High-stability low-disturbance torque optimum design method of triaxial air bearing table

A high-stability, optimized design technology, applied in the field of simulation, can solve the problems that the air-floating table cannot float, cannot guide the design of air-bearing bearings, and has a great influence on the accuracy of the three-axis air-floating table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

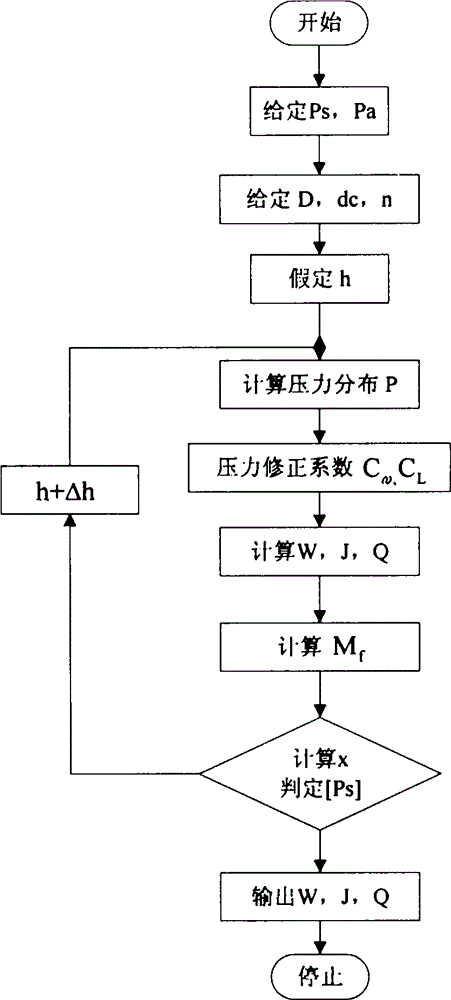

[0043] combine figure 1 , the optimal design method of the three-axis air bearing table of the present invention, the steps are as follows:

[0044] Step 1: First set the air supply pressure P s , Environmental pressure P a , according to many years of research and development experience, the air supply pressure is recommended not to be too large to avoid complicated air supply equipment; usually P s The initial value is set at 0.4 ~ 0.7MPa to ensure that the bearing capacity can be increased as much as possible and the diameter of the ball can be reduced to create favorable conditions for precision machining without "air hammer";

[0045] Step 2: Given the diameter D of the sphere and the diameter of the orifice d c , the number of restrictors n;

[0046] Step 3: The thickness of the air film of the ball bearing is h, and the initial value is not less than 10 μm.

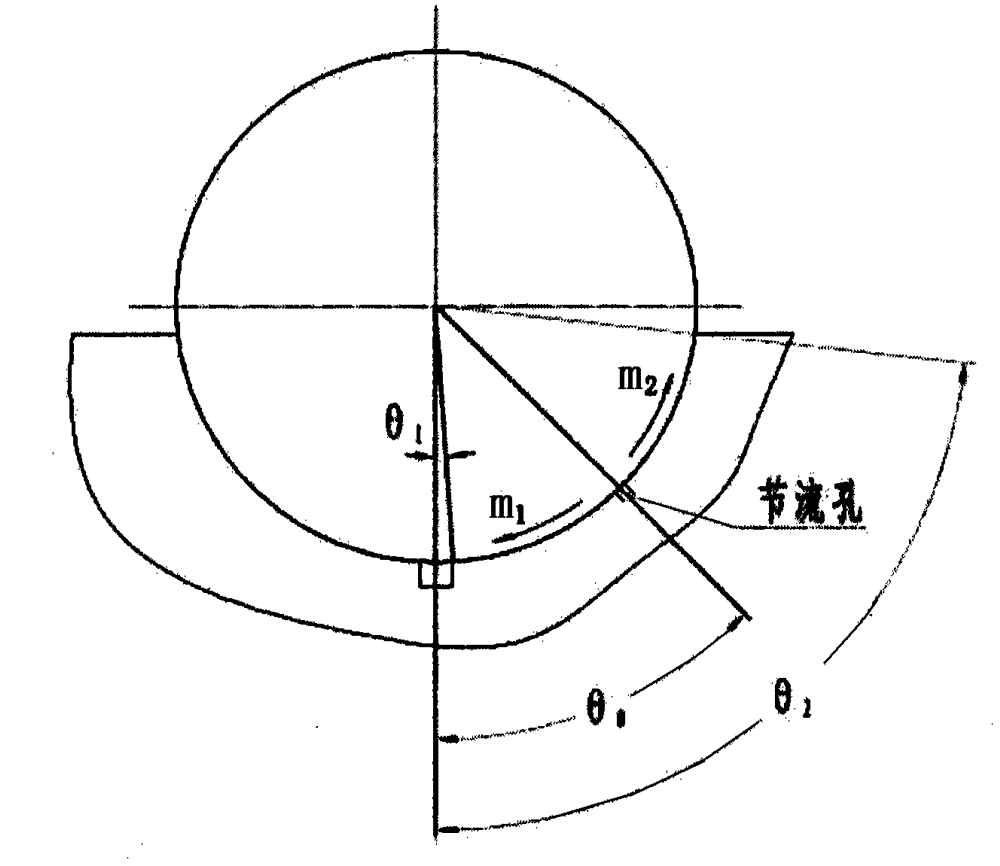

[0047] Step 4: Calculate the pressure distribution P and the bearing mass flow m by using the vertical proj...

Embodiment 2

[0074] In the optimization design of air-floating ball bearings, usually its load-carrying capacity is appropriately higher than the index requirement, which is usually taken as 110% to 120% of the index value, so as to ensure that the bearing has ample load-carrying capacity.

Embodiment 3

[0076] In the optimization design of the air bearing ball bearing, various technical requirements are considered comprehensively, and the design principle is to adopt the best stiffness design of the air film under the condition of satisfying the carrying capacity.

[0077] In principle, the value of the air film is not less than 10 μm. This medium-level air film thickness not only ensures the performance of the bearing but also reduces the difficulty of processing. Considering the existence of processing errors in spherical bearings: including size errors, shape errors, etc. In the case of force deformation, etc., it can still ensure a complete air film, realize full gas lubrication, and ensure the stability of the air bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com