Device and method for exchanging of double workpiece tables on lintel type single/double guide rails in double-drive stepping scanning

A technology with double worktables and double guide rails, which is applied in the direction of photolithography exposure devices, microlithography exposure equipment, etc., can solve the problems of large influence on the overall dynamic performance, affecting the dynamic performance of the system, and large reaction force of the abutment, etc., to achieve The single-chip processing cycle is shortened, it is beneficial to control characteristics, and the effect of large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

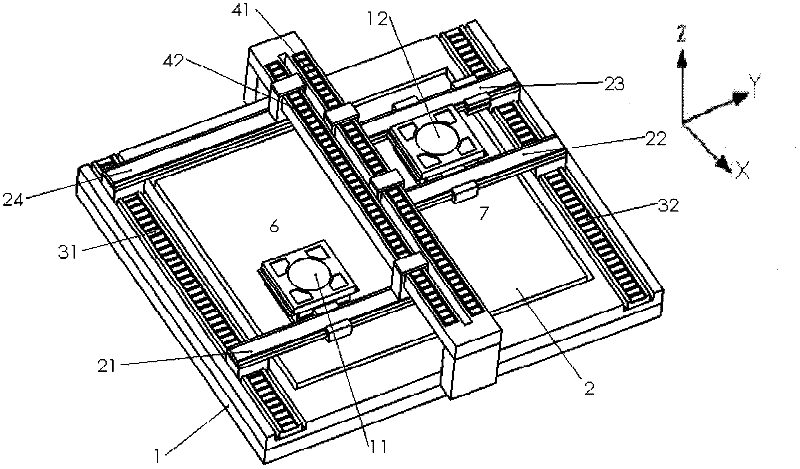

[0025] A lintel-type single / double guide rail dual-drive step-scanning double-workpiece stage exchange device, which includes a first wafer stage 11 running on the pre-processing station 6 and a first wafer stage 11 running on the exposure stage set on the same base 1 The second wafer stage 12 of the station 7 is provided with four first, second, third, and fourth linear motion units 21, 22, 23, and 24 in the Y direction on the four edges of the base 1, respectively, One first and second linear motion units 31 and 32 in the X direction are arranged on the symmetrical sides of the base 1, and two lower bottom surfaces along the X direction are arranged in the middle of the base 1 than the first and second. The lintel type first and second linear motion units 41, 42 on the working surfaces of two silicon wafer stages 11, 12; 1. The second, third, and fourth linear motion units 21, 22, 23, 24 and the first and second linear motion units 31, 32 in the X direction perform X-Y motio...

Embodiment approach 2

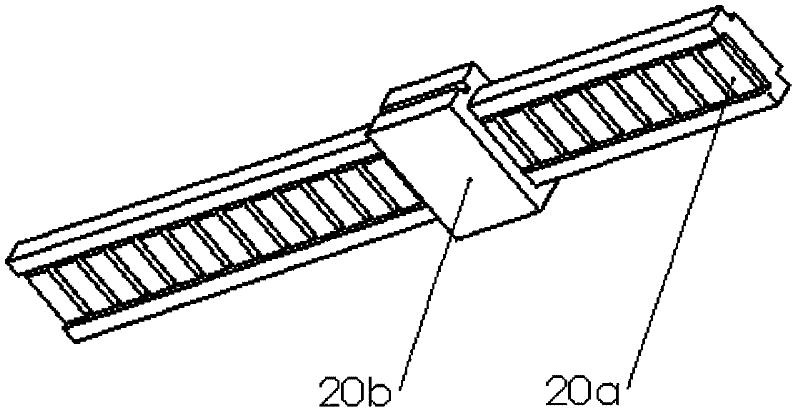

[0031] Such as Figure 10 As shown, the structure of the two lintel-type first and second linear motion units 41 and 42 placed in the middle of the abutment in Embodiment 1 is modified to obtain Embodiment 2. In Embodiment 1, the first and second linear motion units 41, 42 of the lintel type are composed of linear motors and air bearing guide rails, while in Embodiment 2, the new first and second linear motion units 41, 42 of the lintel type are not Contains linear motor structure, but only air bearing guide. Compared with Embodiment 1, in Embodiment 2, the drive in the X direction is changed from double drive to single drive, because the silicon wafer stage at the exposure station still adopts double guide rails and double drive in the Y direction, so the angular rigidity is large and the resistance is high. The advantages such as torque still exist; at the same time, because the single drive is used in the Y direction, the inconsistency of the driving force at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com