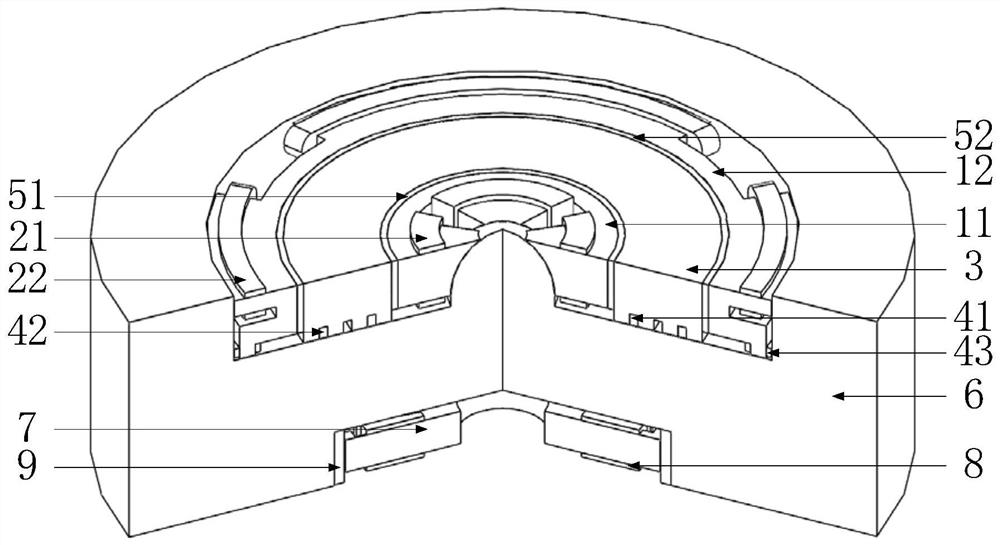

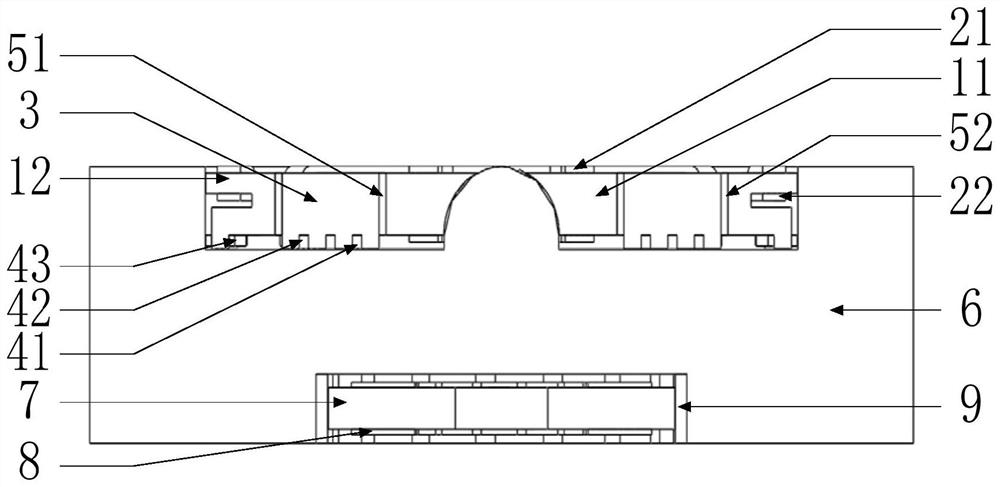

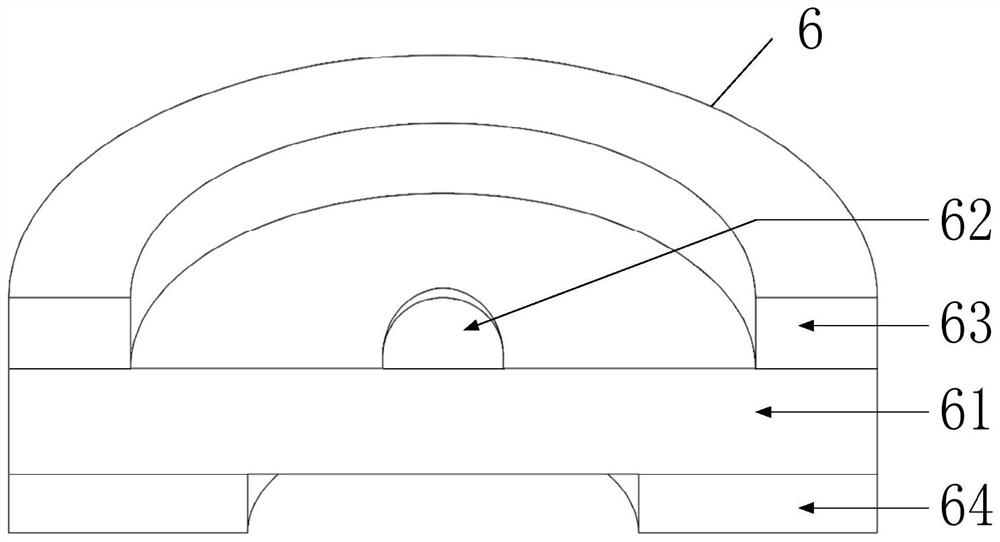

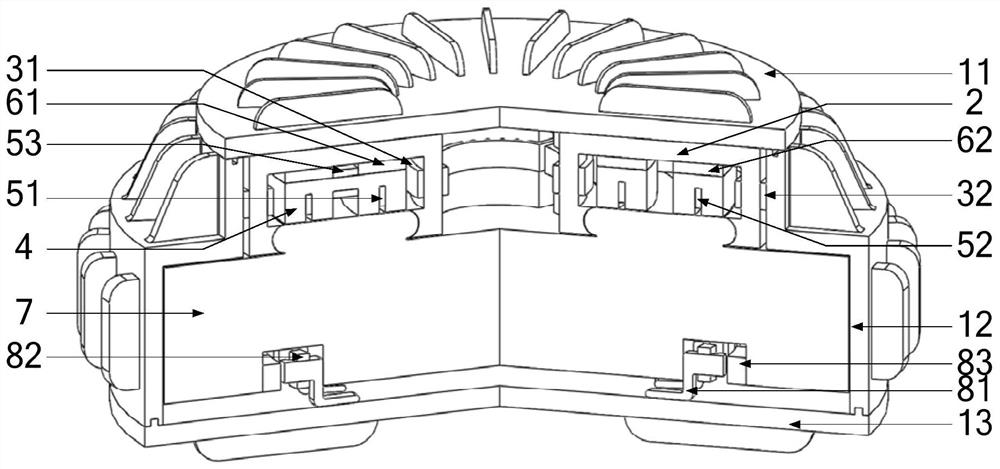

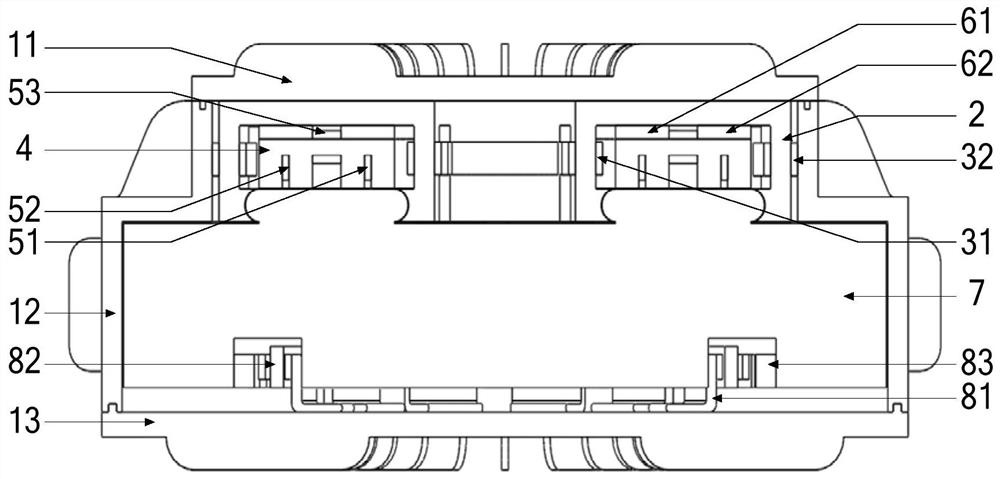

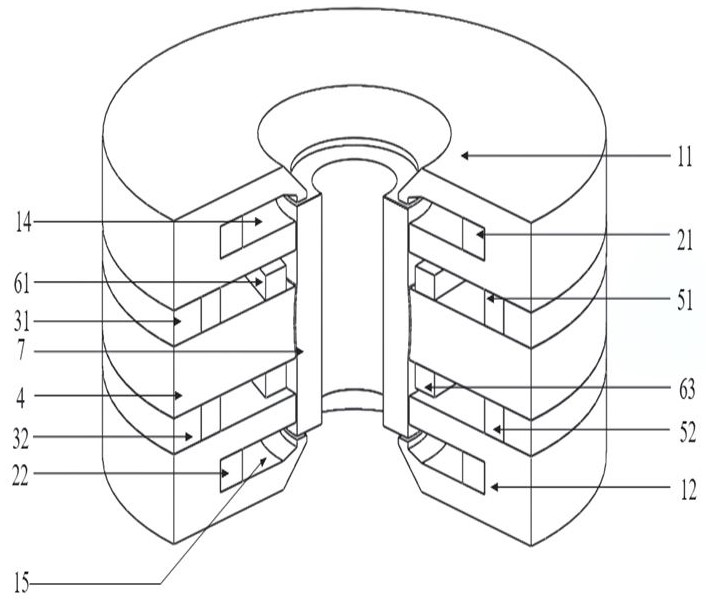

Five-degree-of-freedom single-side suspension supported ball flywheel integrated vehicle-borne energy storage device

ActiveCN110112860AReduce axial sizeSuppress gyro effectElectric machinesMechanical propulsion powerMagnetic bearingDegrees of freedom

The invention discloses a five-degree-of-freedom single-side suspension supported ball flywheel integrated vehicle-borne energy storage device for an electric vehicle. The middle part of a flywheel rotor is a main disc body, the upper part is a spherical ring, the lower part is an outer ring and an inner disc, a circular groove is formed between the inner disc and the outer ring, and an outer rotor motor is in the circular annular groove. A circular outer wall of the spherical ring is an outwardly convex spherical surface, and an inner wall is an inwardly convex spherical surface. The uppermost end of a radial stator of a five-degree-of-freedom magnetic bearing is an upper end ring of a ring body, a radial outer ring stator yoke extends downward from an outer side wall of an upper end ring, a radial inner ring stator yoke extends downward from an inner side wall, a spherical groove is formed between inner side walls of a radial outer ring stator pole extending inward from an inner sidewall of a lower end of the radial outer ring stator yoke, a spherical groove is formed between inner side walls of a radial inner ring stator pole extending outward from an outer side wall of a lowerend of the radial inner ring stator yoke, and the spherical ring sleeves the radial inner ring stator pole and the radial outer ring stator pole, the axial dimension is reduced, and the gyro effect is suppressed.

Owner:JIANGSU UNIV

A vehicle-mounted magnetic levitation flywheel energy storage system with suppressed torsion gyro effect

ActiveCN110011469BSmall disturbance torqueReduce axial sizeMechanical energy handlingMagnetic bearingIn vehicle

Owner:JIANGSU UNIV

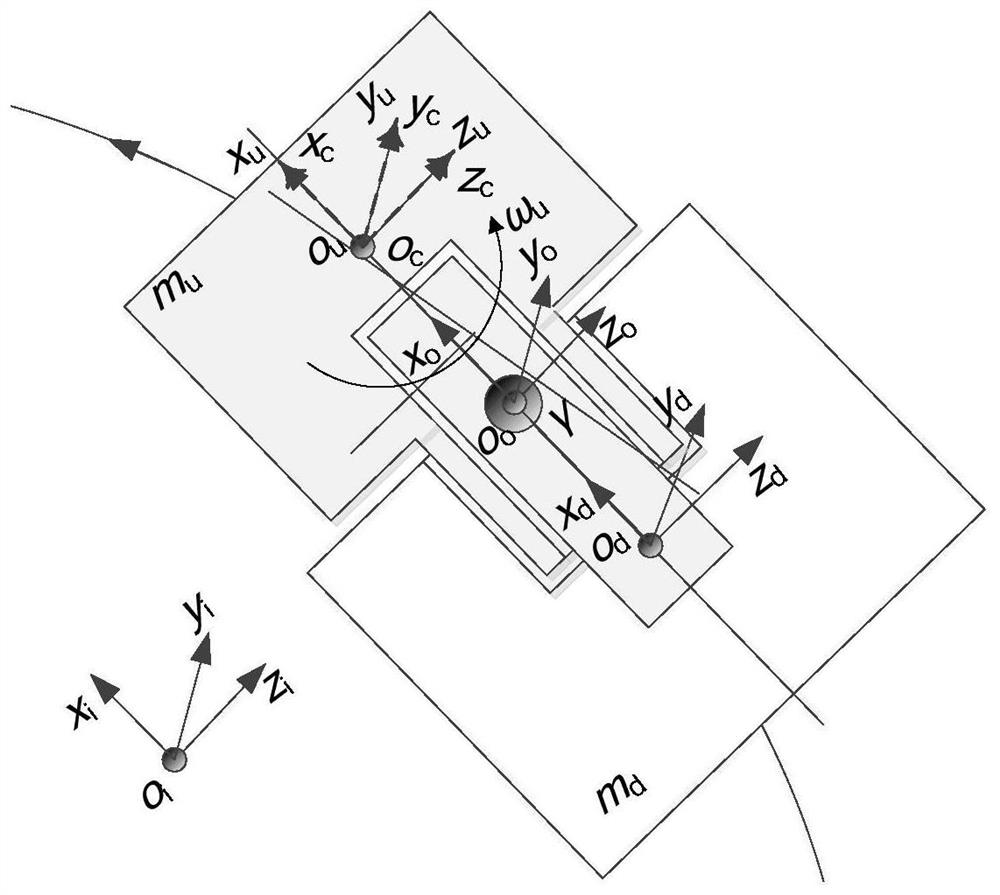

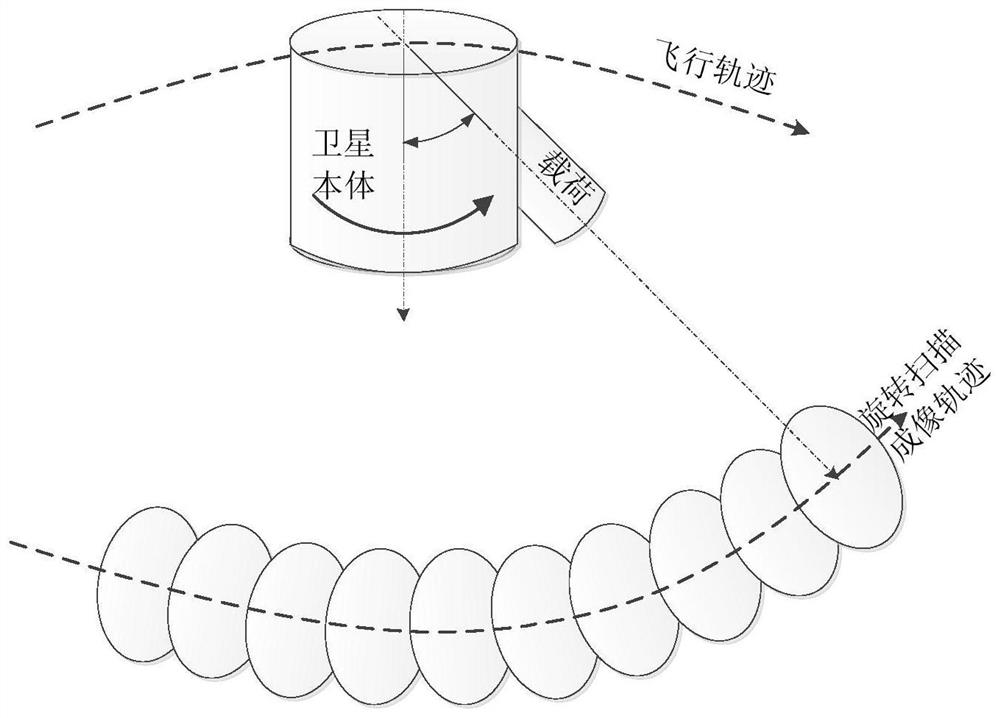

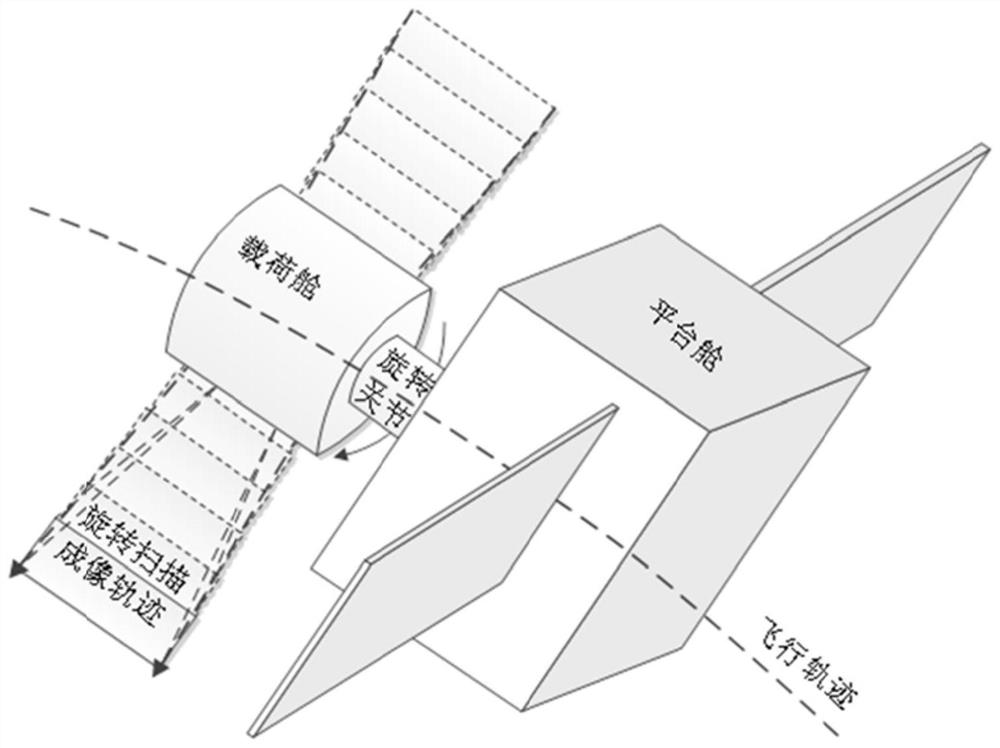

Method and system for estimating disturbance torque caused by asymmetric rotational scanning load

ActiveCN113031668ASmall disturbance torqueSmall moment of inertiaMechanical power/torque controlSustainable transportationEuler equationsDynamic models

The invention discloses a method and a system for estimating disturbance torque caused by an asymmetric rotational scanning load. The method comprises the following steps of: calculating according to coordinate conversion to obtain a rotational inertia matrix of a rotating body formed by a load cabin and a magnetic suspension joint rotor in an orbital coordinate system; calculating to obtain the angular velocity vector of the rotating body in the inertial coordinate system; calculating the angular momentum of the load cabin according to the rotational inertia matrix and the angular velocity vector of the rotating body; establishing the attitude dynamic model of the rotating body according to an Euler equation; classifying nominal rotating speeds in the attitude dynamical model to obtain a variable inertia reaction torque and gyroscopic torque interference model caused by an orbital angular velocity and a rotating body angular velocity; and substituting the rotational inertia of the rotating body in the satellite and the nominal rotating speed of the rotating body into the interference model, and estimating constant value, first frequency multiplication and second frequency multiplication interference torques caused by the rotating body. According to the invention, a basis for applying interference is provided for control, ground simulation and test verification of the magnetic suspension rotary joint and the satellite.

Owner:BEIJING INST OF CONTROL ENG

Lintel type dual-guide rail dual-drive stepping scanning double silicon wafer stage exchanging device and method thereof

InactiveCN102495529AGreat driving forceSmall qualitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusInterference resistanceEngineering

The invention relates to a lintel type dual-guide rail dual-drive stepping scanning double silicon wafer stage exchanging device and a method thereof, and belongs to the field of semiconductor manufacturing equipment. According to the device, the system comprises two silicon wafer stages arranged on the same base station, wherein one silicon wafer stage operates at the exposure working position, and the other silicon wafer stage operates at the pretreatment working position; the edge of the base station is provided with 4 Y-direction linear movement units and 2 X-direction linear movement units; the middle of the base station is provided with 2 lintel type linear movement units, wherein the X directions of the lintel type linear movement units are higher than the working surfaces of the silicon wafer stages; the Y-direction linear movement units can perform the movements in the X direction through the X-direction linear movement units, and can collectively perform the movements of thesilicon wafer stages in the X direction or in the Y direction with Y-direction movement sliders of the Y-direction linear movement units. According to the present invention, the torsion interference resistance of the guide rail can be enhanced, the movement deviation and the deformation deviation can be decreased or overcome, and the movement precision of the silicon wafer stage can be improved; the operation of the device of the present invention only comprises three steps so as to shorten the required double stage exchanging time, and significantly improve the production efficiency of the photoetching machine.

Owner:HARBIN INST OF TECH

Three-degree-of-freedom spherical hybrid magnetic bearing with axial self-loop

ActiveCN108547867AGood for high speed operationIncrease speedShaftsEngine componentsMagnetic bearingThree degrees of freedom

The invention discloses a three-degree-of-freedom spherical hybrid magnetic bearing with an axial self-loop. An outer axial stator, an upper annular permanent magnet, a radial stator, a lower annularpermanent magnet and a lower axial stator sequentially coaxially sleeve a rotator from top to bottom, each of the upper axial stator and the lower axial stator is formed by axially connecting an upperdisc, a middle disc and a receiving disc, the inner end surface of every upper disc extend radially inwards extends to form a conical disc, small discs are arranged between the upper and lower end surfaces of the rotor and the corresponding conical discs, the small discs are closely attached to the upper and lower surfaces of the corresponding conical discs, the upper small disc is located abovethe upper end surface of the rotor, and the lower small disc is located below the lower end surface of the rotor; and axial air gaps are left between the upper and lower small disks and the end surface of the rotor, and a control magnetic flux enters the receiving discs through return air gaps to axially form the self-loop without mounting a pushing disc, so the rotating speed of the rotor is optimized, and coupling of axial and radial magnetic fields is reduced.

Owner:JIANGSU UNIV

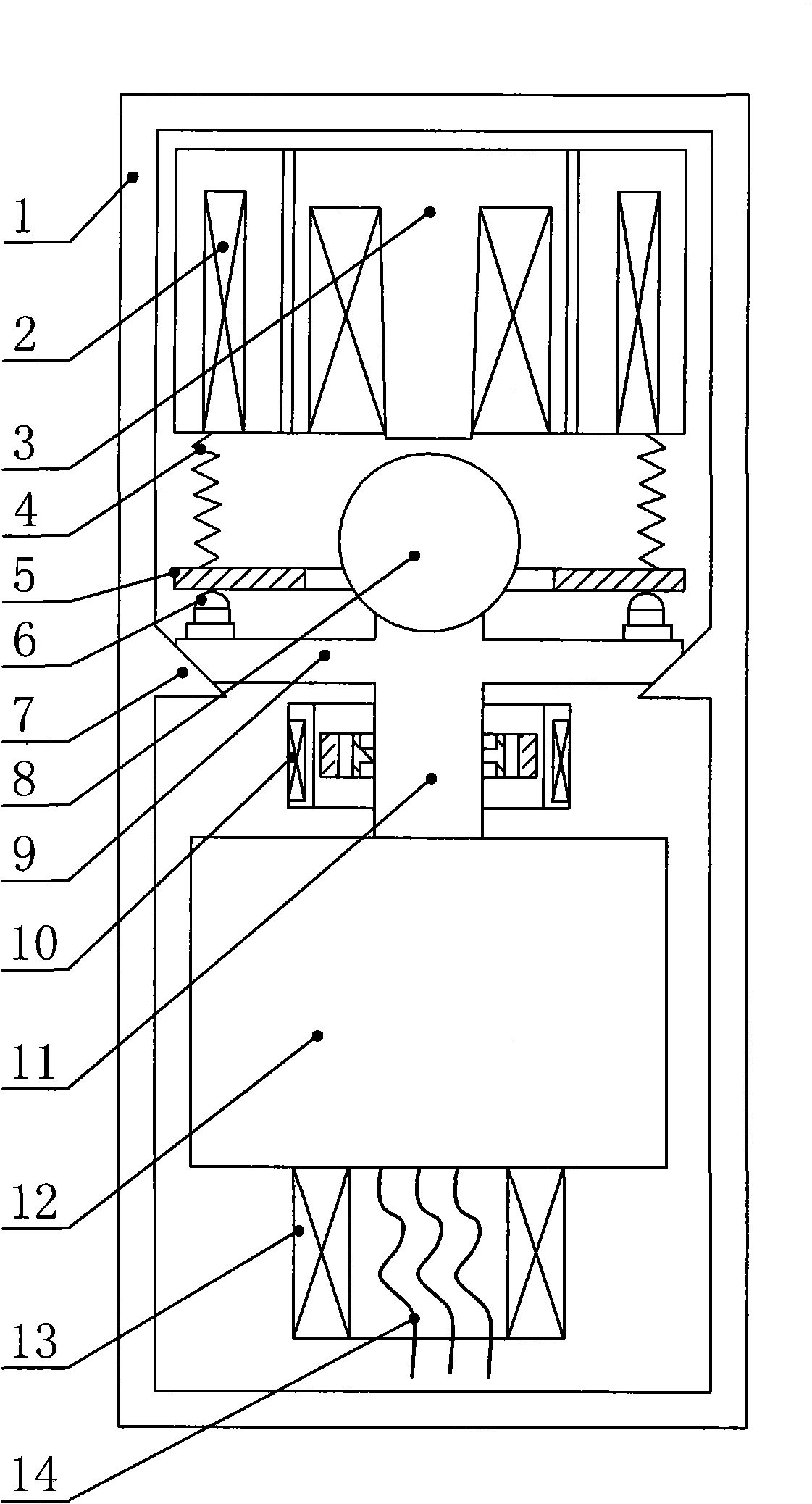

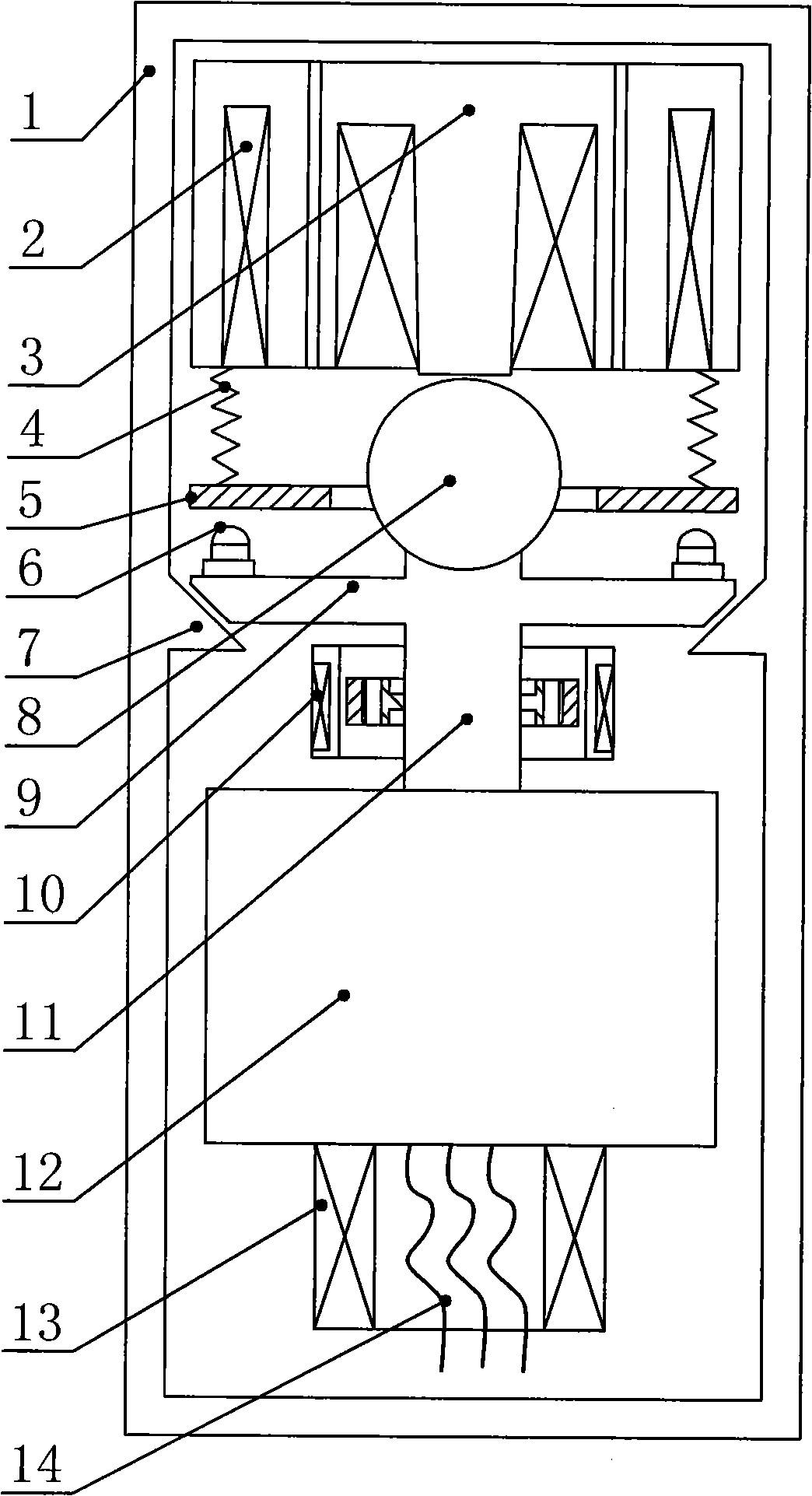

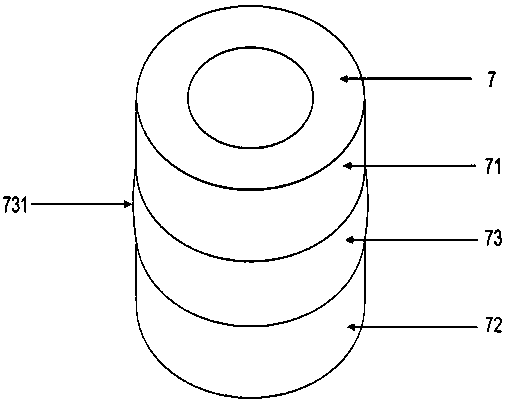

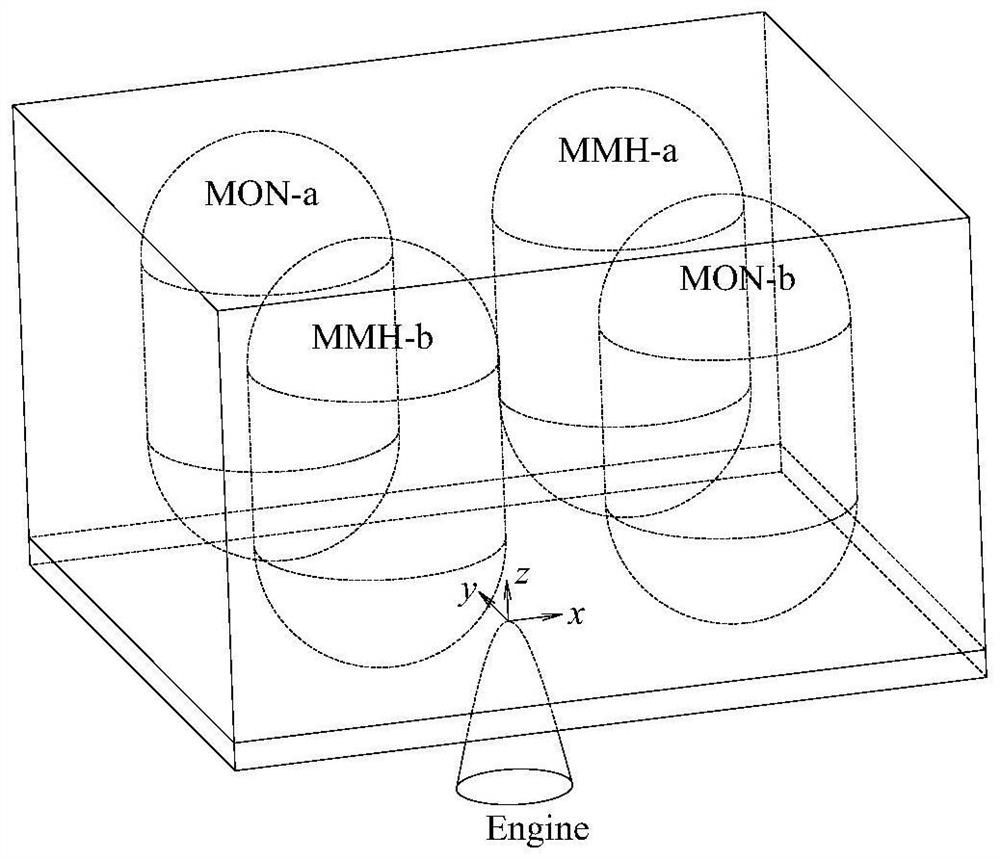

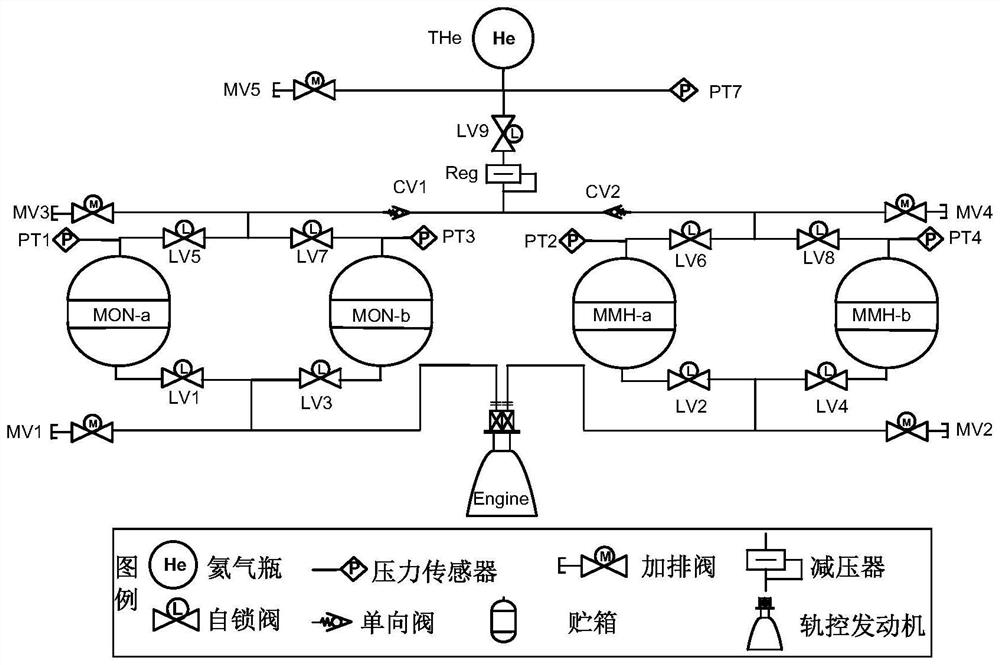

Method for reducing disturbance torque of orbital transfer engine by adjusting discharge of parallel storage tanks in real time

PendingCN114218771AInterference torque adjustmentSmall disturbance torqueDesign optimisation/simulationComplex mathematical operationsClassical mechanicsControl theory

The invention relates to a method for reducing disturbance torque of an orbital transfer engine by adjusting discharge of parallel storage tanks in real time. The method comprises the following steps: acquiring satellite input information; obtaining a matrix reflecting a storage tank mounting position and a system mixing ratio, a thrust vector under a satellite mechanical coordinate system and engine thrust action point information under the satellite mechanical coordinate system; determining a storage tank propellant filling amount, a satellite centroid, an engine thrust vector and coordinates of an intersection point of an XY plane at the satellite centroid when orbital transfer begins; the X-direction and Y-direction centroid adjustment target values and the like of the satellite in the orbital transfer process are iteratively calculated step by step according to time steps; and during orbital transfer of the satellite, related valves are operated on orbit according to the determined falling pressure / constant pressure mode of the storage tank, and discharge of the parallel storage tanks is adjusted in real time, so that the disturbance torque of an orbital transfer engine is reduced. The method comprehensively considers factors such as performance parameters and satellite loading precision errors of the engine, is close to engineering practice, facilitates engineering application and facilitates improvement of calculation precision.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Five-degree-of-freedom unilateral suspension-supported ball-disc flywheel integrated vehicle-mounted energy storage device

ActiveCN110112860BReduce axial sizeSuppress gyro effectElectric machinesMechanical propulsion powerCircular discMagnetic bearing

The invention discloses a five-degree-of-freedom single-side suspension supported ball flywheel integrated vehicle-borne energy storage device for an electric vehicle. The middle part of a flywheel rotor is a main disc body, the upper part is a spherical ring, the lower part is an outer ring and an inner disc, a circular groove is formed between the inner disc and the outer ring, and an outer rotor motor is in the circular annular groove. A circular outer wall of the spherical ring is an outwardly convex spherical surface, and an inner wall is an inwardly convex spherical surface. The uppermost end of a radial stator of a five-degree-of-freedom magnetic bearing is an upper end ring of a ring body, a radial outer ring stator yoke extends downward from an outer side wall of an upper end ring, a radial inner ring stator yoke extends downward from an inner side wall, a spherical groove is formed between inner side walls of a radial outer ring stator pole extending inward from an inner sidewall of a lower end of the radial outer ring stator yoke, a spherical groove is formed between inner side walls of a radial inner ring stator pole extending outward from an outer side wall of a lowerend of the radial inner ring stator yoke, and the spherical ring sleeves the radial inner ring stator pole and the radial outer ring stator pole, the axial dimension is reduced, and the gyro effect is suppressed.

Owner:JIANGSU UNIV

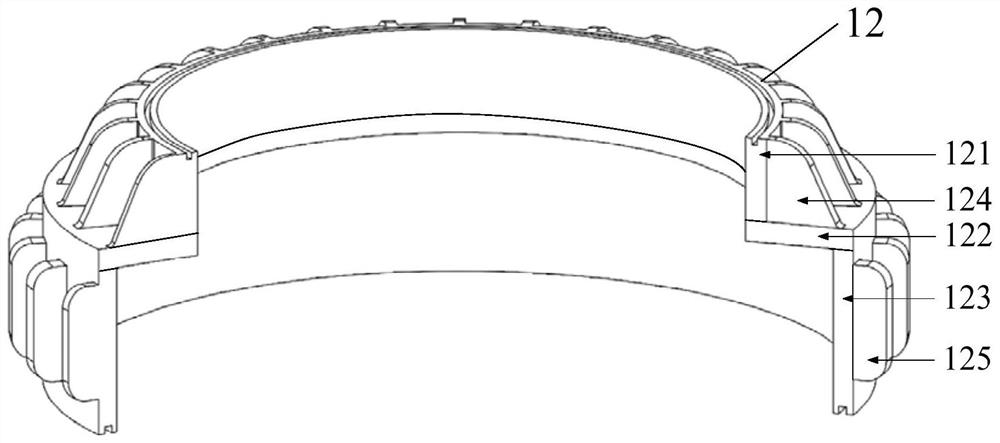

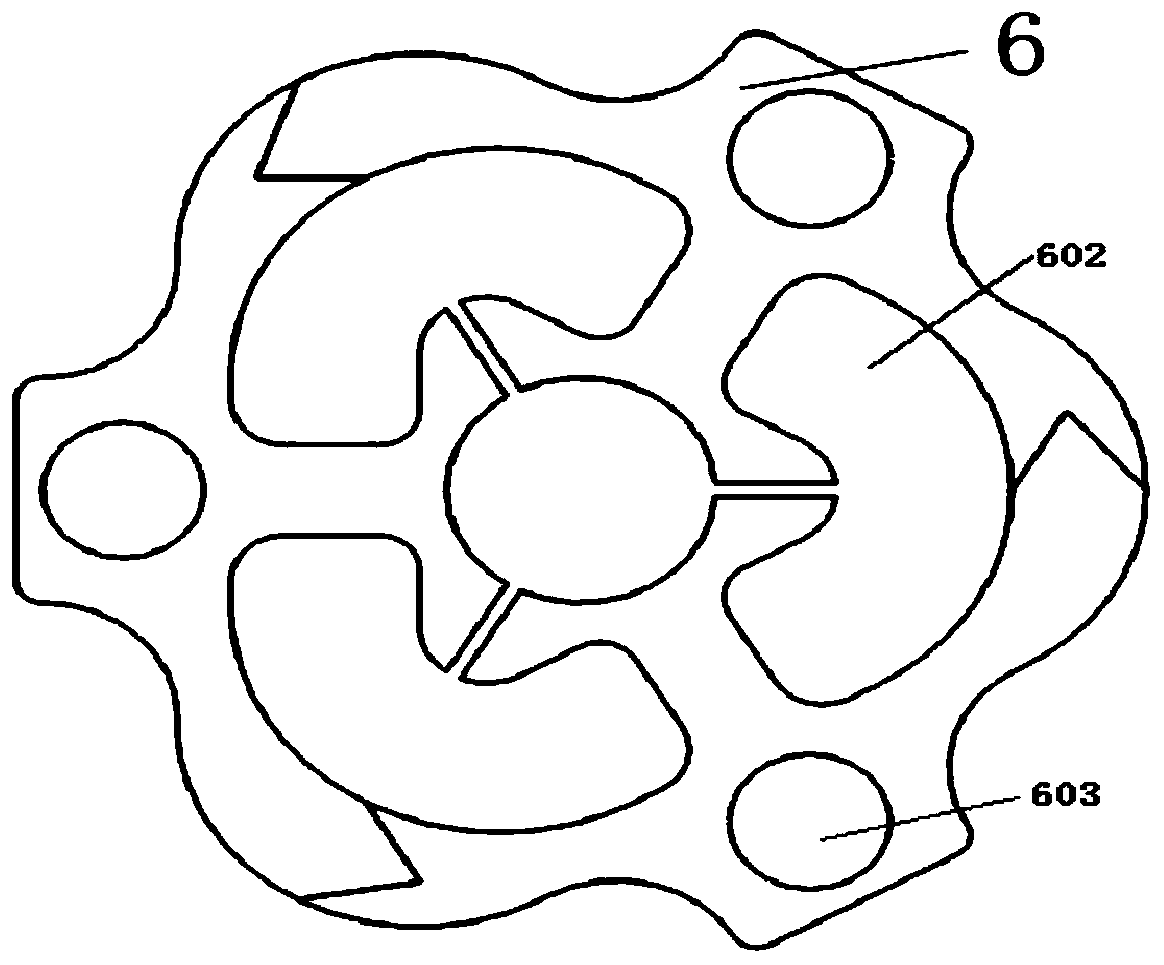

Sensor for three-floated gyroscope and stator preparation process thereof

PendingCN110926443AGyro precision and reliability guaranteeSolve the problem of zero dead zoneRotary gyroscopesStatorElectrical and Electronics engineering

The invention relates to a sensor, in particular to a sensor for a three-floated gyroscope and a stator preparation process thereof, and solves the problems of oil leakage of a sensor rotor and asymmetry of a sensor magnetic circuit of an existing moving-coil sensor device. The sensor rotor comprises a rotor bracket, a rotor coil and a rotor pouring sealant layer. The rotor support is an annular support, an annular groove is formed in the circumferential direction of the outer circumferential face of the annular support, and one side wall of the groove is a step face. The rotor coil is wound in the small end of the groove. The pouring sealant is poured in the large end of the groove along the outer peripheral surface of the rotor coil to form a rotor pouring sealant layer. The first end surface of the pouring sealant layer clings to the large end surface of the groove, and the second end surface of the pouring sealant layer is flush with the end surface of the rotor bracket. The sensorstator comprises an inner magnetic conductive ring and a plurality of magnetic poles, and the plurality of magnetic poles and the inner magnetic conductive ring are integrally arranged. By optimizingthe structure of the sensor, the center of mass of the gyroscope does not obliquely float in a certain slope trend any more, and the precision and reliability of the gyroscope are guaranteed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

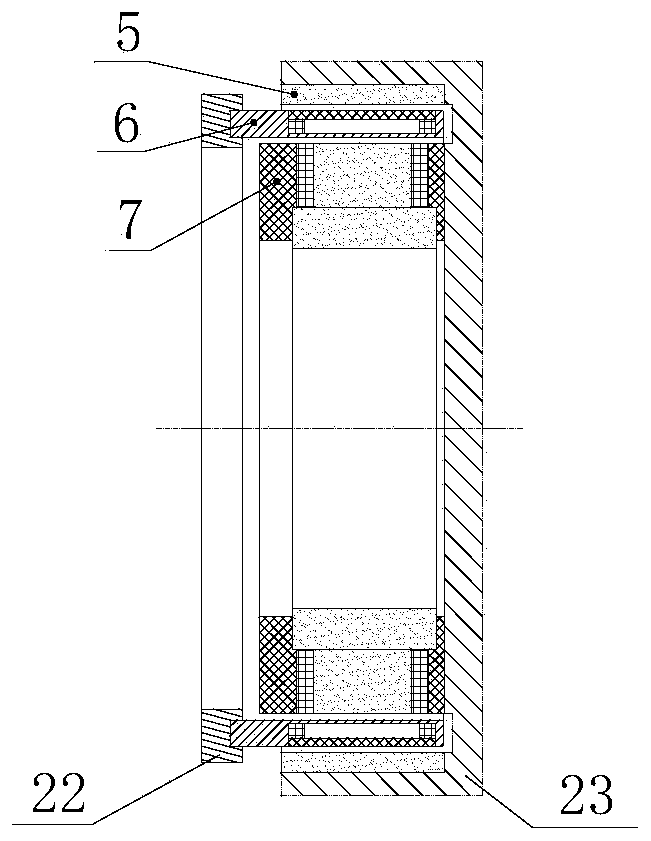

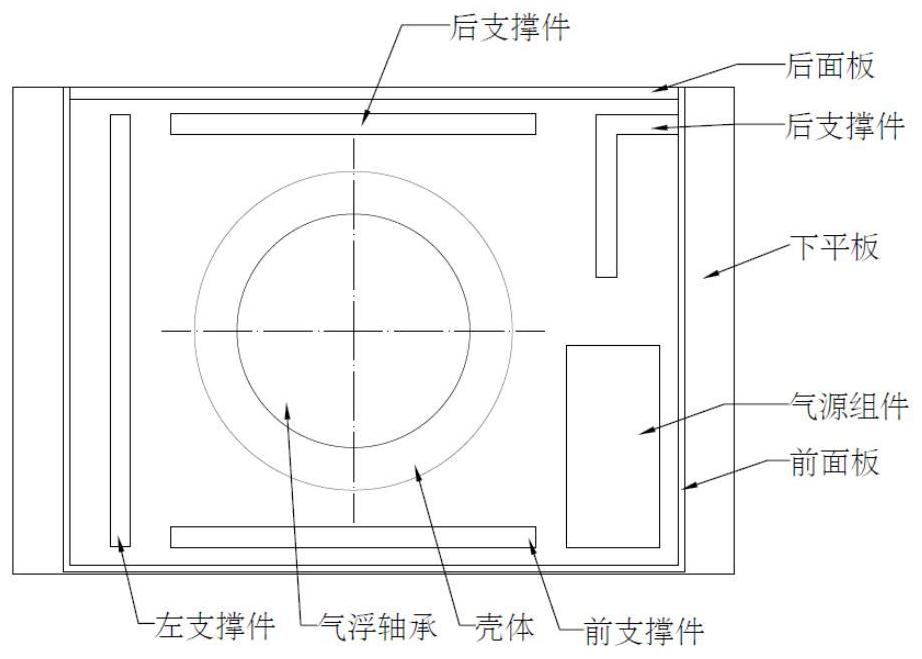

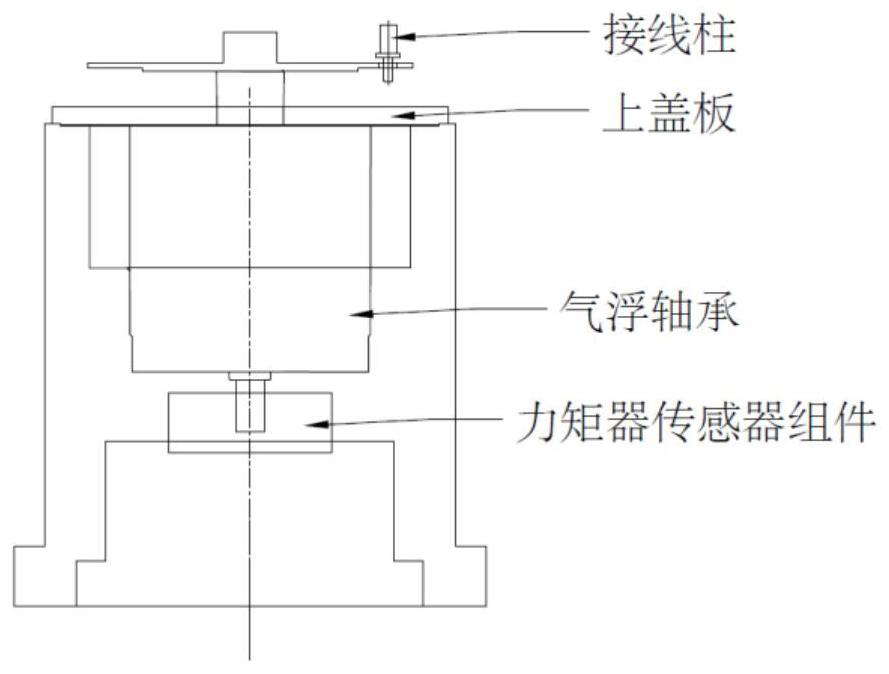

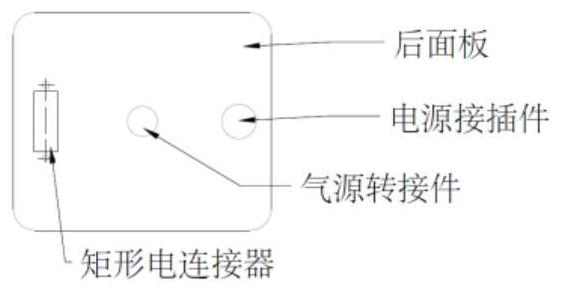

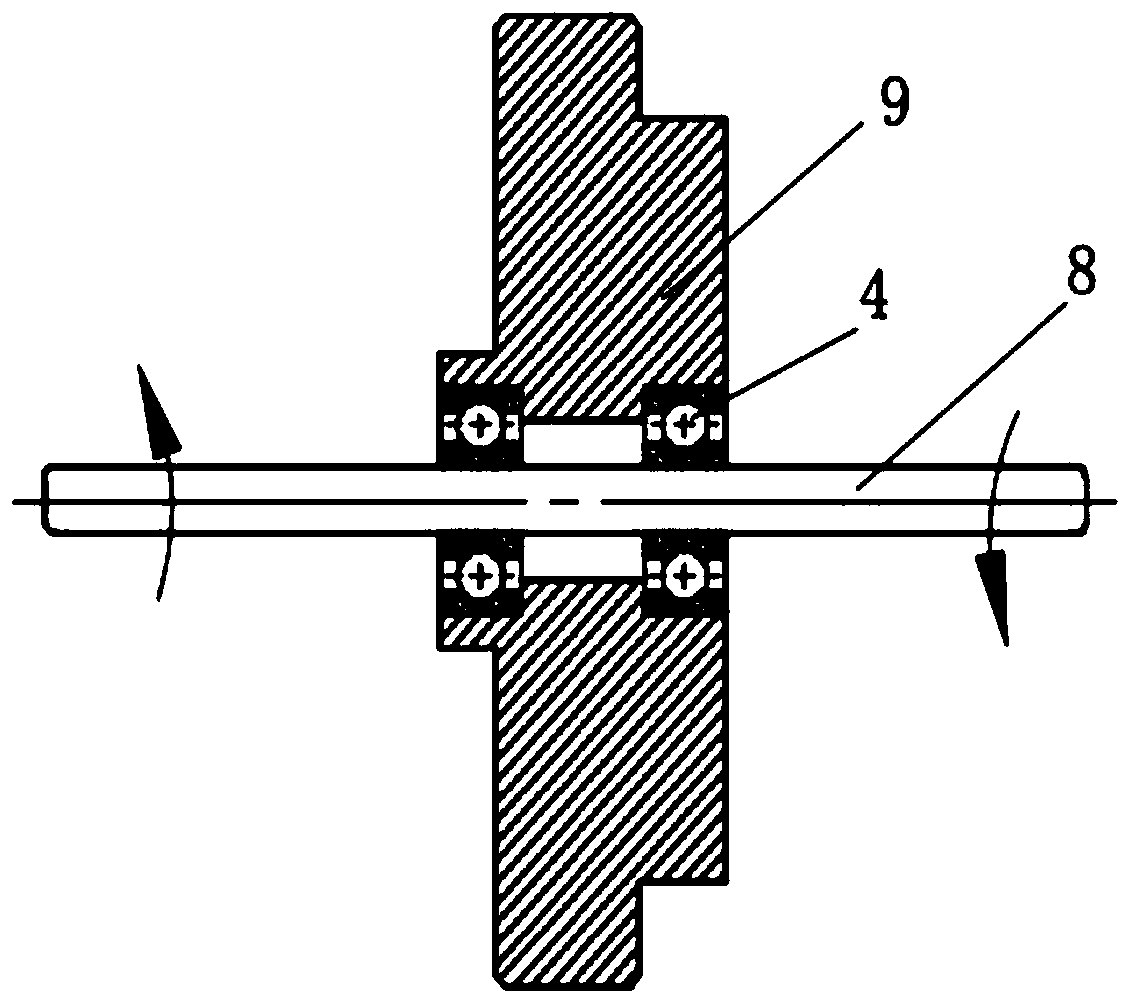

High-precision counter torque testing device for gyro motor

PendingCN114235244AIncreased sensitivityImprove test accuracyWork measurementTorque measurementAir bearingElectric machine

The invention discloses a high-precision counter torque testing device for a gyro motor, and the device comprises a lower flat plate installation housing, an air source assembly, a front support member, a rear support member, a left support member, a right support member, a housing installation torquer sensor assembly, an air bearing, and an upper cover plate, the air bearing is connected with a switching tool, a front panel is connected with the left support member and the right support member, and the upper cover plate is connected with the lower flat plate installation housing. The rear panel is connected with the rear supporting piece, a rectangular electric connector, an air source adapter and a power supply connector are installed on the rear panel, a torquer sensor assembly outgoing line is welded to the rectangular electric connector, an air source assembly and the air source adapter are connected with the air bearing through pipelines, and a binding post is connected with the power supply connector. The upper flat plate is connected with the left supporting piece, the right supporting piece, the front supporting piece and the rear supporting piece. When the device is used for testing, a to-be-tested motor is mounted on the switching tool to form torque acting on the rotor shaft of the air bearing, and the torque is converted into a voltage signal through the torquer sensor assembly and is transmitted to the upper computer.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Double-rail double-drive-based three-beat double-workpiece bench exchange apparatus and method thereof

InactiveCN102393612BGreat driving forceSmall inertiaPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistButt joint

The invention which relates to a double-rail double-drive-based three-beat double-workpiece bench exchange apparatus and a method thereof belongs to the technical field of semiconductor manufacturing equipment. The apparatus is characterized in that: the apparatus comprises workpiece benches which operate on a prealigned station and an exposure station; the prealigned station and the exposure station are respectively provided with a well type driving unit which comprises a two side X-directional liner motion unit and a two side Y-directional liner motion unit; two Y-directional transitional liner motion units are arranged between the two well type driving units; and the bench replacement of the double-workpiece bench is completed through the butt joint of the Y-directional liner motion unit and the X-directional liner motion unit. According to the invention, the two workpiece benches are driven in the prealigned station and the exposure station in a dual side mass center mode, so the system angle rigidity is increased; only three beats are needed to exchange the two workpiece benches between the prealigned station and the exposure station, so the lithography efficiency is improved; and the apparatus has the advantages of small motion inertial, short stable time, large structure rigidity and the like in the concrete embodiment process.

Owner:HARBIN INST OF TECH

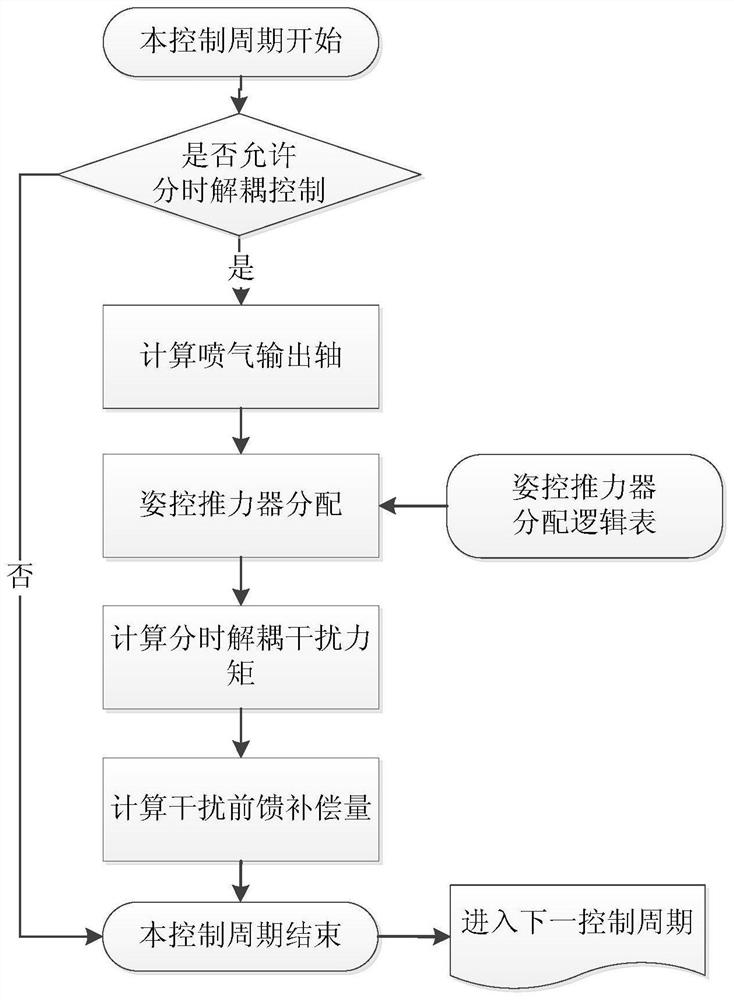

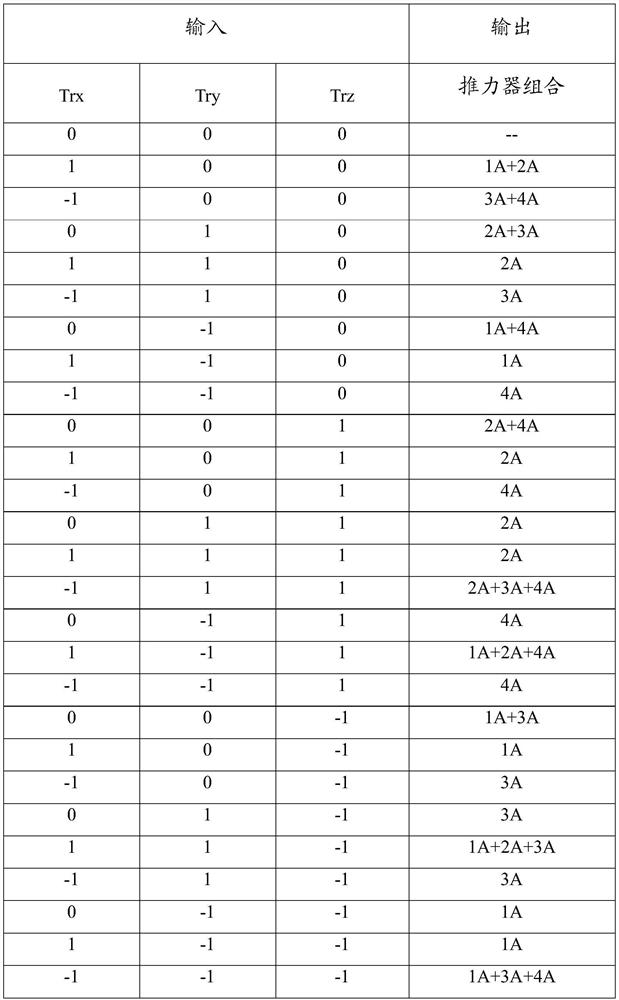

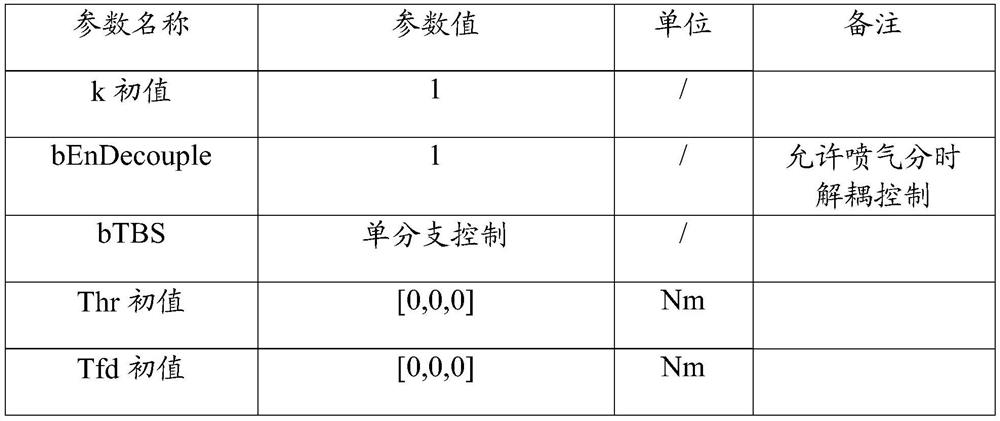

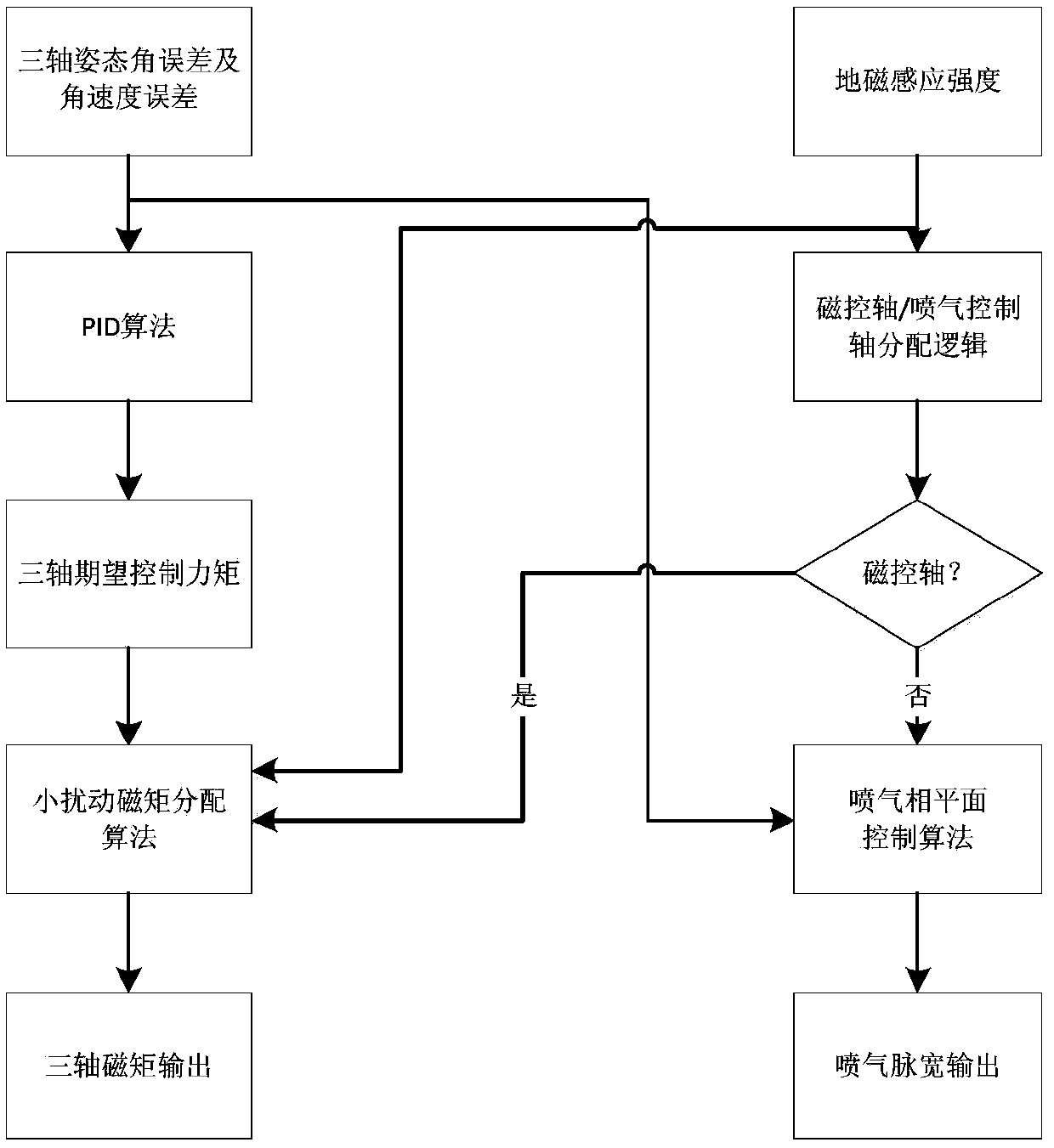

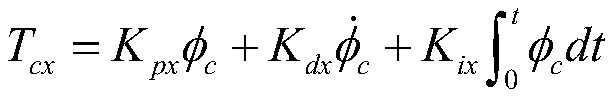

Three-axis decoupling attitude control method for thruster multiplexing

ActiveCN114019992ASmall disturbance torqueSolve the disturbance torque problemAttitude controlMultiplexingAttitude control

The invention relates to a three-axis decoupling attitude control method for thruster multiplexing, and belongs to the field of spacecraft attitude orbit control. The method comprises the following steps: (1) recording an initial value of a control period count k as 1, and if air injection time-sharing decoupling control is allowed, circularly carrying out steps (2) to (6); (2) calculating an air injection output shaft; (3) distributing attitude control thrusters; (4) calculating a time-sharing decoupling disturbance torque; (5) calculating an interference feedforward compensation amount; (6) if the air injection time-sharing decoupling control is forbidden, quitting the calculation process; otherwise, returning to the step (2), and adding 1 to k. According to the thruster torque output time-sharing modulation method, aiming at the thruster output coupling problem, a time-sharing modulation mode is adopted, three-axis air injection output torque decoupling is achieved, and the disturbance torque of an unexpected output shaft is reduced.

Owner:BEIJING INST OF CONTROL ENG

A three-degree-of-freedom spherical hybrid magnetic bearing with axial self-loop

ActiveCN108547867BGood for high speed operationIncrease speedShaftsEngine componentsCircular discMagnetic bearing

Owner:JIANGSU UNIV

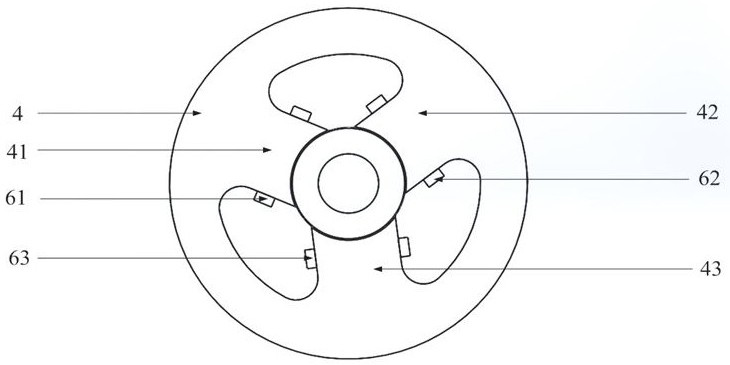

A high-precision attitude control method combining magnetic control and jet control with low working fluid

ActiveCN106081167BSave jet working fluidAvoid the shortcomings of low precision of magnetic control attitude controlArtificial satellitesAttitude controlWorking fluidAttitude control

The invention relates to a high-precision attitude control method combining magnetic control and jet control with labor-saving. The steps are: (1) calculate the expected control torque by using the PID control law according to the three-axis attitude error and the angular velocity error; (2) calculate the expected control torque according to the geomagnetic induction The real-time distribution of the intensity vector in the three-axis coordinate components of the satellite body coordinate system determines which axis attitudes implement magnetic control and which axis attitudes implement jet control; (3) use the small disturbance magnetic moment distribution algorithm to calculate the three-axis magnetic moments to fully satisfy the magnetic control The desired control torque of the shaft, while reducing the disturbance torque generated by the magnetron; (4) Using the jet phase plane algorithm to calculate the jet pulse width of the jet control shaft. The attitude control of the present invention has high accuracy, low working medium consumption, simple calculation and easy engineering realization.

Owner:BEIJING INST OF CONTROL ENG

A coaxial counter-rotating geomagnetic energy storage and release energy delivery ground experiment system and method

ActiveCN113075592BReduce power consumptionSmall sizeCosmonautic condition simulationsThree-component magnetometersTarget reachingControl theory

The invention discloses a coaxial counter-rotating geomagnetic energy storage and release energy delivery ground experiment system, which includes a supporting through shaft and a magnetic moment generating device, and a first target delivery component and a second target delivery component are installed on the supporting through shaft for coaxial rotation. Two target delivery components, the first target delivery component and the second target delivery component are used for the installation and release of the delivery target; its working method is that the first target delivery component and the second target delivery component are configured After receiving the signal of starting rotation of the magnetic moment generating device, the support shaft is used as the rotation axis to rotate in the opposite direction, and when the linear velocity at the delivery target reaches the linear velocity set by the system, the first target delivery component or the second delivery component The two-target delivery component releases the delivery target. The present invention adopts the method of two sets of delivery devices coaxially counter-rotating, which can overcome the air resistance moment in the ground experiment and remove the restriction of the upper limit of the target linear velocity, so that it can be better used for the verification of the ground principle of the geomagnetic energy storage method.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI +1

A Rotation Modulation Axial Spherical Pure Electromagnetic Bearing

InactiveCN105179477BEliminate distractionsImprove uniformityBearingsMagnetic bearingModulation function

A rotationally modulated axial spherical pure electromagnetic bearing, mainly comprising: an upper stator core, a lower stator core, an upper axial bearing coil, a lower axial bearing coil, a rotor, an upper axial air gap, a lower axial air gap, and a stator It consists of a mounting plate, a rotation modulation rotor bearing sleeve, a rotation modulation bearing, a rotation modulation rotor lock nut, an ultrasonic motor rotor, an ultrasonic motor stator, a rotation modulation stator bearing sleeve and a rotation modulation stator lock nut. Since the stator of the axial spherical pure electromagnetic bearing is driven by an ultrasonic motor, the rotation of the stator is realized, so it has a rotation modulation function, so it can eliminate the gyro drift caused by the rotation of the gyro rotor, and greatly improve the detection when it realizes the angular rate detection precision.

Owner:UNIV OF SCI & TECH BEIJING +1

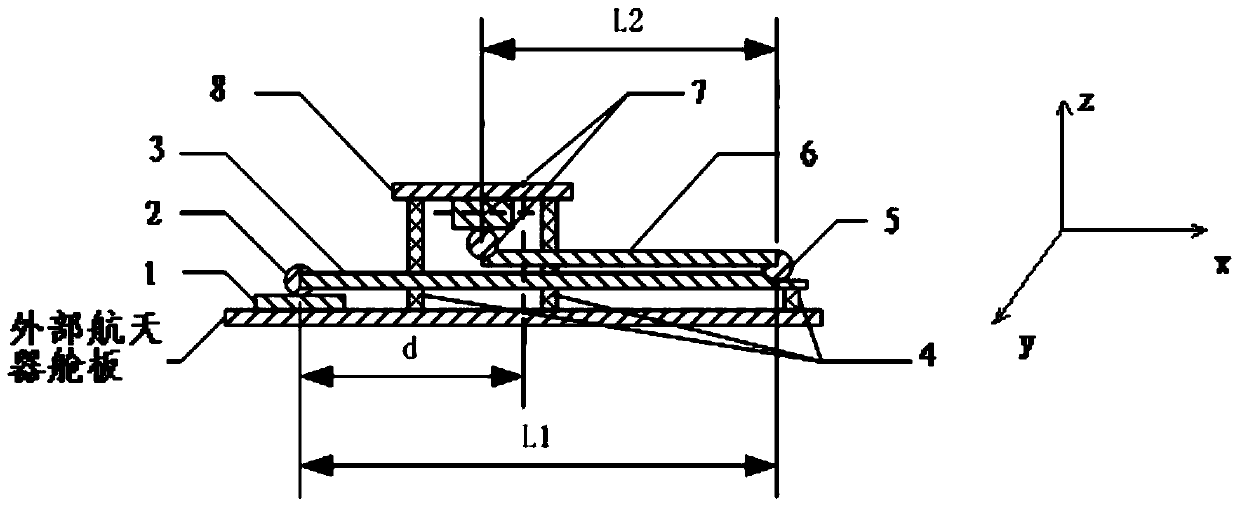

An electric propulsion deployment and thrust direction adjustment mechanism

ActiveCN108657469BIncrease the acceleration componentImprove utilization efficiencyCosmonautic propulsion system apparatusSpacecraft guiding apparatusSpacecraft propulsionControl theory

The invention relates to an electric propulsion expansion and thrust direction adjustment mechanism, and relates to the field of spacecraft propulsion adjustment. The electric propulsion expansion andthrust direction adjustment mechanism comprises a mounting bottom plate, an elastic expansion joint, a first expansion arm, locking mechanisms, a single-degree-of-freedom revolute joint, a second expansion arm, a double-degree-of-freedom revolute joint and a thruster mounting plate. The axial end of the first expansion arm is fixedly connected with the upper surface of the mounting bottom plate through the elastic expansion joint, the locking mechanisms are fixedly mounted on the lower surface of the first expansion arm, and the single-degree-of-freedom revolute joint is fixedly mounted on the other axial end of the first expansion arm. The axial end of the second expansion arm is connected with the first expansion arm through the single-degree-of-freedom revolute joint, the double-degree-of-freedom revolute joint is fixedly mounted on the other axial end of the second expansion arm, and the double-degree-of-freedom revolute joint is fixedly connected with the lower bottom surface ofthe thruster mounting plate. According to the electric propulsion expansion and thrust direction adjustment mechanism, the backup capability of an electric thruster is improved, and the consumption ofa propellant under the condition of fault ignition is reduced; and at the same time, the efficiency of the electric thruster to maintain the north-south position can be improved.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

High speed brushless DC permanent magnet motor for vacuum cleaner

ActiveCN105827089BImprove cooling effectImprove work performanceAssociation with control/drive circuitsMagnetic circuit stationary partsEngineeringPermanent magnet motor

The invention discloses a vacuum cleaner high-speed brushless DC permanent magnet motor comprising a shafting assembly, a stator assembly, and a drive controller. The shafting assembly comprises a rotating shaft, bearings, blades, and a magnet. The stator assembly comprises a stator, armature windings, a guide bar, and a motor base connected with the guide bar. The rotating shaft is connected with the motor base through the bearings. The magnet is installed at one side, near the stator, of the rotating shaft, and the blades are installed at the other side. The stator is formed by splicing armature tooth blocks, and is provided with stator slots and positioning holes. The stator slot of each armature tooth winds the corresponding armature winding. The stator is connected through the positioning holes with the guide bar for and is thus fixed. The stator is formed by splicing and combining more than three armature teeth. The motor base is provided with a center hole which is internally equipped with a bearing chamber in which the bearings are arranged. The motor base is connected with the rotating shaft through the bearings.

Owner:ONCE TOP MOTOR MFG

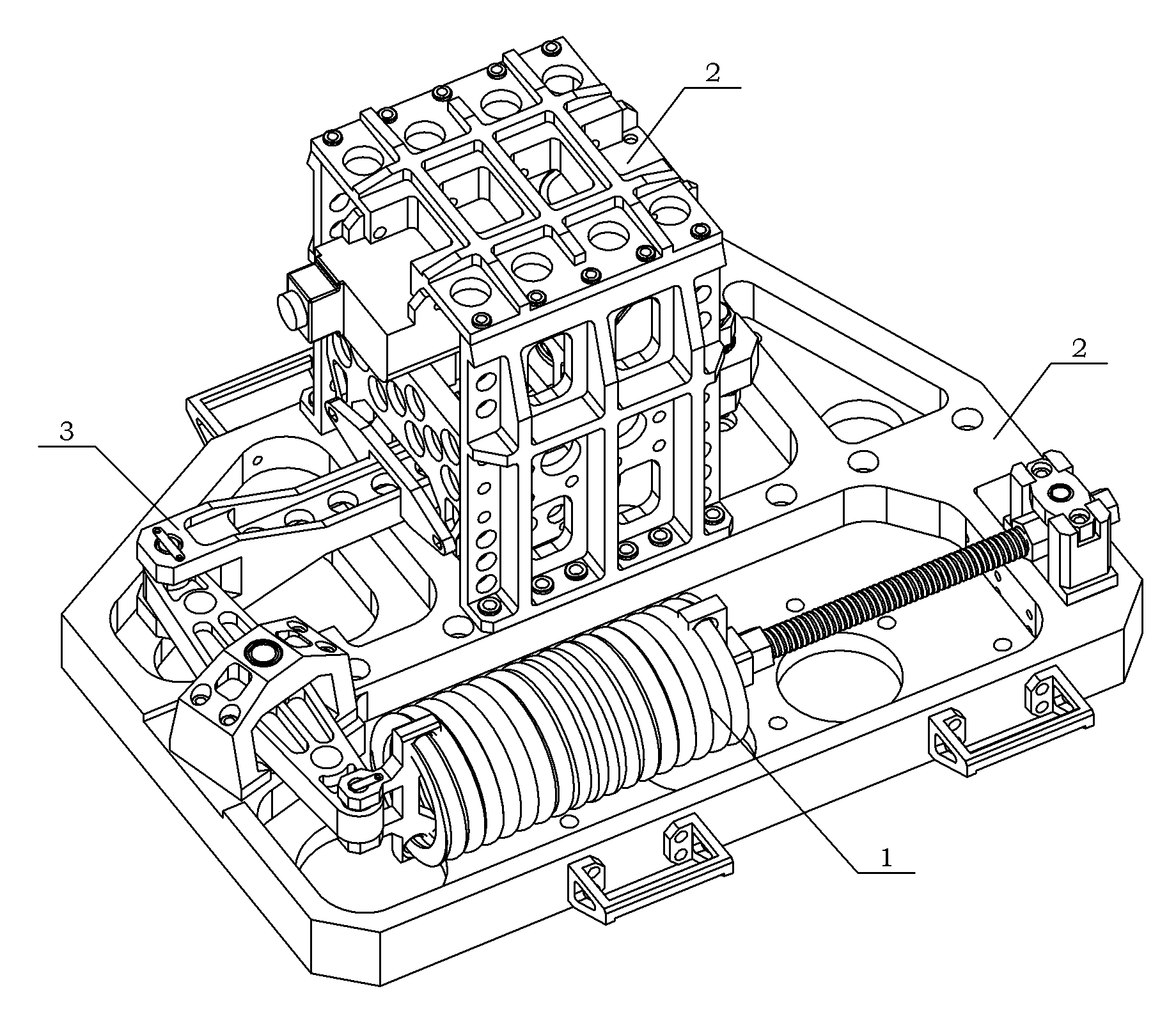

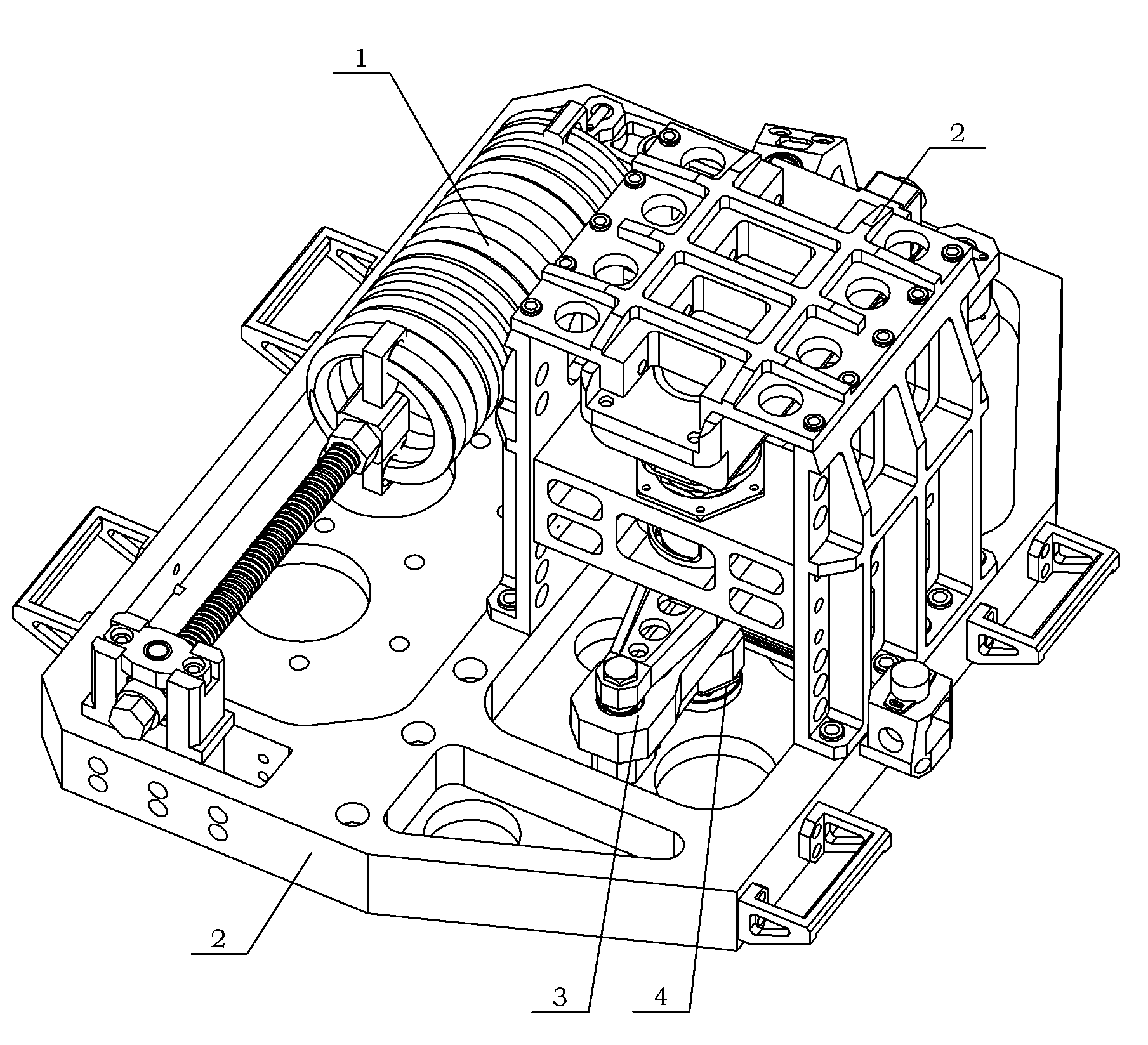

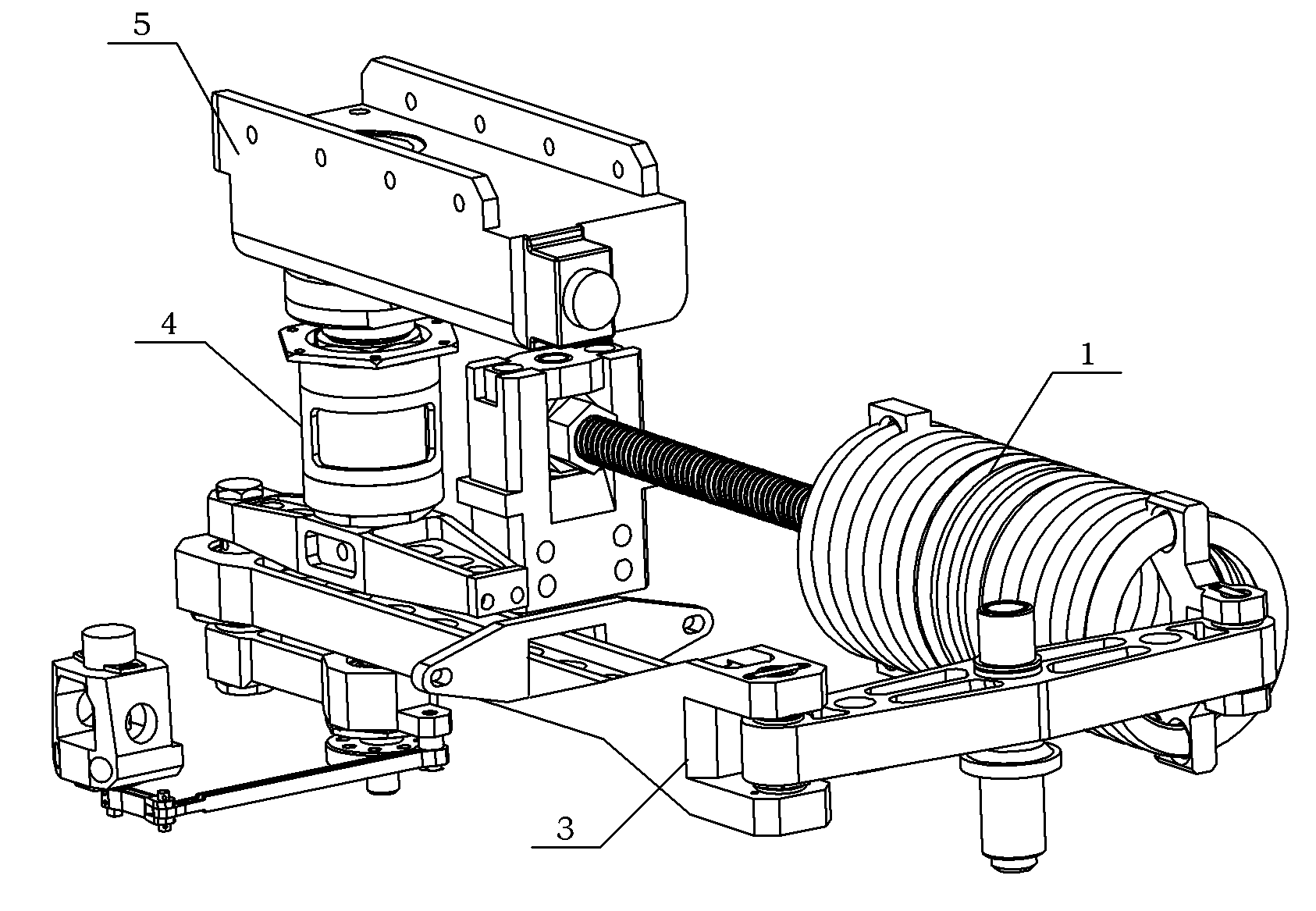

Load simulator based on follow-up moment load

The invention discloses a load simulator based on a follow-up moment load, comprising an elastic force application assembly, a framework assembly, a connecting rod assembly and a torque measurement assembly, wherein the elastic force application assembly, the connecting rod assembly and the torque measurement assembly are arranged on the framework assembly. The elastic force application assembly is used for loading pre-applied force with different gradients on a piece to be detected; the framework assembly is used for loading the follow-up moment load on the same platform; the connecting rod assembly is used for realizing force / torque effective transmission; and the torque measurement assembly is used for effectively measuring the loading torque of a piece to be detected and the rotating angle in the connecting rod assembly. The load simulator is load equipment containing a spring assembly, and the torque load requirements with the different gradients of the piece to be detected are achieved through adjusting the pre-tightening force of a spring through a screw lever. If the load spring cannot meet the requirements, the load spring is replaced by a spring with a different rigidity, and the hanging point of a first connecting rod is replaced so as to realize the torque load requirements with the different gradients. Furthermore, the load simulator can be used for detecting the dynamic rigidity and the static rigidity of the output end of the piece to be detected.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com